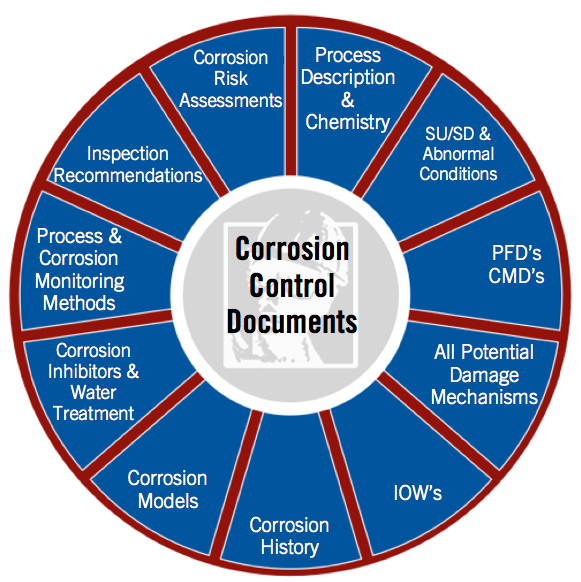

A Corrosion Control Document (CCD), sometimes also known as a corrosion report, corrosion manual, or critical process variable, is a document responsible for summarizing a unit's process description and its corrosion circuits. This includes the damage mechanisms in each circuit, as well as startup and shutdown corrosion influences. CCDs are an essential part of any risk-based inspection plan, allowing facilities to keep track of every element of operation, and allowing top efficiency and minimal shutdown times.

While the document is called a “corrosion control document," it can cover mechanisms aside from just corrosion. Mechanisms such as fatigue cracking, hydrogen embrittlement, and brittle fracture are covered as well. These documents are incredibly useful because they are able to provide an understanding for how to spot and avoid these mechanisms and how the mechanisms could afflict fixed equipment in service should they appear. This can help users avoid unexpected deterioration or damage of equipment and materials.

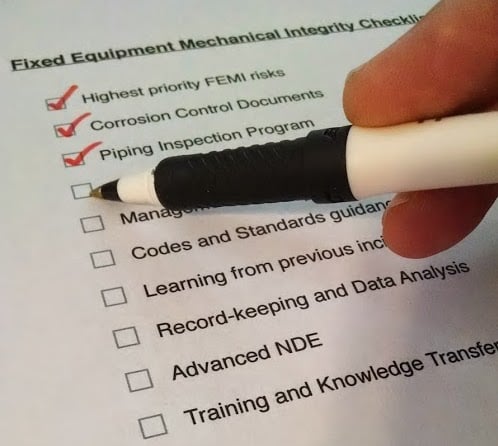

A proper CCD will usually include at least the following information:

-

A description of the unit;

-

Any operating conditions, such as shutdown or startup, that may affect certain damage mechanisms;

-

Process flow and corrosion loop diagrams;

-

A list of probable damage mechanisms and failure modes, along with information on each;

-

Recommended inspection practices; and

-

Applicable integrity operating windows (IOWs)

API RP 970 is a recommended practice that provides users with the basic elements for developing, implementing and maintaining CCDs for a refinery, and at the owner's discretion, may be applied at petrochemical and chemical process facilities.

In a way, CCDs are similar to API RP 571, which provides an in-depth look at over 60 different damage mechanisms that can occur to process equipment in refineries. This is nearly every damage mechanism known to the refining and petrochemical manufacturing industries. A CCD on the other hand will cover a small fraction of those mechanisms (those which apply to the equipment the document covers), but will cover those mechanisms in much greater detail, and in ways that apply specifically to the piece of equipment being covered.

Related Topics

- Cathodic Protection

- Coatings

- Condition Monitoring Locations (CMLs)

- Damage Mechanisms

- Positive Material Identification (PMI)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition