This post is based on an article from the January/February 2013 issue of Inspectioneering Journal by Devon Brendecke, P.E. at Quest Integrity Group. You can find the original article here.

There are numerous benefits to adding fitness-for-service (FFS) assessments to energy sector reliability projects. The acceptance of API 579/ASME FFS-1 is increasing across the energy sector and other industries, as these benefits have been demonstrated in a wide range of projects. The functionality of fitness-for-service makes the methods applicable to many components for a wide range of damage mechanisms. If a maintenance program does not already include fitness-for-service assessment capabilities, the preparation required to perform FFS assessments may mean the delay of putting a critical asset back into service on schedule.

Basic Fitness-for-Service Program

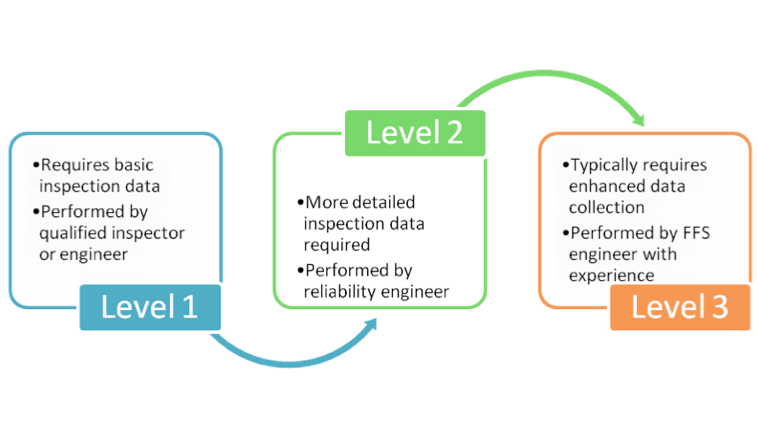

FFS assessments usually require a standard list of information including original design conditions, materials of construction, and operation and maintenance history. While this information is part of standard record keeping at many facilities, it is not always readily available. There are three levels of assessment, all of which are progressive:

Level 1

Level 1 assessments require the least amount of data and experience. This type of assessment usually uses tables and screening curves and requires few computations. This means the computations can be quite conservative, similar to design code calculations. This level of inspection tends to take less time than the other two.

Level 2

If a Level 1 assessment on a piece of equipment does not meet acceptance criteria, a Level 2 assessment can be performed. A Level 2 assessment requires significantly more involved computations to replace the simple, conservative computations that make up the Level 1 assessment. The benefit is that fewer conservative calculations may lead to a better outcome, but the computations are complex enough that FFS software is often required.

Level 3

Generally, Level 2 assessment criteria are met and the equipment can be returned to service. But, In severe cases, a Level 3 assessment may be required. Compared to the previous two levels, a Level 3 assessment requires more detailed data and a considerable amount of operational experience on the part of the inspector. Because of errors that can occur due to using the more advanced equipment Level 3 analysis are rarely conducted.

The factors that go into selecting a level of FFS include the quantity of data available with which to perform an evaluation, the quality of that data, and the degree of significance of the analysis to equipment operations.

Conclusion

Instituting an FFS program as part of a reliability management program helps reduce challenges related to budget acquisition and assessment completion time. Preparing for potential assessment before a shutdown can save time collecting the data required to complete the assessment.

Including fitness-for-service technology and assessment capabilities as part of regular maintenance programs can save time and costs during critical outages. Ensuring that these capabilities exist as part of a maintenance program budget can prevent the extension of shutdowns and potentially avoid unplanned shutdowns.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.