Brittle Fracture is the sudden, very rapid cracking of equipment under stress where the material exhibited little or no evidence of ductility or plastic degradation before the fracture occurs. Unlike most other tensile failures, where the material plastically strains under overload conditions and becomes thinner until the point of rupture, when a piece of equipment suffers a brittle fracture, there is no thinning or necking down. Rather, this damage mechanism often causes cracking without warning, sometimes fracturing equipment into many pieces.

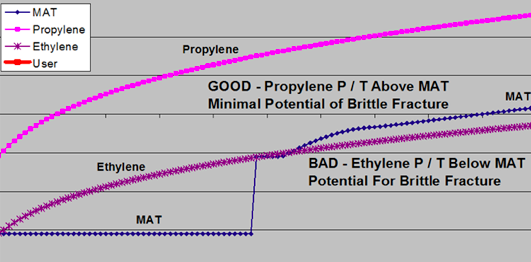

Brittle fracture is often caused by low temperatures. If the steel temperature is at or below its ductile-to-brittle transition temperature (DBTT), then it will be susceptible to brittle fracture. Combine this with a critical sized flaw and high stress on that flaw (either applied or residual), and then you are likely to experience a brittle fracture.

Other factors that can increase the susceptibility to brittle fracture include:

Metallurgical Degradation

Metallurgical degradation can occur in some steels at higher temperatures and can include things like temper embrittlement, graphitization, sigma phase embrittlement, and 885 embrittlement.

Steel Cleanliness and Grain Structure

As for steel cleanliness and grain structure, large grain sizes and steel contaminants can reduce steel toughness, so it's important to be aware and mindful of this during material selection amd QA/QC.

High Material Thickness

When it comes to material thickness, thicker components have a higher degree of susceptibility to brittle fracture because they have higher tri-axial stresses. Also, thicker materials produce a state of higher constraint, and are therefore less likely to deform under stress as opposed to crack initiation and propagation.

Colder Operating Temperatures

Operating an equipment or piping at temperatures colder than its lower design temperature (LDT, also known as Minimum Design Metal Temperature or MDMT in ASME codes) at sufficient operating pressure can also cause brittle fracture. Hence it is always important to operate an equipment/piping within its design limits. API RP 579 part-3, "Assessment of Existing Equipment for Brittle Fracture" provides guidelines to check if an equipment can be operated at temperatures colder than LDT, without brittle fracture damage to the equipment.

Types of Brittle Fracture

There are two major types of brittle fractures: transgranular and intergranular. With transgranular fractures, the fracture travels through the grain of the material. It changes direction from grain to grain due to the different lattice orientation of atoms in each grain, following the path of least resistance. Intergranular fracture, on the other hand, occurs when the a crack travels along the grain boundaries, as opposed to through the grains themselves. Intergranular fracture usually occurs when the phase in the grain boundary is weak and brittle.

Brittle Fracture Prevention/Mitigation

In order to reduce the risk of brittle fracture, one must be sure to keep materials operating at or above their DBTT during both service and testing. Likewise while conducting repairs, taking steps to establish and find flaws that might weaken the material while in-service or during pressure testing will reduce the chances of brittle fracture. This topic is covered in more detail in API RP 571 - Damage Mechanisms Affecting Fixed Equipment in the Refining Industry.

Related Topics

- Carburization

- Cavitation

- CO2 Corrosion

- Cooling Water Corrosion

- Corrosion Fatigue

- Corrosion Under Insulation (CUI)

- Cracking

- Decarburization

- Embrittlement

- Erosion Corrosion

- Fatigue (Material)

- Flue Gas Dew Point Corrosion

- Graphitization

- Green Rot

- High Temperature Hydrogen Attack (HTHA)

- High-Temperature Creep

- Hydrochloric (HCl) Acid Corrosion

- Hydrofluoric (HF) Acid Corrosion

- Hydrogen Embrittlement

- Hydrogen Stress Cracking

- Liquid Metal Embrittlement (LME)

- Metal Dusting

- Microbiologically Influenced Corrosion (MIC)

- Naphthenic Acid Corrosion (NAC)

- Phosphoric Acid Corrosion

- Pitting Corrosion

- Spheroidization (Softening)

- Stress Assisted Corrosion

- Sulfidation Corrosion

- Sulfuric Acid Corrosion

- Thermal Fatigue

- Vibration-Induced Fatigue

- Wet H2S Damage

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition