Sanjoy Das: About the Author

Scientific Officer - Quality Assurance Division, Bhabha Atomic Research Centre

Sanjoy Das received Bachelor Degree in Metallurgical Engineering, B.E. (Met), from Jadavpur University, Kolkata. He joined Bhabha Atomic Research Centre (BARC) in 1996 (40th class of BARC Nuclear Eng. Training School). He is level-III in radiography method (RT III) and level-II in ultrasonic test (UT II). His areas of expertise include Industrial Radiography, Digital Signal Processing (DSP), Wavelet Analysis, and Digital Image Processing.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

With the advent of digital technology, image processing can be done in digital radiographs which can be used for automated detection and quantification of defects. It is important to know the system's limitations and the probability of detection.

The structural integrity of components is controlled by material properties, the presence of flaws, and levels of applied stress. Several factors such as temperature, type of loading, toughness, corrosion resistance, micro-structural stability, cost etc. dictate the suitable material for the desired application.

The Modulation Transfer Function (MTF) is used in imaging science to assess the reliability of imaging systems to produce different spatial frequency. In digital radiography, it can be used to detect frequency responses of different inspection conditions.

Radiography technique is one of the most widely utilized non-destructive methods, used in industry to evaluate the structural integrity or find out the hidden details of an assembled structure. Since this method uses ionizing radiation, it is important to ensure not only the quality of product, but also the safety of the technician and the general public, as well as the protection of the environment.

Rapid industrial and technological growth throughout the world makes it necessary to develop new materials along with advanced Non-Destructive Testing (NDT) Methods to ensure their quality without premature failures. The complex modern system, where materials are required to perform consistently with optimum efficiency, demands stringent quality control of engineered components.

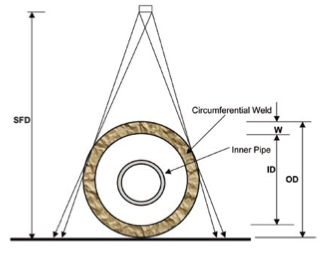

Most common radiographic practices for circumferential weld testing are single wall and double wall techniques with certain variations in technique details. Different Codes deal with the number of exposures required and applicability of the technique for different combinations of pipe diameter and wall thickness. However, there are certain geometries where these conventional radiography techniques are not applicable, mainly because the weld is superimposed on some structural material inside the tube or pipe.

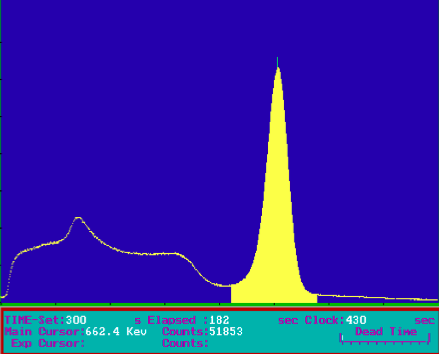

Degradation of materials with time during service is a common phenomenon for all engineering components. Hence periodic inspection is required to ensure structural integrity and availability for service. During in-service inspection (ISI), wall thickness measurement of insulated and non-insulated pipe is a typical non-destructive evaluation technique in the oil & gas, chemical, petrochemical and nuclear industries. Ultrasonic testing is available for wall thickness measurement, but in some cases, it may not be the preferred technique. For ultrasonic testing, accuracy is dependent on the temperature of pipe, which may carry fluid at high temperature. Hence shutdown of the installation is required. Moreover for insulated pipe, insulation has to be removed before ultrasonic testing. The radiation technique is a complementary testing method which can be carried out without disturbing the installation. In this technique electromagnetic radiation passes through the object of inspection and is finally recorded in a recording medium. The recording medium is either an industrial X-ray film or a radiation detector. This paper is devoted to detection of pipe wall thinning by the radiation technique. Two different methods i.e. radiography and radiometry, are discussed with their relative merits and demerits.

Radiography is the most widely used volumetric examination technique for non-destructive evaluation of components, as it offers the advantage of direct viewing of the flaw image, judging the type of flaw and provides a permanent record. Flaw characterization methods, described by size, shape & Location, require classification of the type or nature of flaw, position of flaw and flaw severity. Accurate sizing of the flaw to assess its severity is important. ISO Guide 25 "General Requirements for the Competence of Calibration and Testing Laboratories" (1990), requires one to specify the uncertainty of each measurement. In radiography there are several factors which contributes to uncertainty for quantitive measurement. This paper describes a study undertaken to calculate the uncertainty in flaw sizing and to estimate the real size of discontinuities observed in radiography.