Ultrasonic Testing (UT) is a group of nondestructive examination (NDE) techniques that use short, high-frequency ultrasonic waves to identify flaws in a material. They generally work by emitting waves into a material. By measuring these waves, the properties of the material and internal flaws can be identified. Most UT devices consist of many separate units. These can include pulsers and receivers, transducers, and display monitors. The components included depend on the type of UT that the inspector is performing.

FREE RESOURCE: Click here to download a more detailed overview of UT.

Types of Ultrasonic Testing

There are several different types of ultrasonic testing, including:

Automated Ultrasonic Backscatter Technique

Advanced Ultrasonic Backscatter Technique (AUBT) is a UT technique developed for detecting damage from High-Temperature Hydrogen Attack (HTHA). The technique is for use in pressure vessels and piping. The technique makes use of high frequency, broadband UT probes and a digital oscilloscope. These allow it to provide both an A-Scan display and frequency analysis.

Phased Array Ultrasonic Testing

Phased Array Ultrasonic Testing (PAUT) is a UT technique that utilizes a set of UT probes made up of numerous (anywhere from 16 to over 250) small elements. Each of the elements in a PAUT system is able to pulse individually. This is done with computer calculated timing, through a process known as phasing. This allows the system to steer focused beam through various angles and focal distances.

Long Range Ultrasonic Testing

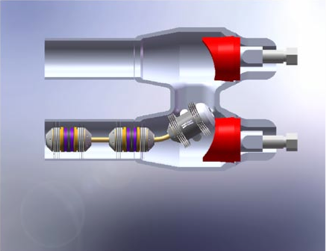

Long Range Ultrasonic Testing (LRUT) is a UT method developed to allow for testing large volumes of material from a single test point. This method works by fixing transducer rings uniformly around a pipe. These rings then generate a series of low frequency guided waves. The waves can then propagate symmetrically along the pipe axis. This provides complete coverage of the pipe wall.

Internal Rotating Inspection Systems

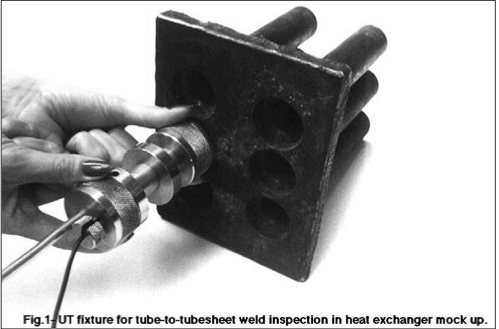

An Internal Rotating Inspection System (IRIS) is an ultrasonic technique used to detect corrosion in piping and tubing. using an internally inserted probe that generates sound waves. The system works by inserting a probe into a flooded pipe. The probe them move through the pipe, scanning as it goes.

Time of Flight Diffraction

Time of Flight Diffraction (TOFD) is a method used to look for flaws in welds. It uses the time of flight of an ultrasonic pulse to find the location of a reflector. To find the TOF, the method uses a pair of ultrasonic transducers. The transmitter emits low frequency waves that propagate at an angle. They only diffract back to the receiver if they hit a defect.

Dry-Coupled Ultrasonic Testing

Dry-Coupled Ultrasonic Testing (DCUT) is an alternative, low-cost method that does not require a liquid couplant to inspect metallic and nonmetallic material. Additionally, DCUT transducers are capable of withstanding high voltages. DCUT is a versatile method that can be performed using flexible, contact, wheel, or remote transducers.

- Flexible transducers can be applied on an external or internal surface of a component to detect flaws.

- Contact transducers are also used to detect flaws as well as thickness measurements.

- Wheel transducers allow inspectors to inspect long piping systems in a short amount of time.

- Remote transducers are advantageous because they can take thickness measurements at non-conventional angles (i.e., at angles that are not 90° to the surface). This eliminates the need to build supports or remove components in order to perform inspection.

Rapid Ultrasonic Gridding (RUG)

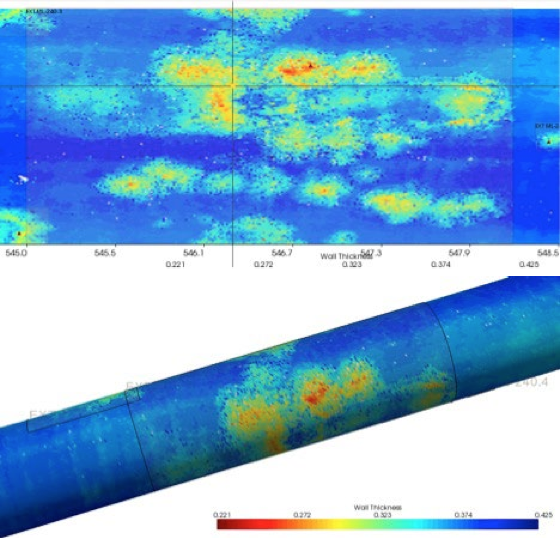

Rapid Ultrasonic Gridding (RUG) is an NDE method of performing ultrasonic thickness in which multiple ultrasonic thickness probes are utilized, simultaneously, to rapidly gather thickness measurements in a predefined or ad hoc space. Like other UT methods, RUG captures raw A-Scan data, which can be presented in B-Scan or C-Scan modes — or used to create visual representation as 3-D models. However, RUG is capable of capturing multiple A-Scan data points at a much faster rate than traditional thickness measuring techniques.

Advantages and Disadvantages

In general, UT has several advantages and disadvantages. It’s useful because it can scan for flaws both on and underneath the surface. It is also useful for it's incredible accuracy. On the other hand, not all materials are receptive to ultrasonic testing. It also has the disadvantage that it requires a good deal of skill and training to perform.

Related Topics

- Acoustic Emission Testing (AET)

- Advanced Ultrasonic Backscatter Technique (AUBT)

- Eddy Current Testing (ECT)

- Electro Magnetic Acoustic Transducers (EMAT)

- Guided Wave Ultrasonics (GWUT)

- Infrared Inspection

- Liquid Penetrant Examination (LPE)

- Magnetic Flux Leakage (MFL)

- Magnetic Particle Testing (MPT)

- Meandering Winding Magnetometer Array (MWMA)

- Pulsed Eddy Current (PEC)

- Radiography

- Remote Field Eddy Current (RFEC)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition