Advanced Digital Radiography Systems and Image Processing Operations in Radiography Inspection

Avoiding HTHA Failures in Existing Equipment

California Emphasis Program - Naphtha Hydrotreater Units - High Temperature Hydrogen Attack

High Temperature Hydrogen Attack (HTHA) Likely Cause of Explosion

High Temperature Hydrogen Attack Recent Progress and Where To Aim Joint Industry Activities

PAS 55 - Optimal Management of Physical Assets Specification

Update on Pipeline Management and Rules and Pipeline Integrity Management Systems (PIMS)

Advancements in Integrity Management - Obtaining Greater Value from Thickness Data

CSB Issues Final Report on Allied Terminals Catastrophic Fertilizer Tank Collapse

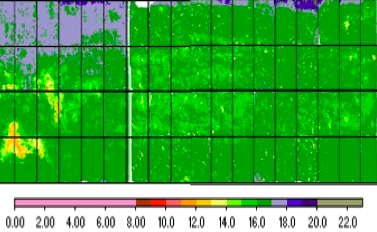

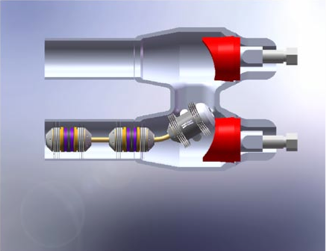

Detection of Corrosion Under Insulation and Blockages on Piping System Using Profiler System

Ethylene Unit Fire Lessons Learned - Sunoco Marcus Hook, PA Refinery

Integrity Operating Windows and Management of Change for Pressure Equipment Integrity

2010 Inspectioneering Journal Article Index

Rapid industrial and technological growth throughout the world makes it necessary to develop new materials along with advanced Non-Destructive Testing (NDT) Methods to ensure their quality without premature failures. The complex modern system, where...

Inspection intervals for equipment have in the past been defined in a prescriptive manner. However, industry is now embracing the Risk Based Inspection (RBI) approach which in contrast prioritises inspections based on an assessment of the risk to...

High Temperature Hydrogen Attack (HTHA) is a long known and still occurring degradation issue for fixed equipment construction materials in the hydrocarbon process industry where hydroprocess plants (hydrogen plus hydrocarbons) are in service....

Washington, DC, January 25, 2010 - The U.S. Chemical Safety Board (CSB) today voted to initiate an investigation of recent accidents at the DuPont chemical complex in Belle, West Virginia, following a release of highly toxic phosgene on Saturday...

The OmniScan™ X3 64 phased array and TFM flaw detector is equipped with enhanced phased capabilities and even faster TFM. The rugged and portable instrument features powerful 64-element probes with a 128-aperture TFM.

On April 6, 2010, a tragic accident occurred at the Tesoro Refinery in Anacortes, WA, in the Naphtha Hydrotreater process unit (NHT). During routine operations involving an on-line switching of unit heat exchanger feed trains, seven employees were...

In a report issued May 27, 2009 for an investigation into the November 2008 fertilizer tank collapse at Allied Terminals in Chesapeake, VA, the U.S. Chemical Safety Board (CSB) recommended that the Commonwealth of Virginia regulate or authorize...

The U.S. Chemical Safety Board (CSB) issued urgent safety recommendations calling on CITGO to immediately improve its emergency water mitigation system in the event of another release of potentially deadly hydrogen fluoride (HF) vapor, as occurred...

Washington, DC, June 7, 2010 - The U.S. Chemical Safety Board (CSB) today released a 14-minute safety video warning of the hazards of welding and other hot work activities in and around storage tanks containing flammable materials.

CUI (Corrosion Under Insulation) has always been a challenge for plant operators, quality assurance/reliability engineers and equipment owners. It is hard to identify the problem until it has become an emergency situation, often leading to unit shut...

At approximately 10:15 p.m. on Sunday, May 17, 2009, there was a sudden and large hydrocarbon release from a main process pipe in the Ethylene Unit at the Sunoco Marcus Hook, Pennsylvania Refinery. The release found an ignition source at an...

Per a report in Downstream Today, by Whitney Pipkin Skagit Valley Herald, Mount Vernon, Knight Ridder/Tribune Business News on August 30, 2010, "Tesoro Anacortes Refinery announced Friday what investigators determined was the likely cause of an...

Understanding, predicting, detecting and controlling high-temperature hydrogen attack (HTHA), have been elusive goals of materials engineers and scientists for over 70 years. The destruction of low alloy steel components exposed to hydrogen through...

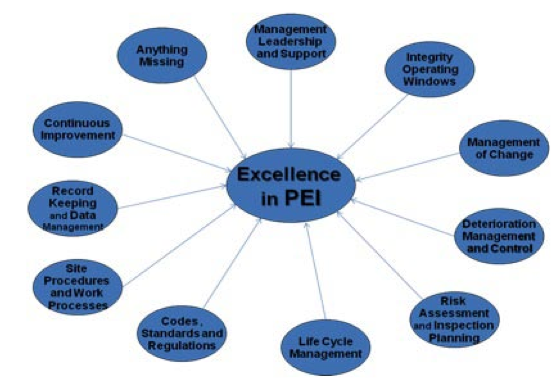

This article in the series will focus on two more of the necessary MSs for achieving excellence in PEI: Integrity Operating Windows (IOWs) and Management of Change (MOC).

Like all of the other 10 MSs in our filing cabinet, this MS on Management Leadership and Support of PEI (shown in Figure 2 below) is vital to success and linked inextricably to all the other PEI MSs.

This recommended practice (RP) identifies leading and lagging process safety indicators useful for driving performance improvement and includes mechanical integrity related items. As a framework for measuring activity, status, or performance, this...

This is a Publicly Available Specification (PAS) published by the British Standards Institution (BSI). PAS 55 gives guidance and a 28-point requirements checklist of proposed good practices in physical asset management; typically this is relevant to...

Washington, DC, May 19, 2010 - The practice of using flammable natural gas to clean power plant piping, which led to the fatal explosion at Connecticut-based Kleen Energy on February 7, has been commonly used across the gas-fired power generating...

In coordination with a team of research partners, including BP, PHMSA, GL Noble Denton (formerly Advantica), and Electricore, Pipeline Research Council International (PRCI) recently completed the consolidated program on assessing the remaining...

For years refinery and chemical plant operators have utilized ultrasonic-based intelligent pig technology to inspect coils in convection and radiant sections of fired heaters. This proven technology provides accurate inspection data which allows...

This article describes the API Risk-Based Inspection (RBI) methodology for pressure relieving devices (PRDs) as detailed in the soon to be released 2nd edition of API 581 "Base Resource Document On Risk-Based Inspection" This methodology has been...

The following references are from the American Petroleum Institute. They are widely used in the petroleum refining and petrochemical industries for managing equipment in HTHA service and are available in the public domain.

Clearly, corrosion prevention and control has a major role in achieving excellence in Pressure Equipment Integrity and Reliability (PEI&R). But there is a lot more to PEI&R than just corrosion control. This article will show how corrosion control...

Statistical techniques are meant to complement the work of SMEs and can provide deeper insights into the inspection data collected as part of a reliability program. Pinnacle has combined traditional methods, expertise, and Machine Learning to...

In the first article in this series entitled How to Put It All Together - Guide to Organizing a Successful PEI Program, (1) I provided an overview of the necessary Management Systems (MS) for a successful program to achieve excellence in pressure...

As the oil and gas industry matured regulators and the public have become more and more aware of the risks inherent in the business and increasingly require pipeline owners to demonstrate and document the safe and environmentally acceptable...

For years the WRC has provided the documented technical basis for many decisions made regarding design, repair, remaining life estimation, and fitness for service of pressure equipment in our industries. Many codes and industry recommended practices...