In-Service AST Inspection and Cleaning Robotics

New Technology Allows Access to Coils with Common Headers in the Process Industry

Radiation Safety in Industrial Radiography

A Discussion on the Piping Thickness Management Process - Part 1

Corrosion Control Documents: One High Priority Approach to Minimizing Failures of Fixed Equipment

Evaluating Fitness for Service of Damaged Equipment

Global Refining Industry Utilizes Ultrasonic Inspection Technology

Announcing a Joint Industry Project on HTHA

Exchanger Girth Flange Evaluation

My Turbine Has Run For Years... Why Did it Fail Now?

Risk Based Inspection - Setting Risk Targets

Call for Nominations: 15th Annual Mary Kay O'Connor International Symposium

CSB Deploys Team to El Dorado, Arkansas to Investigate Fatal Hot Work Explosion

Electroless Nickel Surface Coatings

Integrity Management and the Oil and Gas Shale Plays

Internal Robotic Inspection Tool for Unpiggable Pipe Inspections

Is Your Flexibility Causing You Stress?

Recently Formed Nondestructive Evaluation Modeling and Simulation Center Already Yielding Results

Reliability and Integrity Analysis of an Air-Cooled Heat Exchanger: A Case Study

Swiss Cheese, Bow Ties and Normalization of Deviance

United States Chemical Safety Board Requests Comments on its Draft Strategic Plan for 2012 to 2016

2012 Inspectioneering Journal Article Index

Piping failures still represent a frustrating and ongoing problem for processing plants (example in Figure 1). Failures are commonly reported and contribute to large losses. As well per the author’s experience, piping still represents the...

Piping failures still represent a frustrating and ongoing problem for processing plants. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment...

Since its inception, one of the core businesses of the MS&R (maintenance, safety and reliability) Team for Kuwait Oil Company's NK (North Kuwait) Facilities has included carrying out Preventive Maintenance (PM) activities as directed by the...

We have recently learned of one organized joint industry project (JIP) that was announced at the Spring 2012 API Refining meeting. As information has become available we have decided to present it to our readership.

The Mary Kay O'Connor Process Safety Center is currently seeking nominations for the annual Merit Award and Harry West Memorial Service Award, to be presented at the 2012 Annual Symposium.

The design and fabrication of nuclear pressure vessels and piping components are governed by the rules of Section III of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. This Code, which aims to to ensure high...

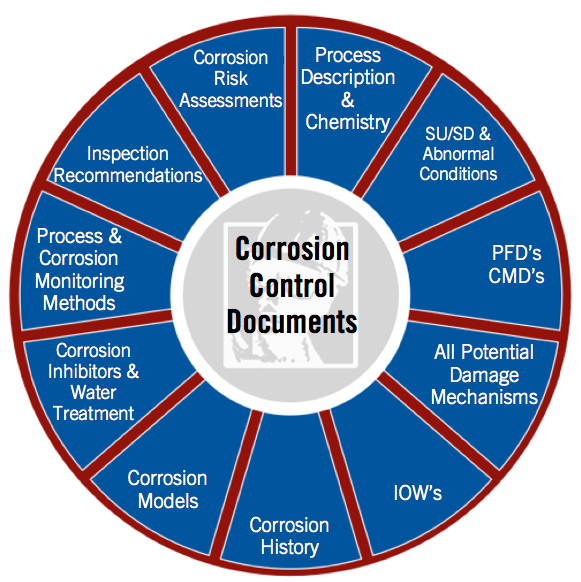

Perhaps the most important work process to achieve success in fixed equipment PEI&R is to create Corrosion Control Documents (CCD’s) for each process unit. In this article, I expand upon that work process in order to guide the interested...

The U.S. Chemical Safety Board (CSB) today deployed a four- person investigation team to El Dorado, Arkansas to determine the cause of an explosion and fire that severely burned and killed three workers.

Electroless nickel (ENC) is a family of coatings based on nickel-phosphorous metallic compounds. ENC was developed in 1943 by Abner Brenner, an electrochemist at the U.S. Bureau of Standards. While working on the electroplating of nickel onto...

Concerns about the reliability of ultrasonic in-service inspections conducted at nuclear power plants led the U.S. Nuclear Regulatory Commission (NRC) to draft a proposed qualification document in October 1984. Representatives from industry, the...

What I am primarily concerned with, in this article, is erosion corrosion control. Now, what is erosion corrosion? Well, no matter how you might look at it, erosion corrosion involves the degradation of the material by some mechanical action, in...

An all too familiar scenario in power plants is one in which an inspection finding occurs late in an outage and consequently, the return to service date may need to be postponed to allow time for corrective action. Historically, cracks or thinned...

At most operating facilities, a significant amount of time, effort, and money is expended on problem flanged joints that repeatedly leak. Joints that are repeatedly tightened online, that require installation of leak clamps, or that have resulted in...

The refining industry has applied ultrasonic-based intelligent pigging to inspect serpentine coils in fired heaters since the 1990s. Today, thousands of serpentine coils in fired heaters are inspected annually at process facilities around the globe.

A unique technique for inspecting and cleaning the floors of an Above Ground Storage Tank (AST) emerged in the late 90’s based on In-Service Robotic Technology. The technology has come a long way since then, with new inspection and tank cleaning...

On August 6, 2012, a piping failure occurred in the #4 Crude Unit at the Chevron U.S.A. Inc. refinery in Richmond, CA. Chevron U.S.A. would like to share some potentially significant preliminary information regarding the incident.

Development of shale requires the utilization of numerous types of fixed equipment. Due to the high cost and risk associated with hydrocarbon production and processing, E&Ps must continue to manage cost-effective and safe fixed equipment programs....

A self-propelled in-line inspection tool tested at Electric Power Research Institute and utilized in Europe can traverse a complex piping configuration and discriminate areas of metal loss. This tool is becoming available to inspect traditionally...

Flexible hose assemblies (FHAs) and flex joints are often used in designs to accommodate motion, misalignment, vibration, thermal expansion/contraction, and to simplify installations. Unfortunately, the inherent risks associated with these...

Thanks to constantly improving technology developments, inspection of atmospheric storage tanks has yielded better data which, when used as input, improves the accuracy of advanced assessment techniques. Coupling the improved inspection data with an...

Antea delivers highly flexible risk-based asset integrity software with 3D Digital Twin integration to optimize maintenance, reduce risk, and improve mechanical integrity for oil and gas, power generation, and chemical plants and facilities....

Learn how you can safeguard integrity, reliability, instrumentation safety, and more.

Steam turbines exist in most every major industrial facility. Many of these turbines have been running for years and have been very stable. Typically, after a period of time, the equipment is shut down for maintenance during a planned outage. It is...

Various fired heater designs in refineries and chemical plants contain common headers (e.g. Arbor coil configurations, CCRs, etc.) as part of their overall serpentine coil design. Accessing the interior of individual coils through the common header...

Radiography technique is one of the most widely utilized non-destructive methods, used in industry to evaluate the structural integrity or find out the hidden details of an assembled structure. Since this method uses ionizing radiation, it is...

The new capabilities being developed through the Nondestructive Evaluation (NDE) Modeling and Simulation Center are expect- ed to reduce the time, cost and complexity of approaches used to develop and demonstrate NDE techniques to meet regulatory...

Boiler and heat recovery steam generator (HRSG) tube failures have been the primary availability problem for operators of conventional fossil-fueled and combined-cycle power plants for as long as reliable statistics have been kept for each...

Air-cooled heat exchangers (AC-HEs) are used extensively throughout the oil and gas industry, from upstream production to refineries and petrochemical plants, under high pressure and high temperature conditions, as well as corrosive fluids and...

The question of how to set risk targets is a logical one and should be addressed prior to or in the very early stages of RBI implementation. This article will guide readers through the basic elements required to address this question within an...

As refiners continue operating aging infrastructure, safe operation and equipment availability continue to be key components of a sustainable operation. When considering optimizing inspection projects, more and more refiners are making Risk-Based...

The various factors of the challenge, e.g. creating effective and then efficient inspection strategies, are at the crux of the decision process. Within each of these factors are questions that must be answered. The answers should be well thought...

Risk Based Integrity Management (RBIM) is the latest process for developing strategies to properly operate and maintain a manufacturing or production facility in the Oil, Gas, and Petrochemical Industry (OG&P). RBIM is a significant change from...

Over the past 100 years, Nondestructive testing has made tremendous advances. New NDT methods have been introduced, while old "tried and true" methods continue to be improved. Although some NDT methods have drastically changed or "evolved" over...

This is the last out of the ten articles in this series. Clearly, Continuous Improvement (CI) has a major role in achieving excellence in PEI&R. All the advances we’ve made over the years in achieving excellence in PEI&R stems from our continuous...

Clearly, record-keeping and data management have a major role in achieving excellence in pressure equipment integrity and reliability (PEI&R). Everything else we do to achieve excellence in PEI&R stems from keeping high quality and complete PEI&R...

The U.S. Chemical Safety Board (CSB) today announced it is requesting public comments on its draft 2012-2016 CSB Strategic Plan. The draft plan is an update of the 2007 - 2012 CSB Strategic Plan, and includes the CSB's strategic goals, strategic...