Jeremiah Wooten: About the Author

Managing Partner, Inspectioneering

Jeremiah Wooten joined Inspectioneering in 2013 after several years practicing O&G law in Dallas, TX. He currently serves as Managing Partner and General Counsel for the company, where his primary roles involve business development, strategic marketing, corporate relations, and managing the organization's legal department. Mr. Wooten holds a Bachelor of Arts and received his Juris Doctor from the University of Oklahoma.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

The 12th “Meeting of the Minds” roundtable hosted by Inspectioneering and Pinnacle focused on software advancements and new NDE technologies.

Inspectioneering and Pinnacle co-hosted the 11th “Meeting of the Minds” roundtable discussion focused on organization capability and competency development.

The focus of the 10th "Meeting of the Minds” roundtable discussion was on data validation and the importance of having consistent definitions of “good data.”

After a three-and-a-half-year hiatus, the API Inspection and Mechanical Integrity Summit finally returned in August. Held in San Antonio, Texas, there were nearly 300 technical sessions covering the upstream, midstream, and downstream sectors.

Earlier this year, Inspectioneering and Pinnacle co-hosted their 9th “Meeting of the Minds” roundtable discussion with a select group of leading MI experts. This year's focus was on data collection, data organization, and data analysis.

An informative discussion with David Osage, President and Principal Engineer at The Equity Engineering Group, regarding the recent update to API 579/FFS-1, Fitness-for-Service, and why it's important to our industry.

Inspectioneering and Pinnacle co-hosted the 8th bi-annual Meeting of the Minds with a select group of mechanical integrity experts from across the industry. The meeting focused on major projects in equipment integrity and reliability.

Inspectioneering and Pinnacle co-hosted the 7th bi-annual Meeting of the Minds with a select group of mechanical integrity experts from across the industry. The meeting focused on piping RBI and the challenges operators are facing implementing it.

Inspectioneering and Pinnacle co-hosted their 6th bi-annual Meeting of the Minds roundtable discussion earlier this year. This meeting’s focus was on how Covid-19 and the decline in oil prices have affected MI programs across the industry.

Inspectioneering and PinnacleART co-hosted their 5th Meeting of the Minds roundtable last November in Atlanta. This meeting’s focus was on notable technologies and how they are changing the MI landscape.

At the end of every year, the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) releases its annual list of the 10 most frequently cited safety and health violations for the fiscal year. Although the list rarely sees...

At the end of every year, the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) releases its annual list of the 10 most frequently cited safety and health violations for the fiscal year. Although the list rarely sees substantial changes, it is important for employers to recognize these common violations and implement the necessary procedures to protect their employees.

Last November in Dallas, TX, Inspectioneering and PinnacleART hosted a select group of leading industry experts in mechanical integrity for an informal discussion of some of the key challenges facing the industry today. The main theme for this...

The U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) has released its annual list of the 10 most frequently cited safety and health violations. In 2017 Fall Protection, Hazard Communication, and Scaffolding once again tops the list.

The U.S. Occupational Safety and Health Administration (OSHA) recently released a new guide to help petroleum refiners comply with its Process Safety Management (PSM) standard (1910.119). The guide presents lessons learned from the petroleum...

Inspectioneering recently had the opportunity to sit down and chat with Cary Forgeron and Samuel Fisher about the importance of oil analysis to effectively managing the reliability of rotating equipment used in the the O&G and other processing...

ExxonMobil's "Growing the Gulf" expansion program, consists of 11 major chemical, refining, lubricant and liquefied natural gas projects at proposed new and existing facilities along the Texas and Louisiana coasts.

In 2017 we are adding several new members to Inspectioneering’s Editorial Board. This team of industry subject matter experts will guide the direction of the Journal and other Inspectioneering resources for years to come.

At the end of every year, the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) releases a list of the 10 most frequently cited safety and health violations for the fiscal year, comprised from approximately 32,000 workplace inspections by federal OSHA staff.

Here are five common misconceptions about RBI that should not prevent you from gaining a more advanced understanding of the true state of your site's equipment. After all, the more we know, the better we can manage equipment integrity and make run/inspect/modify/repair/replace decisions.

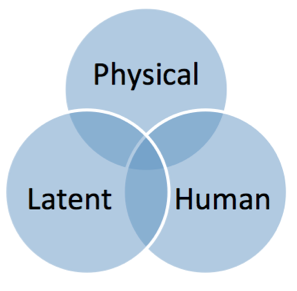

Inspectioneering recently had the opportunity to chat with Jim Weynand, Chief Revenue Officer for Check-6, a global leader in accelerating human performance. Our discussion focused on the effect human factors have on plant operations and how...

Inspectioneering recently had the opportunity to chat with Kent Cheese, Vice President of Marketing and Sales for Bureau Veritas, a global leader in testing, certification and inspection. Mr. Cheese has more than 20 years of experience working...

Inspectioneering recently had an opportunity to sit down with Walt Sanford, President and COO of Pinnacle Advanced Reliability Technologies, and discuss what Reliability means to his clients and others in our industry. We hope you find the exchange interesting and informative.

Inspectioneering recently had the opportunity to chat with Barney Smith, Turnaround Manager at Aggreko, a global leader in power, heating, cooling, and oil-free compressor rental solutions. Our discussion focused on catalyst cooling during hydrocarbon processing and how owner-operators can potentially improve their process.

We at Inspectioneering would like to take this opportunity to thank all of our subscribers, followers, clients, and industry partners for a great 2015, and wish every member of the Inspectioneering community a happy and healthy 2016!

Inspectioneering recently had the opportunity to sit down and chat with Brian Fahnestock about heat exchanger issues in the refining and petrochemical sectors and how temporary solutions can help mitigate the damage should a problem arise.

Inspectioneering recently had the opportunity to sit down with Texas Railroad Commissioner Ryan Sitton and discuss the evolution of reliability in the oil and gas industry.

Inspectioneering speaks with Tom Redlinger about QA/QC practices in the O&G business and what companies can do to create programs that are both effective and sustainable.

There are a number of important stories affecting the Oil & Gas industry right now, but one that hits particularly close to home is the standoff between the United Steelworkers (USW) union and several major oil refiners in the United States. As of February 12, this standoff and simultaneous strike are now in their 12th day, resulting in the largest work stoppage by refinery workers in the United States since 1980.

Inspectioneering recently had the opportunity to sit down and chat with Ray Konet, the Fixed Equipment Reliability Director at Valero Energy, and who also happens to be the Chairman of the Planning Committee for the 2015 API Inspection Summit.

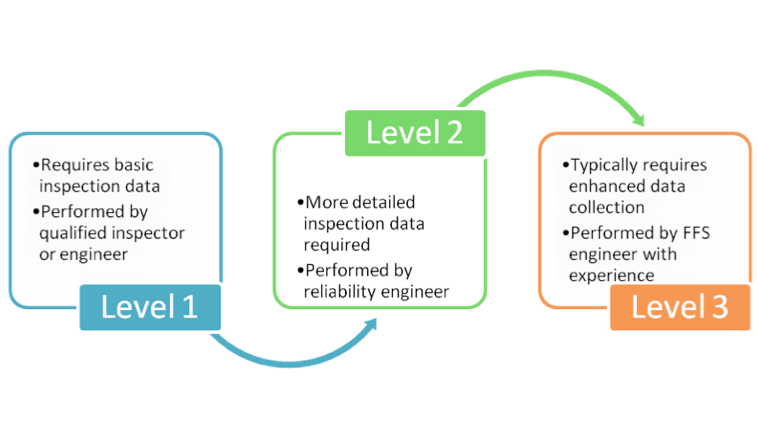

There are numerous benefits to adding fitness-for-service (FFS) assessments to energy sector reliability projects. The acceptance of API 579/ASME FFS-1 is increasing across the energy sector and other industries, as these benefits have been demonstrated in a wide range of projects.

Service failures and safety incidents of machines, structures, and pressure equipment have been experienced in the oil and gas industry for many years without warning, with varying degrees of consequential damages to health, safety, environmental, business, and reputation.

The Province of Alberta has a long history of pressure equipment safety dating back to 1897 when the first boiler laws were introduced to regulate the new technology of steam boilers. Boiler inspectors were hired, and soon thereafter the Alberta Boilers Branch was established as the government organization that administered those laws.

The following interview with Rich Roberts provides answers to some of the questions our readers have about small, specially designed pigs carrying NDE technologies that can inspect nearly every area of a tube from the coils interior surface.

Inspectioneering is pleased to announce that our friend, colleague, author and industry leader, Clay White, has recently taken over as chair of API’s Subcommittee on Inspection (SCI).

Last week we mentioned three important tips to consider when addressing high temperature hydrogen attack (HTHA). This week, we'd like to provide the reader with a few helpful resources that deal with the topic of HTHA.

One of Inspectioneering's editorial themes this month is High Temperature Hydrogen Attack (HTHA). It is a highly contentious issue that the industry is still struggling to fully understand.

Earlier this year, our friends at Pinnacle Asset Integrity Services hosted a webinar entitled Mechanical Integrity Assessment: Why Bother? The broadcast included discussions on the history and value of asset integrity programs, as well as the evolution of the processes and methods necessary to ensure these programs achieve the objective of decreasing risk to improve safety. We have selected a small sample of these exchanges to present to you because we feel they provide important information regarding the need for mechanical integrity assessments in our industry.

I joined Inspectorate in 1988 as Vice President of Gulf Coast Operations in the Oil and Petrochemical Division. I held that role until 1995 when I was appointed Vice President of U.S. operations.

Leak related problems in bolted assemblies are an ongoing issue for virtually all facilities in the chemical, petrochemical, and refining industries. From leak detection to leak prevention, operators need knowledgeable and experienced technicians to address these issues before they become a serious problem. Recently, our friend and media partner, Inspectioneering Journal (IJ), sat down with Dave Godfrey of INTEGRA Technologies to see how INTEGRA is addressing these challenges.