High Temperature Hydrogen Attack (HTHA) is an insidious condition that can occur in process equipment exposed to hydrogen at elevated temperatures (at least 400F or 204C), under dry conditions, when hydrogen disassociates into nascent (atomic) hydrogen, which is then driven into the steel by the temperature and pressure of the environment. The atomic hydrogen then reacts with unstable carbides in steel to form methane gas, which accumulates in the microstructural grain boundaries, eventually leading to cracking. This is often hazardous as the equipment usually contains hydrocarbons at high pressures and temperatures.

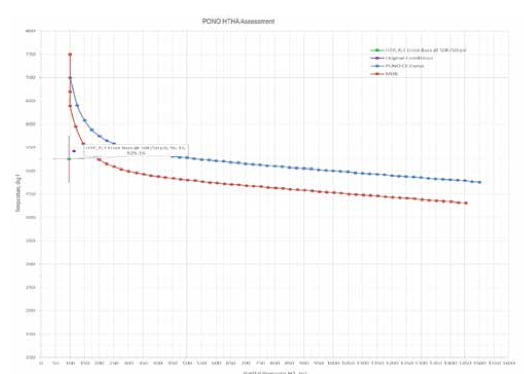

HTHA is a time-temperature-pressure dependent phenomenon. This means the longer that a piece of equipment is exposed to temperatures and hydrogen partial pressures above its resistance limit, the more damage to the steel will accumulate; and the higher the temperature rises above the limit of the steel, the more rapidly the damage will occur.

FREE RESOURCE: Click here to download a more detailed overview of HTHA.

Susceptible Areas

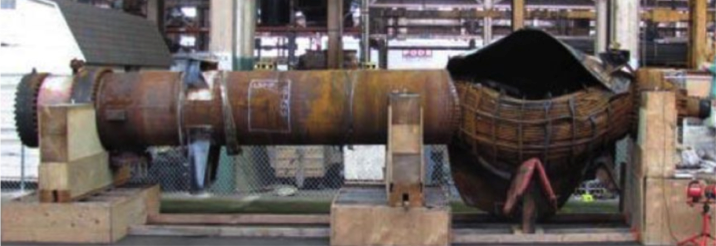

HTHA affects carbon and low alloy steels, but is most commonly found in carbon steel and carbon-1/2 Mo steel that is operating above its corresponding Nelson Curve limits. Areas that are hotter, often near the outlet nozzle of catalytic equipment or the inlet nozzle of an exchanger that is cooling the process, are areas of concern for HTHA. Welds often suffer from HTHA degradation as well.

Prevention/Mitigation

Typically HTHA can be avoided by choosing the proper alloy steel or stainless steel cladding to resist the combination of hydrogen partial pressure and temperature, or by adjusting the operating conditions to stay below the Nelson Curve limit for the existing materials of construction. However, there have been several cases where HTHA was found even though operating conditions were below the Nelson Curve.

Inspection Techniques

It can often be difficult to predict the specific areas to inspect for HTHA, since the damage can be very localized. A corrosion or materials specialist, experienced in this particular phenomenon, should be consulted for identifying susceptible equipment, selecting inspection locations, and estimating remaining life of equipment in this service.

Inspection techniques for finding advanced stages of HTHA at the surface include WFMT, MT, and in-situ metallography (e.g., field metallographic replication). Advanced ultrasonic backscatter testing (AUBT) has also been successfully used to find earlier stages of HTHA.

References

Related Topics

- Brittle Fracture

- Carburization

- Cavitation

- CO2 Corrosion

- Cooling Water Corrosion

- Corrosion Fatigue

- Corrosion Under Insulation (CUI)

- Cracking

- Decarburization

- Embrittlement

- Erosion Corrosion

- Fatigue (Material)

- Flue Gas Dew Point Corrosion

- Graphitization

- Green Rot

- High-Temperature Creep

- Hydrochloric (HCl) Acid Corrosion

- Hydrofluoric (HF) Acid Corrosion

- Hydrogen Embrittlement

- Hydrogen Stress Cracking

- Liquid Metal Embrittlement (LME)

- Metal Dusting

- Microbiologically Influenced Corrosion (MIC)

- Naphthenic Acid Corrosion (NAC)

- Phosphoric Acid Corrosion

- Pitting Corrosion

- Spheroidization (Softening)

- Stress Assisted Corrosion

- Sulfidation Corrosion

- Sulfuric Acid Corrosion

- Thermal Fatigue

- Vibration-Induced Fatigue

- Wet H2S Damage

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition