Phillip E. Prueter: About the Author

Principal Engineer II and Senior Vice President of Consulting, The Equity Engineering Group, Inc.

Phillip E. Prueter, P.E. is a Principal Engineer II and Senior Vice President of Consulting at The Equity Engineering Group, Inc., where his responsibilities include leading Consulting Services with a focus on providing technical engineering support. He specializes in fitness-for-service, design by analysis, explicit dynamics, thermal-mechanical fatigue analysis, elevated temperature creep, seismic and natural frequency analysis, fracture mechanics, root-cause failure analysis, damage mechanism reviews, and high-temperature hydrogen attack. Additionally, he is a member of the ASME Working Groups on Design by Analysis and Elevated Temperature Design and has authored or co-authored more than 50 technical publications.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

An overview of the types of in-service metallurgical embrittlement and other conditions that can accelerate embrittlement and increase the risk of cracking.

The final installment of the series concludes by providing practical insight into common brittle fracture and ductile tearing mitigation strategies.

Part 2 of this three-part series on brittle fracture focuses on methods for evaluating the risk in pressure equipment and the evolution of screening and assessment methods.

This article is Part 1 of a new three-part series on brittle fracture and focuses on the fundamental concepts and damage morphology associated with the unstable rupture of pressure equipment.

Part 3 of this series focuses on practical damage mitigation and life cycle management techniques to avoid failures and corrosion in refinery pressure equipment.

This installment of Damage Control outlines the FFS methods available to analysts for evaluating wall loss such as sulfidation or high-temperature H2/H2S corrosion in pressure equipment

Comprehension of the sulfidation corrosion reaction and the behavior of different materials in H2-free and H2/H2S environments is imperative for oil refineries.

Part 3 of this series provides pragmatic strategies for mitigating high-temperature creep damage in typical pressure component alloys.

Part 2 of this Damage Control series on high-temperature creep discusses engineering evaluation methods that can be used to predict the remaining creep life of components. Comparisons between the Larson-Miller Parameter and the MPC Omega are offered.

A focus on typical damage morphology and inspection methods used to identify and characterize high-temperature creep including examples of creep damage and in-service failures to offer insight into this complex damage mechanism.

This final installment of a 3-part series on SCC mitigation will provide practical, actionable steps to improve long-term equipment reliability through design, fabrication/welding, heat treatment, maintenance/repair, and process operating practices.

Part 2 of the three-part series on stress corrosion cracking (SCC) that examines common engineering and FFS methods that can be leveraged to understand and evaluate the propensity for an existing form of SCC to lead to loss of containment.

This article provides an overview of some of the more common forms of stress corrosion cracking (SCC) with a focus on effective inspection methods for detecting these forms of cracking.

This edition of Damage Control will offer practical steps to mitigate different forms of wet H2S damage and help to minimize long-term inspection and maintenance costs related to wet H2S damage.

This issue of Damage Control offers a perspective on how to assess the different forms of wet H2S damage using modern FFS and computational analysis techniques with the safe operation of damaged pressure vessels, piping, and associated components.

This article summarizes the fundamentals of wet H2S-related damage mechanisms, offers some practical inspection guidance, and reviews a notable industry failure caused by different forms of wet H2S damage.

Practical steps to mitigate corrosion under insulation (CUI) damage on fixed pressure equipment and commentary on common mitigation techniques and good engineering practices for external insulation or fireproofing system design and application.

In this article, FFS assessment methods are summarized and practical guidance is offered for qualifying CUI damage on carbon and low-alloy steels.

Corrosion under insulation is a form of external corrosion that is caused by trapped water on insulated surfaces. It is an industry problem affecting equipment in the oil and gas, petrochemical, specialty chemical, fertilizer, and related industries.

Thermal fatigue, a specific form of fatigue driven by varying metal temperature gradients and ensuing differential thermal expansion, is generally most effectively mitigated by reducing the severity of metal temperature gradients.

Conventionally, three primary fatigue analysis methods have been used to estimate fatigue life; these are the stress-life (S-N) approach, the strain-life (ε-N) approach, and the fracture mechanics (crack growth) approach.

This article reflects the first in a series on damage mechanisms that will appear in this recurring Inspectioneering column entitled “Damage Control.” The inaugural topic discussed in this column is thermal fatigue.

This article provides an overview of brittle fracture, details on several industry failures, and a summary of deficiencies and concerns with current published methods for screening susceptibility of equipment to potential brittle fracture failures.

Given the concern throughout industry regarding the potential for brittle fracture failures, PWHT guidance to address potential issues arising from the recent changes in PWHT code requirements for carbon steel is examined in this article, and commentary on the potential reduction in fracture toughness due to PWHT is provided based on a review of published literature.

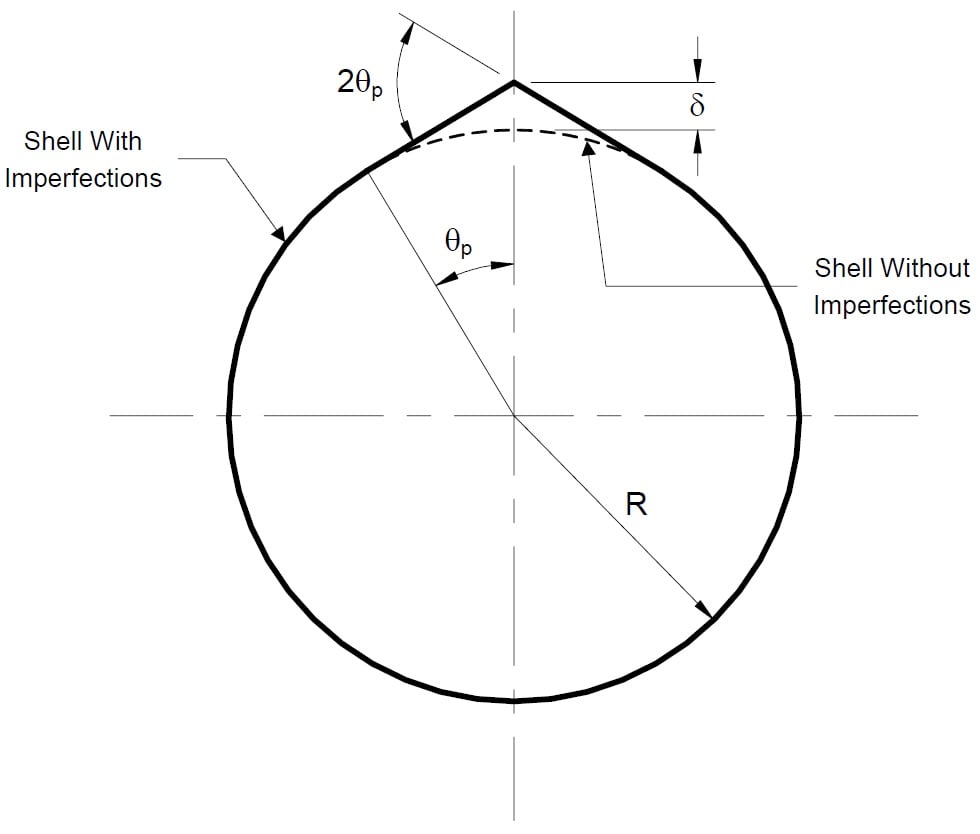

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.