7 Questions You Need to Answer when Establishing an Integrity Management Program

Advancements in CUI Detection and Overview of MsS Guided Wave

Calculating the Required Structural Thickness of Pipe Using Beam Stress Theory

CML Reduction – Are you planning to fail?

Dead Leg Integrity Management System

Proper Assessment of Inspection Findings

RBI, Inspection Effectiveness and Human Factors

Choosing the Right Smart Pigging Technology – Lessons Learned

Detecting and Quantifying Cracks Using Eddy Current Array

Integrating and Planning Maintenance Activities in Oil and Gas Installations

Remote Integrity Monitoring of High Criticality Equipment in Real Time

Supplier Technical Assessments

The Hierarchy of a Fixed Equipment Asset Integrity Management Program

Achieving Excellence in PRD Integrity Management

Auto-Ignition of Ultrasonic Couplants During Thickness Gauging and Corrosion Mapping

Common Sense Maintenance Front Line Supervisor Development and Utilization – Part 2

Digital Radiography of Welds Using Flat Panel Detector Base Image Sensors

Embracing a New Approach to Retroactive PMI

Pipeline Failure – Safeguards Are so Important to Hydrocarbon Transport Lines

RBI – Real-Time Turnaround Management

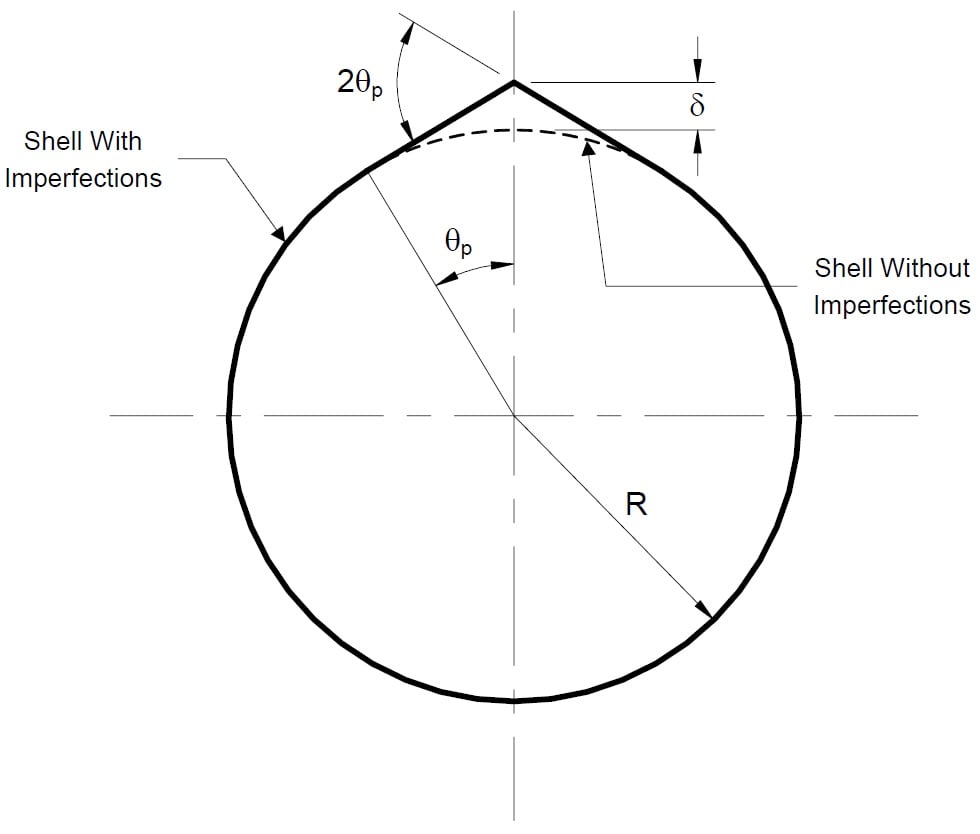

Remaining Life Sensitivity to Longitudinal Weld Seam Peaking in High-temperature Low Chrome Piping

Clearing out the Data Clutter: How well-maintained data can add value to your reliability program

Common Joint Integrity Challenges on CAPEX Projects

Highlights from API’s 2016 Spring Refining Standards Meeting: Subcommittee on Inspection (SCI)

Improving Confidence in On-Stream Inspections of Pressure Equipment

Powering Impressed Current Cathodic Protection — Part 2

The Application of Response Surface Methodology in Modeling Corrosion Rates

The Profit Motive: Process Safety Management, Loss of Containment and Lost Profit Opportunity

The Use of Miniature Test Specimens in Fitness-for-Service Evaluation

Advanced NDT for Plant Life Assessment

Creating an Effective Inspection Recommendation Management System

Fired Heater Health Monitoring and Reliability Management in Challenging Times

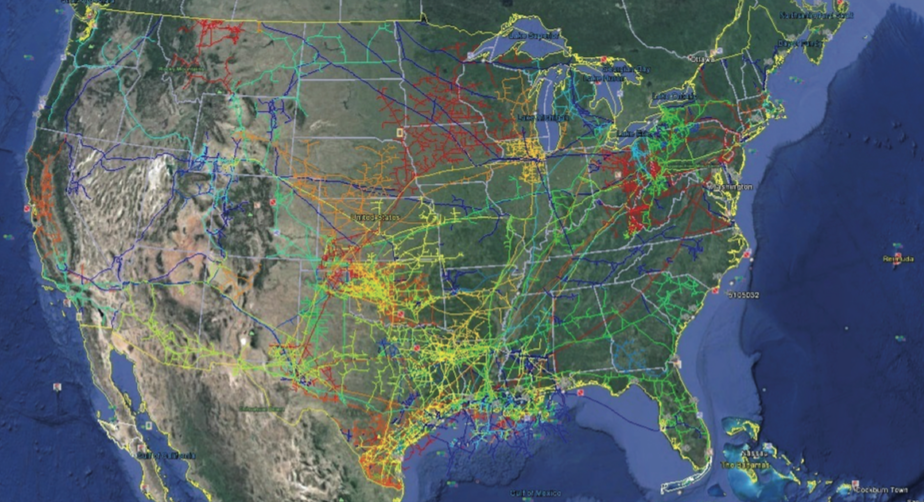

Standardized Pipeline Risk Comparison and Prediction

Ultrasonic Phased Array Tools for High-Resolution Corrosion Inspection

Ultrasonic Sensor System for Wall-Thickness Monitoring

2015 is behind us – Let’s Look Ahead

Advanced Pipeline Management Software Can Reduce Risks and Improve your Bottom Line

Common Sense Maintenance Front Line Supervisor Development and Utilization – Part 1

Effectively and Efficiently Cleaning Heat Exchangers — Part 3

Inspect Yourself into Outstanding Performance

Maintenance Strategies for Aboveground Storage Tanks in Crude Oil Service — Part 2

My Inspection App Can Do What?

On-Stream Thickness Monitoring Versus Conventional Inspection in Refineries

2016 Inspectioneering Journal Article Index

The enormous decline in oil prices over the past 14 months has definitely slowed projects and changed the energy and production landscape. Despite this, refineries, petrochemical plants, and chemical facilities must continue to run safely,...

This article summarizes seven key questions that an organization needs to answer to create a robust mechanical integrity program that is properly designed to monitor corrosion and indicate when issues increase to a level requiring review or...

Many plants inspect PRDs on preset intervals as recommended by inspection code API 510, and implement inspection practices such as API RP 576. Just seeking PRD compliance with codes and standards usually results in mediocre mechanical integrity and...

While there are many types of advanced NDT, this article will focus on the use of acoustics and electromagnetism as the bases for conducting examinations.

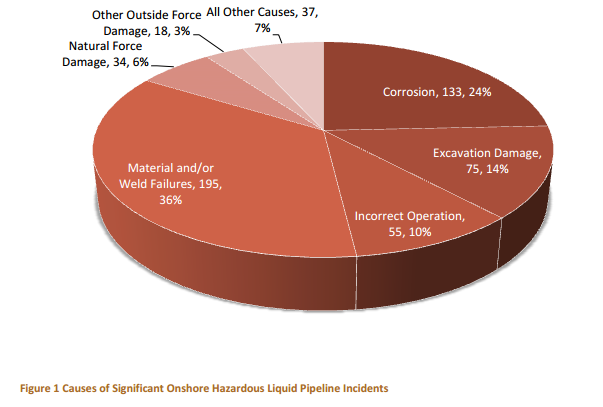

Pipeline management remains fraught with safety risks for operators and the environment. Last year, the Ontario Energy Board determined that a $12 billion oil pipeline proposed by TransCanada Corp. would pose more risks than rewards for the province.

Beyond the financial hits, undetected degradation from corrosion can also lead to critical safety risks. To effectively manage mechanical integrity, organizations need reliable methods of identifying the current states of corrosion occurring within...

In numerous industries that require elemental and material testing, including the oil and gas, power generation, and petrochemical industries, positive material identification (PMI) is at the forefront of any operation. In fact, an increasing number...

This article details the basis for the lack of understanding about the potential for ultrasonic couplant auto-ignition and outlines an ALARP operating practice for mitigation.

This article will go through the methodology of each process that could be used in determining the structural component for the required pipe wall thickness, but will focus on the use of Beam Flexural Stress calculations and Beam Deflection...

Although all ultrasonic smart pigging providers claim the ability to detect wall thinning and tube deformations to some degree, the inspection surface coverage, resolution, minimum wall thickness detection and reporting capabilities may vary...

Traditional, paper-based inspection processes can prevent plants from being as effective as they can be. By digitalizing your mechanical integrity process and data with MISTRAS Digital®, plants have realized up to 75% gains in IDMS data entry and...

Data, in pure form, consists of raw, unorganized facts that need to be processed. Data can be found in databases, documents, drawings, reports, spreadsheets, and numerous other sources. Having data on hand is useful, however, it’s often...

The concept of reducing Condition Monitoring Locations (CMLs) is misguided, and the number and location of CMLs should be OPTIMIZED, not systematically reduced. CML allocation in piping requires a good process, otherwise, you can run into a lot of...

Large scale capital projects present a myriad of challenges for owner-users in the oil and gas and petrochemical industries. Budgets are constantly being stretched and project deadlines are often exceeded. One area that deserves attention from all...

It is a generally accepted fact that most Front Line Supervisors (FLS) come up “from the ranks” of the hourly staff. However, most companies provide neither training nor any type of preparation or guidance for the person they have now placed...

This article will examine what can occur during the course of a Front Line Supervisor’s day that may hinder the execution of their expected duties, and what can be put in place to overcome those obstacles.

We have seen many different inspection recommendation management systems. Most of them struggle to effectively manage all inspection recommendations. However, a few of them are excellent. What makes an effective system?

This article describes a high-level dead leg integrity management program overview and is based on experience, knowledge, and adaptation of inspection management philosophies currently being implemented within the Oil & Gas and the petrochemical...

Detecting, quantifying, and sizing indications characterized as a “crack" in critical equipment have long been the global benchmark of asset integrity programs. Therefore, the increased precision that inspection programs obtain using advanced...

In the last few years, electromagnetic acoustic transducer (EMAT) has come to prominence for its ability to quickly scan exposed pipelines for corrosion, cracks, and other defects using medium-range guided waves and without the requirement for...

The structural integrity of components is controlled by material properties, the presence of flaws, and levels of applied stress. Several factors such as temperature, type of loading, toughness, corrosion resistance, micro-structural stability, cost...

Heat exchangers operating in refineries or petrochemical plants must be thoroughly cleaned and inspected throughout their operational lifetime to ensure safe and efficient operations.

The instrumentation available to detect inadvertent material substitutions through positive material identification (PMI) has never been more available, portable or powerful than it is today. For one industrial services company, Tacten Industrial,...

This paper provides the background for the technology behind the Third Edition thinning model as well as step-by-step worked examples demonstrating the methodology for thinning in this new edition of API RP 581.

The problem is, you don’t. With the out of date procedures that traditional inspection contractors use, data is usually invalid by the time it reaches your system. You rely on this data to make critical decisions regarding integrity concerns, and...

Achieving fired heater reliability in conjunction with meeting performance standards can be a challenging feat. Performance is a measure of the degree to which the fired heater is in an operable condition at any given time.

This brief article contains updates and highlights related to the Subcommittee on Inspection (SCI) at the 2016 API Spring Refining Equipment and Standards Meeting.

RBI and NII are designed to achieve significant cost savings and risk mitigation benefits over a piece of equipment’s lifetime in the long term.

When heading down the path of becoming an inspection professional, it’s helpful to understand the characteristics that truly make someone an outstanding inspector.

For all operators, a system made up of a variety of equipment must be available to carry out continued operations. Planning plays a vital role in the success of major maintenance projects. Integrating all departments in the maintenance plan can save...

Equipment integrity and reliability programs are essential for refinery and chemical facility operators. The processes of the programs are developed to ensure safety, optimize component life cycles, and promote smooth and economical operations.

It is estimated that there have been more than 250,000 layoffs in the oil and gas industry since the price of oil began to drop precipitously in late 2014. With oil not expected to rebound significantly for at least the next year or so, we should be...

In Part 1 of this 2-part series, published in the July/August 2015 issue of Inspectioneering Journal, I discussed corrosion control methods and some effective techniques for inspecting ASTs, and also identified several root causes of AST failures in...

You probably already know that inspection apps for tablets and smart phones exist, and have notions of how these technologies can improve efficiencies in the field and beyond.

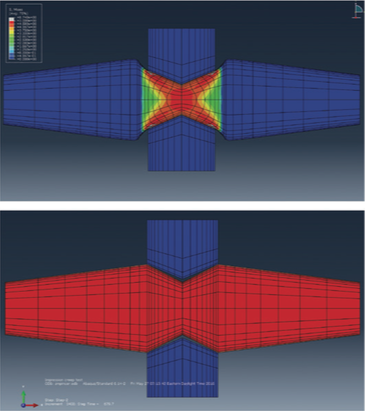

This article exhibits how modern inspection methodologies combined with innovative computational analysis practices demonstrate the value of conducting fitness-for-service (FFS) assessments on sectional piping.

Fixed equipment in a refinery can be susceptible to corrosion from the process side, necessitating an inspection strategy to understand the condition of that equipment. Online measurement of pipe and pressure vessel wall thickness is made possible...

Joint integrity management remains at the top of many operators’ priority list. The discipline considers risk and drives safety to ensure we learn necessary lessons from past catastrophic failures, such as the Piper Alpha explosion in 1988,...

An overview of process piping vibration and evaluating piping systems in vibration service to reduce harmful vibrations.

This is the second article of a two-part series published in Inspectioneering Journal, which is intended to provide a basis for understanding the differences between traditional tapped-transformer, fixed voltage type rectifiers, and High Frequency...

TEAM provides full inline, onsite and, shop valve repair services and maintenance programs for virtually all valve types, brands, sizes, materials, pressures, and operating conditions, including actuators and operators. Our valve repair solution...

Integrity and reliability personnel at processing facilities are no strangers to initiatives to improve processes in the pursuit of establishing best-in-class reliability programs. It is common practice for operators to enlist help from third...

As the industry strives to maintain PSM/OSHA compliance through owner/user mechanical integrity programs, inspection professionals should fully understand technical standards to generate an adequate repair recommendation or request further...

Turnarounds operate at a different pace than routine work. Most plant-based inspection departments have historically struggled with Turnaround document control, such as integrating contractor reports into their routine data management system. Our...

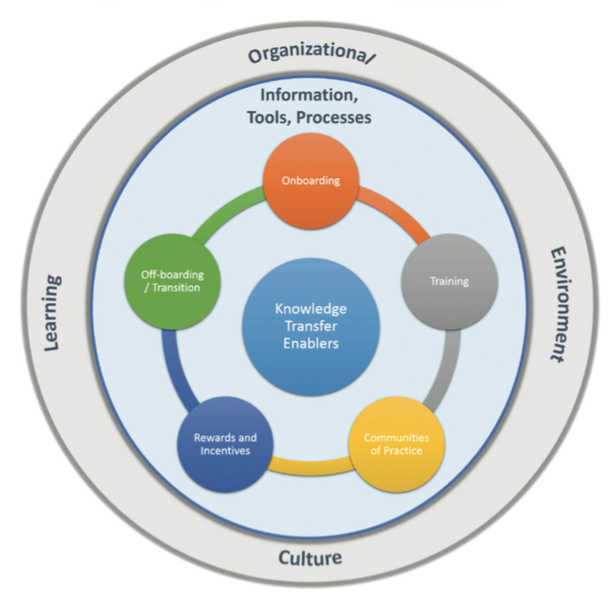

Human factors, inspection effectiveness, and RBI all play an important role in running an effective asset management program. This article discusses how each is applicable to inspecting equipment in processing facilities.

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.

Remote monitoring solutions are making it possible to avoid sending personnel into harsh environments without forgoing the essential data gathering that keeps assets safely operating.

The objective of this article is to demonstrate the inherent value of an interactive and detailed GIS landscape, emphasize the importance of industry standardization, and encourage regulatory agencies and operators to systematize and incorporate...

Having a systematic, proven methodology for effectively qualifying suppliers is extremely important. Supplier Technical Assessments, or “vendor assessments,” help buyers evaluate suppliers’ qualifications when considering their capabilities...

The main intention of this article is to introduce the Response Surface Methodology (RSM) using some of the elements of critical thinking as a guide. This methodology is not often used in the industry, but can be widely used by corrosion/process...

Did you ever wonder where you fit into the entire hierarchy of a fixed equipment asset integrity management (FE-AIM) program? Or who is responsible and accountable for what aspects of FE-AIM at your site? All the way from top management down to...

Risk-based inspection (RBI) programs and processes are front and center, both as a challenge to get it right, and as an integral tool and process to help us achieve success in risk management and equipment reliability. It has to be implemented,...

Whether you decide for a Computed Radiography scanner with flexible imaging plates or a flat panel detector with the fastest imaging, or even combine the advantages of both technologies, DÜRR NDT's innovative systems offer high reliability and...

This paper identifies the attributes and benefits of a data and metrics-driven management system focused on process safety design integrity and reliability relative to loss of primary containment (LOC). This management system process focuses on the...

Aging equipment, along with more aggressive service, makes it more important than ever to carry out fitness-for-service (FFS) assessments in support of run/repair/replace decisions. Testing material in the service-degraded condition enables...

This article highlights the evolution of corrosion monitoring from conventional ultrasonic to ultrasonic phased array manual and automated solutions and their use for both general purposes and complex applications.

While there are many methods for measuring equipment wall thickness, a predominant method used in the O&G and power generation industries is portable ultrasonic equipment. Ultrasonic testing is non-intrusive because it is applied to the outside of a...

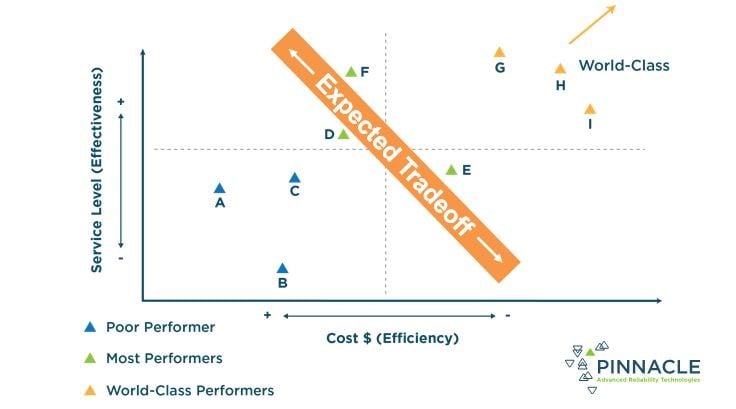

Inspectioneering recently had an opportunity to sit down with Walt Sanford, President and COO of Pinnacle Advanced Reliability Technologies, and discuss what Reliability means to his clients and others in our industry. We hope you find the exchange...

An explanation of refractory including its uses and recent advancements in abrasion-resistant materials, dry-out/cure times, improved installation methods, and anchoring systems.

In the first quarter of 2016, Texas-based DronePro LLC completed the first ever inside-the-derrick inspection of an offshore drilling rig utilizing a proprietary unmanned aircraft system (UAS), or drone, with its associated technology and equipment.