Introduction

Pipeline management remains fraught with safety risks for operators and the environment. Last year, the Ontario Energy Board determined that a $12 billion oil pipeline proposed by TransCanada Corp. would pose more risks than rewards for the province. The board estimated that a single oil spill could cost more than $1 billion and would contaminate drinking water and protected lands. While oil spills are extremely challenging to clean up, utility companies face similar challenges to maintain the health of and mitigate risks to their pipelines. In early 2016, the governor of California declared a state of emergency due to a broken injection-well pipe used to store methane gas. Methane is flammable and a dangerous pollutant for the atmosphere. This gas leak has been spewing at such a high rate that the well emissions account for a quarter of the state's total methane emissions. [1]

While pipeline safety incidents are still too prevalent, the industrial internet of things (IIoT) provides a great opportunity to improve efficiencies and operations. According to a collaborative report published by DHL and Cisco, 50 billion machines will be connected to the Internet by 2020 and there is $19 trillion in “Value at Stake” globally over the next decade. [2] However, just because everything is connected and creating massive amounts of data, doesn’t mean the bottom line sees immediate benefit. So the question is: How can all of this data be converted into useful information and used effectively?

Whether it’s a matter of preventing a major spill or leak, or identifying the initial signs of degradation, energy organizations must have a robust asset performance management (APM) system in place to increase the reliability of pipeline assets and maintain safety. By implementing an effective APM program, energy organizations will dramatically improve pipeline integrity and, as a result, see a direct improvement to their bottom line.

Pipeline Management Risks

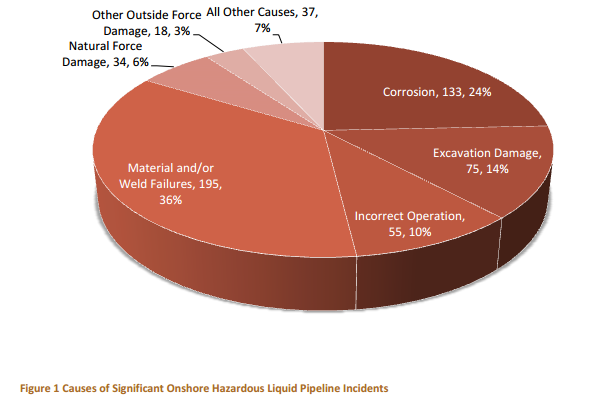

A significant portion of international energy products are transported through pipelines. Pipeline failures can be catastrophic and put a strain on both energy organizations and national economies. The most common causes of major incidents in pipelines include:

- Design or construction flaws

- Internal and external degradation, including cracks, pitting, corrosion, or loss of metal

- Soil movement, e.g. freezing and thawing

- Third-party damage

- Operational incidents

- Loss of containment

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.