| This article is part 3 of a 5-part series. |

| Part 1 | Part 2 | Part 3 |

| Part 4 | Part 5 |

Introduction

Piping failures still represent a frustrating and ongoing problem for processing plants (example in Figure 1)1. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment failures in petroleum refining. Of course, there are many factors within a pressure equipment integrity program (PEIP) that can contribute to piping integrity problems including design issues, operating window compliance, management of change issues, etc.

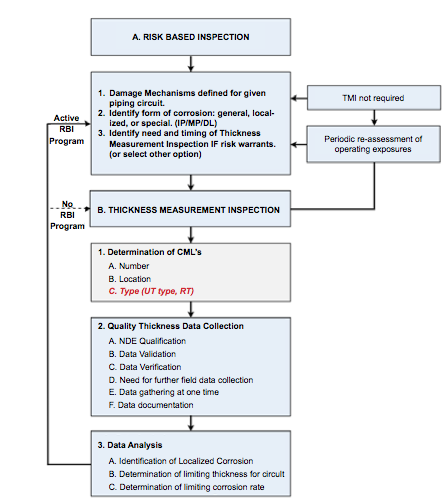

This article is the third of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping: thickness monitoring programs for internal corrosion. These articles will discuss what constitutes an effective piping thickness monitoring process and will present several practices that may be new to some readers, but these practices have produced beneficial results in other major piping reliability programs. The first article (September/October 2012 Inspectioneering Journal) provided an overview of this process as outlined in Figure 2. The second article (November/December 2012 Inspectioneering Journal) discussed the considerations that factor into determining the number and position of corrosion monitoring locations (CMLs). This article, Part 3, will discuss the benefits and limitations of using ultrasonic (UT) and radiography (RT) thickness data collection techniques.

It is important to keep in mind that this series of articles focuses only on thinning, or corrosion, which in many plants, is the most prevalent form of degradation. However, there are numerous other mechanisms that can lead to piping failures such as high temperature creep, fatigue, de-alloying, environmentally assisted cracking (e.g. chloride SCC), etc. Effective inspection strategies should be developed to detect the particular types of anticipated or potential damage as appropriate.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.