Quality Auditing & Reporting (QAR)

When More Means Less: Increasing Inspection Effectiveness to Reduce Remediation Costs

How to Put it All Together - A Guide to Organizing a Successful PEI Program

Obtaining Leak Free Bolted Joint Operation by Returning to Basics

2009 Inspectioneering Journal Article Index

The ASME Post Construction Committee (PCC) has embarked upon a noble activity to produce a guide to using codes, standards, recommended practices, specifications and guidelines that can be used by manufacturers, owners, users, regulators, engineers...

We have been introduced to Infrared Thermography (IRT) since World War I and over the last decade the application of this technique has gained impetus. Today, the IRT application is widely used and accepted by many industries such as power...

Ultrasonic thickness gages have progressed a long way since their early development in the 1960's. The first thickness gages were large and bulky although they used the same conventional longitudinal (compressional wave) techniques still in use...

This article provides a unique opportunity to guide the reader through API RBI quantitative calculations per API RP 581, Second Edition, September 2008, using real data. The author guides you step by step from input data to final answers including,...

The previous article (Part 1) covered Probability of Failure (POF), including modeling of thinning and stress corrosion cracking and demonstrated how API RBI provides credits for past inspections, considering their effectiveness in detecting those...

This article is Part 3 of a 3-Part series. The articles in this series provide a step-by-step example of utilization of API RP 581 and build off of each other. This article (Part 3) will cover the final risk analysis, inspection planning, provide a...

In the current economic environment, there is increasing pressure on petrochemical refineries and delivery systems to be more productive and to minimize unscheduled shutdowns due to leakage. Leakage can occur from either the piping itself or the...

Knowing what needs to be accomplished in order to achieve excellence in pressure equipment integrity (PEI) is one thing, but knowing how to organize it all for success is quite another.

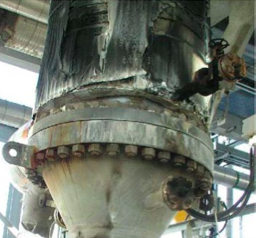

In the oil and gas industry, pressure vessel integrity is a major concern. After internal and external inspections various anomalies or defects can be reported and repairs could be required for pressure vessels in order to restore its original...

History has taught us that we should trust, but verify! Verification of alloys to ensure they are composed of the correct alloying elements has been the realm of handheld x-ray fluorescence for the past four decades. Industries ranging from...

Leakage of pressure vessel and piping bolted joints in refineries is an unnecessary hazard, with high associated cost, that can be easily rectified using currently available technology. There have been advances in gasket testing technology in recent...

Progress has been made in this area over the last 5 to 10 years. Here is a listing of helpful references for managing pipeline integrity that represents a lot of that progress and experience. It is by no means exhaustive. To the best of our...

Learn how you can safeguard integrity, reliability, instrumentation safety, and more.

The market around the globe is being opened up. More and more manufacturers are entering the fray from different parts of the world. The competition is tightening at an unprecedented rate causing considerable reduction in profit margins enjoyed by...

A recent well publicized Ohio fatality highlights the simple truth that the oil and gas industry can be a dangerous business. This has been recognized by the Occupational Safety and Health Administration, better known as OSHA, which is charged with...

Pipeline integrity management programs are largely driven by regulatory compliance and are typically budgeted years in advance. Operators of all sizes are looking for ways to reduce expenditures related to operational efficiency and safety in order...