The Application of Risk Based Inspection (RBI) and Evolution to Risk-Centered Maintenance

Risk Based Inspection (RBI) - The Current State

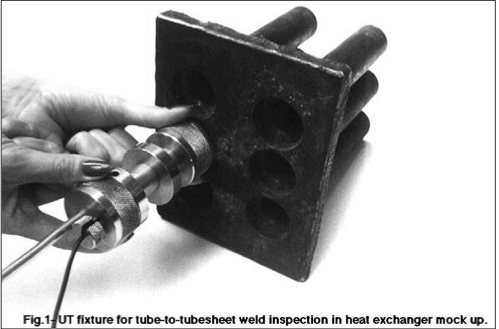

UT Inspection for Cracking in Heat Exchanger Tube-to-Tubesheet Welds and Tube Corrosion

Measurement of Sludge Volume in Crude Oil Storage Tanks

Mechanical Integrity Management Using Remaining Wall Thickness and Data Analysis - Part 2

Complete Volumetric Inspection of In-Service Vessels and Piping Using EMAT Ultrasound

Mechanical Integrity Management Using Remaining Wall Thickness and Data Analysis

Rapid Screening Improves Heat Exchanger Reliability

1999 Inspectioneering Journal Article Index

The API Subcommittee on Inspection (SCI) has determined to initiate a program covering the qualification of ultrasonic (UT) technicians conducting inspections.

In two previous issues we discussed the important difference between steady and cyclic loading, and why loose bolts fail while tight ones do not. This issue will offer two suggestions for reducing the tendency for bolts to become loose.

In the previous issue, we dealt with the fact that bolts can withstand significantly less cyclic loading then steady loading. We are now looking at the mechanics of why bolts fail if flanges are allowed to separate during operation.

EMATs (Electromagnetic Acoustic Transducers) have been used for over six years for field service inspection of in-service piping. Recent advances in technology have allowed us to inspect new types of on-stream piping.

Steam reformers are an integral part of ammonia, methanol, hydrogen, and gas process plants around the world. THey are one of the highest cost, both in capital and maintenance, pieces of equipment in the plant. Typically, reformers contain several...

The new Sludge Profiler for Oil Tanks system (S.P.O.T.) solves the major problem of accurately quantifying the volume of sludge in oil storage tanks with floating roofs.

Keeping critical equipment on-line can be a challenging task. Monitoring the wall thickness of equipment subjected to corrosive chemicals, temperature and operational changes is both a safety and manufacturing concern. Thus, on-line testing of...

Many digital ultrasonic thickness gauges have internal memory that allows the storage of thousands of thickness readings. Some instruments have "sequential" data loggers that store the thickness values in a numerical series. These data loggers are...

One of the greatest challenges facing many of refining, fossil power, and pulp and paper industries is: How to effectively examine their insulated piping?

Southwest Research Institute (SwRI) has developed an innovative method for rapid screening of heat exchanger tubing using Guided Wave technology. This screening method can lead to an improvement in heat exchanger reliability and a reduction in the...

Here are some of my observations based on numerous discussions with owner users and involvement in over 30 projects. This learning is from plant operators who have taken the RBI "plunge", after they have had time to think about their decisions and...

There are many analysis tools available in the market that lay hold of the "RBI" claim. I wanted to bring you, the reader, "up to speed" on some of the available technology based on my experience as an RBI project manager, client manager and member...

Companies have developed detailed programs for managing wide range of assets. However, unsustainability negatively impacts effectiveness of these programs. Reach out to us on how we can address sustainability through digital transformation.

Some Middle Eastern and European operators are now using AE successfully to screen tanks for internal inspection by listening for active tank bottom corrosion, and then grading the tank as high, medium or low need for internal inspection.

Ultrasonic thickness monitoring programs represent one of the most intensive inspection activities in refining and petrochemical facilities. Despite numerous improvements in ultrasonic testing equipment and inspection techniques, however, there has...

Inspection data analysis tools, like risk-based inspection, help us to focus on quantitative reliability targets. When considering thinning mechanisms, there is a certain probability that a piece of equipment will reach retirement thickness before...

Risk based inspection, RBI, is a method currently changing how corporations view their maintenance programs. Application of a systematic analysis process that focuses on the likelihood of a given failure and the consequence of this failure happening...

This paper describes the use of a UT fixture for detection of stress corrosion cracking in ferrous heat exchanger tube-to-tubesheet welds and external tube corrosion or pitting near the tubesheets including crevice OD corrosion.

This is part three of a three part article for the IJ describing some of the advanced on-stream inspection (OSI) methods available for use in inspection of pressure equipment in the petroleum and petrochemical industry. These methods can be used,...

This is part two of a three part article describing some of the advanced on-stream inspection methods available for use in inspection of pressure equipment in the petroleum and petrochemical industry. These methods can be used, under the right...

This three-part article describes some of the advanced on-stream inspection methods available for use in inspection of pressure equipment in the petroleum and petrochemical industry. These methods can be used, under the right circumstances, to...