Greg Garic, P.E.: About the Author

Senior Staff Consultant, Stress Engineering Services, Inc.

Greg Garic has over 40 years of experience in pressure systems engineering, particularly in the fitness-for-service assessment of fixed equipment in chemical plants and refineries. He is highly experienced in stress analysis, fracture mechanics, finite element analysis, creep, and high-temperature material behavior. Mr. Garic's practice routinely involves evaluating and troubleshooting various fixed equipment problems such as corrosion, crack-like flaws, hot spots, creep, deformation, and many other issues.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

A discussion of key elements of piping analysis software for those considering its use in fitness-for-service assessments.

Part 8 of API 579 provides valuable techniques for simple and conservative closed-form solutions, which can be quicker and easier than an FEA.

Miner’s rule remains the most used fatigue damage accumulation approach in the oil and gas industry.

Real-world cracks don’t often resemble the idealized cracks on which fracture mechanics solutions are based. This is when categorization rules come into play.

The API 579 Committee has been steadily working for 10 years on a procedure to evaluate vibration in piping systems. That long work is about to pay off.

A discussion on the rationale for being cautious with an inspection of older vessels and how to decide when such inspection is appropriate.

Local thin area (LTA) assessments rarely fail. It happens, but not often. Let’s look at examples of how significant an LTA can be and still pass an assessment.

Ferritic materials change in toughness as a function of temperature, but the change is non-linear and happens at different temperatures for different materials.

Discussion on the new Annex 9J procedure with examples using the Part 3 exemption curve, the 9J General Procedure, and the 9J Simple Procedure.

A closer look at the evolution of remaining strength factors (RSF) from its mention in early papers to the latest edition of API 579.

The latest edition of the API 579-1/ASME FFS-1 Fitness-for-Service Code was released at the end of 2021. It seems like a good time to have a conversation with the Chair of that committee, Ben Hantz, to get his perspective on the evolution of FFS.

As one of the simpler API 579 FFS assessments, there are relevant criteria to check that are necessary to assess and evaluate laminations.

This article discusses some of the common fitness-for-service (FFS) issues plant engineers in the chemical and refining industry are facing and a handful of recommendations on how to improve them.

Component type is important when assessing the applicability and limitations of a particular assessment (Part and Level) to a particular component. This article explains the evolution of component type definition over the years.

There are many excellent changes and updates in the new edition of API 579, including significant technical changes and improvements. In this FFS Forum article, I’ll go through many of what I believe to be the most important changes.

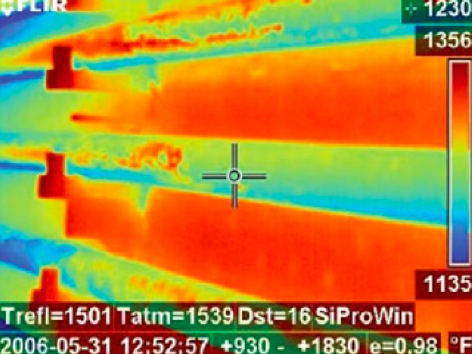

This follow-up article discusses the important topic of establishing Heat Exposure Zones and Level 1, 2, and 3 fitness-for-service assessments following a plant fire.

Part 1 presents a brief overview of the process of assessing equipment in a post-fire "return-to-service" effort and discusses some common issues that may arise during that process.

This article addresses some of the advantages and disadvantages of acoustic emission testing and discusses a few examples of its typical applications.

FFS assessments usually originate from inspection results and often end with a recommended inspection plan. This FFS Forum tries to provide a little better understanding of one particular inspection method: Acoustic Emission Testing.

The first two parts of this series covered the basics of fracture mechanics and how the FAD is interpreted. This article touches on a few practical points regarding the application of fracture mechanics in a plant environment.

Every fitness-for-service (FFS) assessment must have a well-defined acceptance criterion. For many damage mechanisms, it’s the “remaining strength factor” (RSF). But for crack-like flaw assessment, it’s the Failure Assessment Diagram, or FAD.

Fracture mechanics is a branch of engineering that describes the behavior of cracks – how they grow and when they fracture. Fracture of cracks is particularly dangerous because it can happen without warning under normal operating conditions.

Assessment procedures in API 579 are organized by damage mechanism. But what happens when different damage mechanisms are in play since the evaluation criteria may not be compatible?

There are many places where brittle fracture risk can sneak into your plant and many reasons why a new or revised brittle fracture assessment may be required when reviewing your pressure systems. Don’t overlook this dangerous failure mechanism.

FMR is a useful tool in many situations. It allows nondestructive evaluation of the surface microstructure that is entirely adequate in many cases. However, it is not a panacea, and there are many conditions where it is inadequate.

There are many sources and occurrences of metal fatigue in the chemical and refining industries. They range from low-cycle thermal stresses in an FCCU, to the relentless pressure cycling of a PSA, to the ultra-high cycles of a rotating pump.

A cornerstone of Level 1 and 2 metal loss assessment methods in API 579 is the concept of measuring thickness on a grid and constructing a “critical thickness profile.” These concepts are fundamental to Level 1 & 2 assessments in both Parts 4...

MSDs are an important, but often misunderstood, element of FFS analyses. This column will help readers understand what an MSD is and why it is so important to Fitness-For-Service analysis under API 579.

This is the second of a two-part column on “Creep.” This second part discusses the approach to creep assessment in plant equipment.

This is the first of a two-part column on “Creep”. It presents an engineering overview of the phenomena, answers the question: “What is Creep?”, and provides readers with foundational knowledge for evaluating and managing remaining...

Brittle fracture and material toughness issues are important concerns in equipment design and FFS. These issues increase when temporary start-up and shutdown conditions require more detailed assessments than provided for in vessel and piping codes.

The distinction between primary and secondary loads is certainly important in analysis of pressure systems. But this distinction is also important for plant operations and reliability engineers to keep in mind when dealing with day-to-day problems.

In this edition of the FFS Forum, Greg addresses some issues associated with inspection of vessels that have been in service for a number of decades, and offers some tips for reliability and inspection to follow when inspecting these older vessels.

In this column, I touch on what I see as an underused FFS technique for corrosion assessment: point assessment of corrosion – a technique that does NOT require a thickness grid. The reason I find this technique useful is largely because it’s so...

API 579-1 is a complex document covering several different types of equipment that may contain flaws or damage. Due to its complexity, this article condenses it into six things you need to know.

Predicting the remaining life of components operating in the creep regime is one of the trickiest problems encountered in the fitness-for-service (FFS) world.

If an operator finds cracking in a furnace waste heat boiler, excessive thinning in an absorption tower, or severe bulging in a converter, FFS assessments—not standard code analyses—are needed to evaluate the unit’s mechanical...