Mark Geisenhoff: About the Author

Global Fixed Equipment Leader, Flint Hills Resources

Mark Geisenhoff is the Global Fixed Equipment Leader for Flint Hills Resources within the Operations Services Group. Mark’s 40 years of experience has focused on mechanical integrity and fixed equipment reliability and inspection practices. He has led reliability and mechanical integrity groups at various sites and has been in the corporate leadership position since 2008. Mark is an active member within API and AFPM and is the current vice-chairman of API Sub-Committee on Inspection & Mechanical Integrity (SCIMI) and chairman of the Advancing Process Safety MI Subgroup (MISG).

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

Temporarily or permanently installed thickness monitors can help to overcome shortcomings and uncertainties associated with manual ultrasonic inspections and can lead to significantly improved maintenance and asset replacement forecasting.

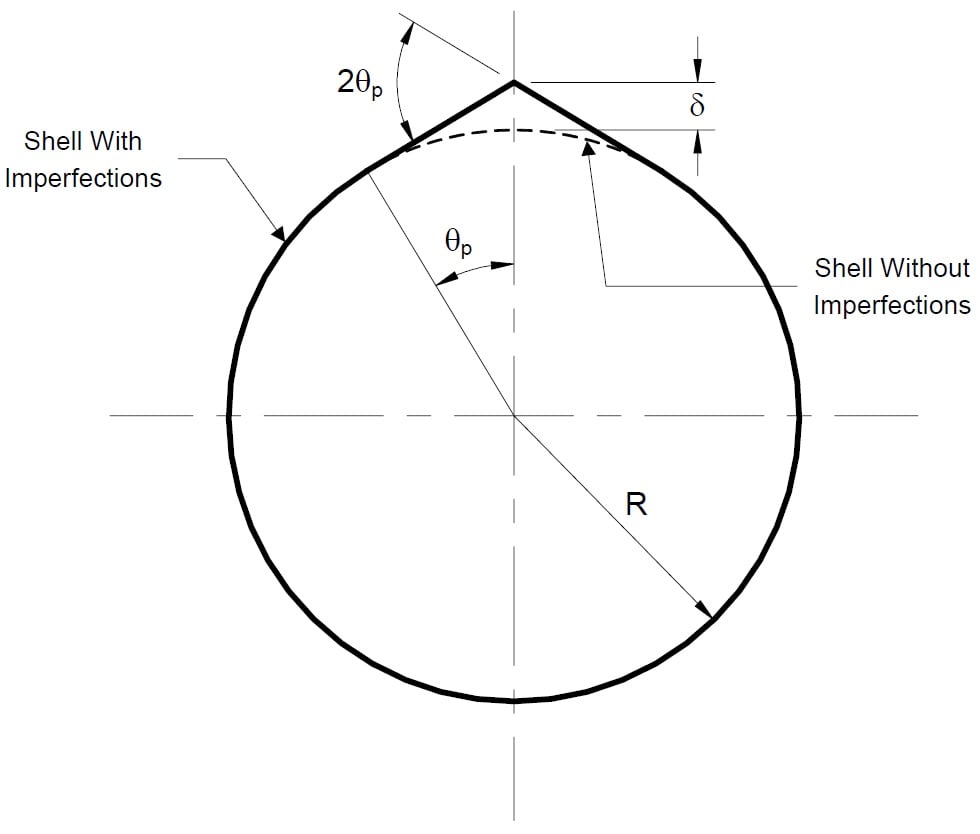

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.

Risk-Based Inspection (RBI) is an emerging technology available to plant engineers and managers as theyapply risk directed activities to prioritize work and available resources for equipment management. This paper describes the learning of highly experienced RBI users, sharing results of implementation in their plants. The advantages of making and documenting reasonable assumptions will be explored.

Risk Based Inspection (RBI) analysis is a powerful tool that all of us can use to help with the complex issues of risk. The opportunities for application are exciting and open the door for new ways of conducting business and focusing resources. Along with these new and exciting opportunities comes the responsibility for all of us to apply RBI in a responsible manner.

Risk-Based Inspection (RBI) is an emerging technology available to plant engineers and managers as they apply risk directed activities to prioritize work and available resources for equipment management. This paper describes the learning of highly experienced RBI users, sharing results of implementation in their plants. The advantages of making and documenting reasonable assumptions will be explored. Additional benefits of the program will be shared, such as streamlined process reliability studies where RBI information can significantly impact time required for completion. Results of using the API RBI methodology for storage tank analyses will also be presented. The presenters have a combined refinery experience of over 40 years and RBI experience of over 10 years with responsibility for over 20,000 pressure vessels and overall responsibility for equipment integrity in two large refineries.