High Temperature Hydrogen Attack (HTHA) is a long known and still occurring degradation issue for fixed equipment construction materials in the hydrocarbon process industry where hydroprocess plants (hydrogen plus hydrocarbons) are in service. Though HTHA failures in these units are the focus of this article, it is important to recognize that HTHA damage can also occur in high pressure boiler tubes, hydrogen producing units, synthetic gas units, ammonia plants and other equipment where hydrocarbons may not be involved but high temperatures are involved. And as the title implies this article focuses on existing equipment in process plants which may have some HTHA issues generally not considered or associated with specifying new equipment.

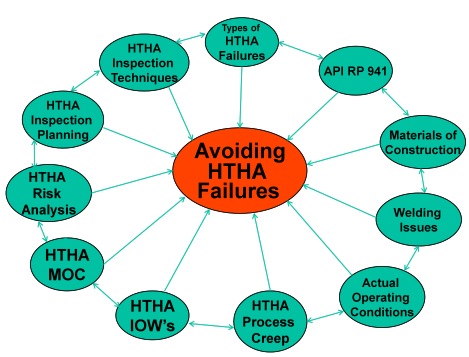

Major failures from HTHA are not very common, but they do happen, sometimes with enormous safety and economic consequences because the incidents involve high pressure and high temperature releases of hydroprocess fluids. This article will outline how to avoid HTHA failures in existing equipment, by understanding the interaction of numerous HTHA factors, understanding and applying the latest edition of API RP 941(1), establishing and implementing Integrity Operating Windows (IOW’s)(2), monitoring and controlling operating conditions that might lead to HTHA, applying risk assessment techniques to HTHA susceptible equipment, and doing adequate inspection planning for HTHA. Figure 1 is a more complete visual outline of the HTHA issues that will be covered in this article, showing the “spider web” interaction between all the issues required to avoid HTHA failures.

There’s an old safety saying that goes something like: “What you don’t know can kill you”, and it is surely true when it comes to HTHA. Though this brief article will not tell you everything you might need to know about HTHA in existing equipment, it will provide an overview of how to go about avoiding and detecting HTHA and guide you to other resources from which you can continue to learn more.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.