Ralph E. King P.E.: About the Author

Senior Staff Consultant, Stress Engineering Services Inc.

Ralph E. King is a 35-year experienced mechanical engineer with a broad range of technical experiences. Mr. King has extensive experience in evaluating equipment for auto-refrigeration and brittle fracture potential utilizing API-579 / ASME FFS-1 methodologies coupled with subject focused process hazards analysis (PHA) methods. His current responsibilities include providing staff technical support for the SES Plant Services Division which includes reliability engineering, equipment fitness-for-service evaluations, fixed equipment design, selection and evaluation, leading process hazards evaluations and incident investigations.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

There is concern in the industry over recent findings of reduced toughness fittings and flanges at risk of brittle fracture. This article provides an overview; possible contributors; measures taken to address; and a proposed FFS approach to address the issue.

An overview of process piping vibration and evaluating piping systems in vibration service to reduce harmful vibrations.

To ensure the mechanical integrity and fitness-for-service (FFS) of equipment, facility managers, reliability engineers, and inspection technicians must understand the HTHA damage mechanism.

Recently, Inspectioneering Journal sat down with Stress Engineering’s Bobby Wright and Ralph King to discuss how companies can better transfer and preserve industry knowledge.

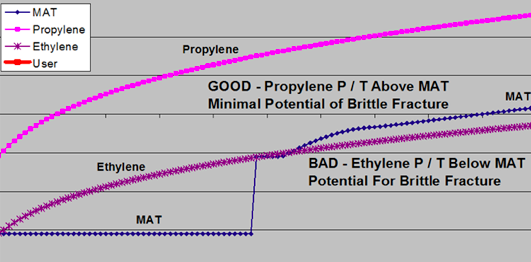

Auto-refrigeration is a process where an unintentional and/or uncontrolled phase change of a hydrocarbon from a liquid state to a vapor occurs, resulting in a very rapid chilling (refrigeration) of the liquid containing local equipment and/or piping. This phenomenon can result in a catastrophic ‘break-before-leak’ scenario commonly referred to as brittle fracture.