Introduction

Corrosion and cracking present problems for every industry that relies on pipelines to transport liquid and gas products. There are many different kinds of techniques and equipment used for examining pipelines. These vary based on specific needs, access restrictions, and environmental conditions. In the last few years, electromagnetic acoustic transducer (EMAT) has come to prominence for its ability to quickly scan exposed pipelines for corrosion, cracks, and other defects using medium-range guided waves and without the requirement for liquid couplants.

Recent sensor and technique developments have now enhanced these capabilities to reliably inspect inaccessible or difficult to access areas for corrosion, such as the undersides of pipe supports and pipes with heavy coatings.

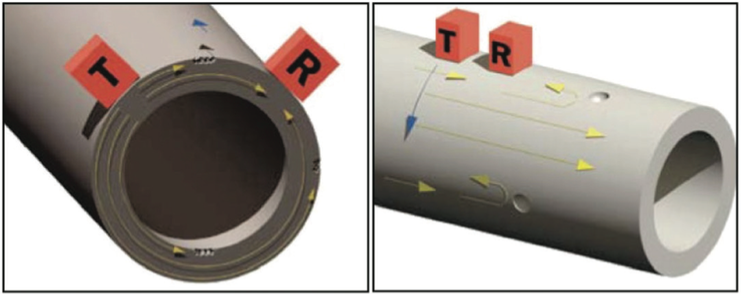

Axial and Circumferential Scanning with MRUT

Long range ultrasonic testing (LRUT) uses encircling rings to generate guided waves that can detect moderate defects over long distances on relatively clean pipes. One of the main disadvantages of this technique is that it has an uninspectable dead zone of approximately 1-2 meters in front of the transducer, which makes it inappropriate for small distances and where valves, connections, or other components are present.

EMAT-generated medium range ultrasonic testing (MRUT) lamb waves have been used for axial scanning using attenuation techniques for several years. This technique permits fast scanning of exposed pipe with great detection capabilities. However, its use in reflection mode (circumferential scanning) for inspecting inaccessible areas has been limited because lamb waves can leak into coatings and supports, which restricts its practical use in the field.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.