| Date | May/June 2016 |

| Volume | 22 |

| Issue | 3 |

| Return to Journal Index | |

May/June 2016 Inspectioneering Journal Article Index

Data, in pure form, consists of raw, unorganized facts that need to be processed. Data can be found in databases, documents, drawings, reports, spreadsheets, and numerous other sources. Having data on hand is useful, however, it’s often...

Large scale capital projects present a myriad of challenges for owner-users in the oil and gas and petrochemical industries. Budgets are constantly being stretched and project deadlines are often exceeded. One area that deserves attention from all...

In the last few years, electromagnetic acoustic transducer (EMAT) has come to prominence for its ability to quickly scan exposed pipelines for corrosion, cracks, and other defects using medium-range guided waves and without the requirement for...

This brief article contains updates and highlights related to the Subcommittee on Inspection (SCI) at the 2016 API Spring Refining Equipment and Standards Meeting.

Statistical techniques are meant to complement the work of SMEs and can provide deeper insights into the inspection data collected as part of a reliability program. Pinnacle has combined traditional methods, expertise, and Machine Learning to...

RBI and NII are designed to achieve significant cost savings and risk mitigation benefits over a piece of equipment’s lifetime in the long term.

This is the second article of a two-part series published in Inspectioneering Journal, which is intended to provide a basis for understanding the differences between traditional tapped-transformer, fixed voltage type rectifiers, and High Frequency...

The main intention of this article is to introduce the Response Surface Methodology (RSM) using some of the elements of critical thinking as a guide. This methodology is not often used in the industry, but can be widely used by corrosion/process...

This paper identifies the attributes and benefits of a data and metrics-driven management system focused on process safety design integrity and reliability relative to loss of primary containment (LOC). This management system process focuses on the...

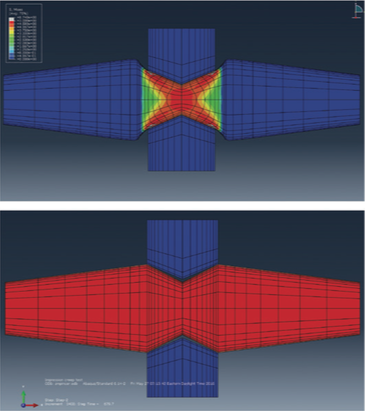

Aging equipment, along with more aggressive service, makes it more important than ever to carry out fitness-for-service (FFS) assessments in support of run/repair/replace decisions. Testing material in the service-degraded condition enables...