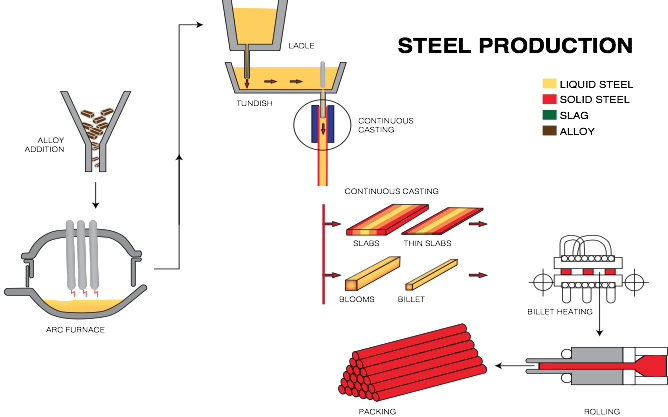

Damage Mechanism is a general term used to describe mechanical or chemical processes that result in equipment damage or material degradation. These can range from corrosion, to cracking, to heat damage, and everything in between.

When assessing damage mechanisms, one must take into account the current state of the equipment, as well as any potential damage the mechanism may cause later. Equipment’s susceptibility to a particular damage mechanism is affected by a number of variables, including materials of construction, process fluids, operating conditions, external environment, etc. A good understanding of the variety of damage mechanisms that exist is a must for any mechanical integrity program.

A thorough damage mechanisms review is essential for creating an effective inspection strategy. Once damage mechanisms and morphology are understood, inspection strategists can use this information to select inspection methods with the highest probability of detecting, characterizing, and measuring potential damage. Furthermore, inspection intervals can be established using industry codes and standards such as API 510, 570, 653, API RP 579 for fitness-for-service, and API 580 and 581 for risk-based inspection.

Some of the most common damage mechanisms in the refining and chemical processing industries are:

-

Corrosion Under Insulation (CUI), which occurs when moisture builds up on the surface of insulated equipment.

-

Sulfidation Corrosion, a type of corrosion that occurs at temperatures above 500°F (260°C) due to sulfur compounds in crude.

-

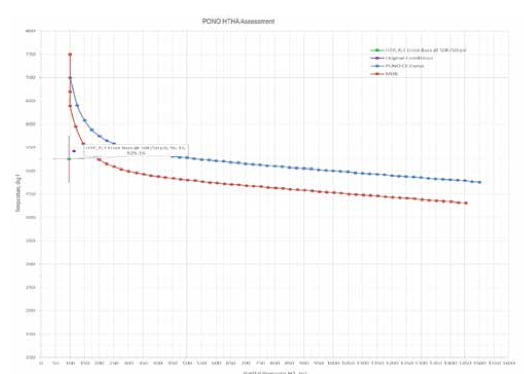

High Temperature Hydrogen Attack (HTHA), a mechanism that can affect equipment that is exposed to hydrogen at elevated temperatures (at least 400°F or 204°C)

-

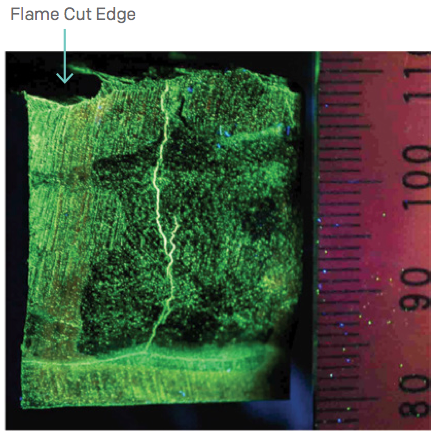

Wet H2S Damage, which can occur when atomic hydrogen from wet H2S corrosion reactions enters and weakens the steel.

-

CO2 Corrosion, which is a form of degradation that occurs when dissolved CO2 in condensate forms carbonic acid, which corrodes steels.

-

Hydrogen Embrittlement, which happens when atomic hydrogen infuses into certain higher strength steels and causes them to become brittle

-

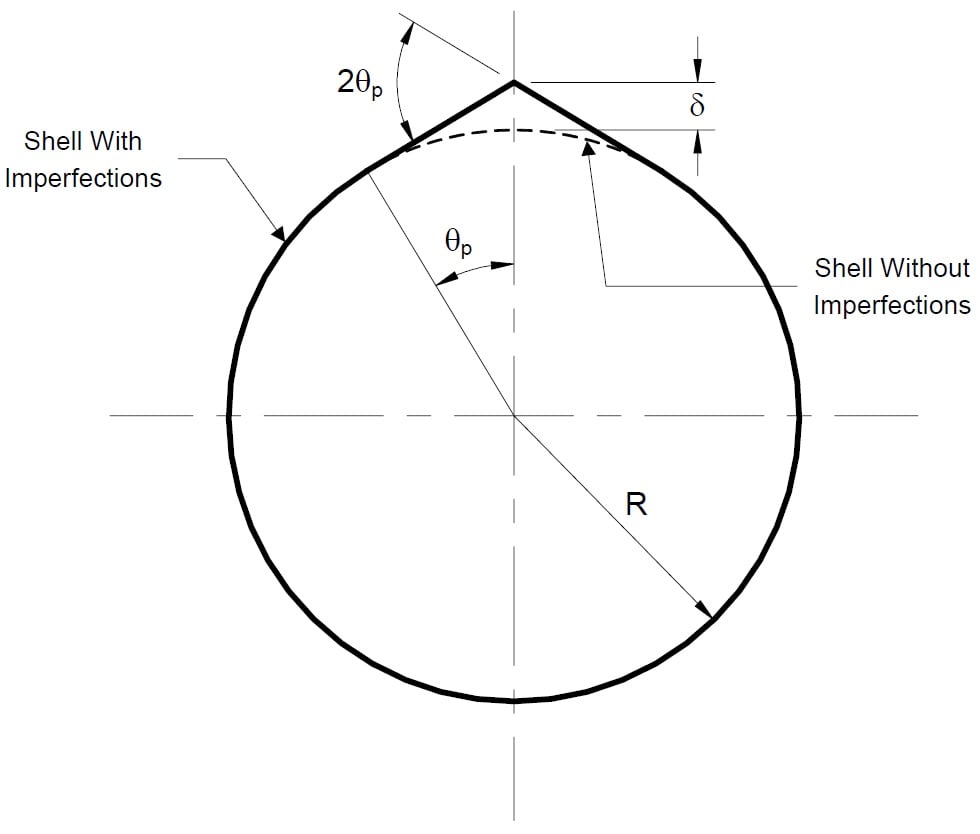

Brittle Fracture, which is the sudden, very rapid fracture under stress where the material exhibits little or no evidence of ductility or plastic degradation before the fracture occurs.

- Phosphoric Acid Corrosion is an acidic environment "disease" largely associated with polymerization units using phosphoric acid as a catalyst. Dry phosphoric acid catalyst is not corrosive to carbon steel, but wet phosphoric acid can corrode carbon at thousands of mils per year. This type of corrosion can often be found in dead zones and crevices where wet acid can drop out. In places where water is present, upgrading to 304L, 316L, or Alloy 20 may be necessary to prevent this type of corrosion, depending on the temperature.

Damage mechanisms are detailed and covered at length in API RP 571, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry. This document provides an in-depth look at over 60 different damage mechanisms that can occur to process equipment in refineries. It includes a general description of the damage mechanism, susceptible materials of construction, critical factors, inspection method selection guidelines, and control factors.

Related Topics

- Cathodic Protection

- Coatings

- Condition Monitoring Locations (CMLs)

- Corrosion Control Documents (CCDs)

- Positive Material Identification (PMI)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition