Radiographic Testing (RT) is a nondestructive examination (NDE) technique that involves the use of either x-rays or gamma rays to view the internal structure of a component. In the petrochemical industry, RT is often used to inspect machinery, such as pressure vessels and valves, to detect flaws. RT is also used to inspect weld repairs.

Compared to other NDE techniques, radiography has several advantages. It is highly reproducible, can be used on a variety of materials, and the data gathered can be stored for later analysis. Radiography is an effective tool that requires very little surface preparation. Moreover, many radiographic systems are portable, like robotic technology services, which allows for use in the field and at elevated positions. Advanced, automated radiography (ART) systems have been developed to significantly improve defect identification and enable more informed planning to optimize inspection and maintenance costs.

Types of Radiography

There are numerous types of RT techniques including conventional radiography and multiple forms of digital radiographic testing. Each works slightly differently and has its own set of advantages and disadvantages.

Conventional Radiography

Conventional radiography uses a sensitive film that reacts to the emitted radiation to capture an image of the part being tested. This image can then be examined for evidence of damage or flaws. The biggest limitation to this technique is that films can only be used once and they take a long time to process and interpret.

Digital Radiography

Unlike conventional radiography, digital radiography doesn’t require film. Instead, it uses a digital detector to display radiographic images on a computer screen almost instantaneously. It allows for a much shorter exposure time so that the images can be interpreted more quickly. Furthermore, digital images are of much higher quality when compared to conventional radiographic images. With the ability to capture high-quality images, the technology can be utilized to identify flaws in a material and foreign objects in a system, examine weld repairs, and inspect for corrosion under insulation (CUI).

Commonly utilized digital radiography techniques in the oil & gas and chemical processing industries are computed radiography, direct radiography, real-time radiography, computed tomography, and automated radiographic testing.

Computed Radiography

Computed radiography (CR) uses a phosphor imaging plate that replaces film in conventional radiography techniques. This technique is much quicker than film radiography but slower than direct radiography. CR requires several extra steps compared to direct radiography. First, it indirectly captures the image of a component on a phosphor plate, then converts the image into a digital signal that can be visualized on a computer monitor. Image quality is fair but can be enhanced using appropriate tools and techniques (i.e., adjusting contrast, brightness, etc. without compromising integrity). It’s important to know how tools, such as adjusting contrast, affect the image. Care should also be taken to make sure minor defects are not hidden after enhancements are made.

Direct Radiography

Direct Radiography (DR) is also a form of digital radiography and is very similar to CR. The key difference lies in how the image is captured. In DR, a flat panel detector is used to directly capture an image and display that image on a computer screen. Although this technique is fast and produces higher-quality images, it is more costly than CR.

Real-Time Radiography

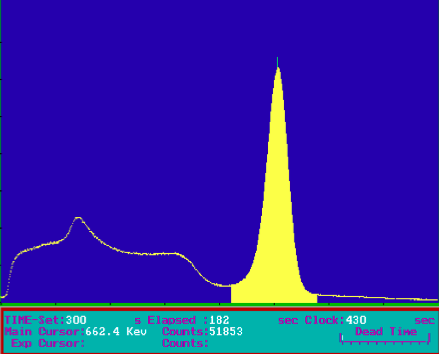

Real-time radiography (RTR), like its name suggests, is a form of digital radiography that occurs in real-time. RTR works by emitting radiation through an object. These rays then interact with either a special phosphor screen or flat panel detector containing micro-electronic sensors. The interaction between the panel and the radiation creates a digital image that can be viewed and analyzed in real-time.

The brighter areas on the image are a result of higher levels of radiation that contact the screen. This corresponds to the thinner or less dense section of the component. Conversely, darker areas are a result of less radiation interacting with the screen and indicate where the component is thicker.

Aside from being able to make the images available more quickly and analyze them in real-time, RTR has several other advantages. One advantage is that digital images don’t require physical storage space and thus are easier to store, transfer, and archive than film.

On the other hand, this method has several disadvantages as well. Compared to conventional radiography, RTR has a lower contrast sensitivity and limited image resolution. Images created via RTR often suffer from uneven illumination, limited resolution, a lack of sharpness, and noise. These factors have a major impact on image quality.

Computed Tomography

Computed tomography (CT) is a technique that takes hundreds to thousands (depending on the size of the component) of 2D radiography scans and superimposes them to create a 3D radiographic image.

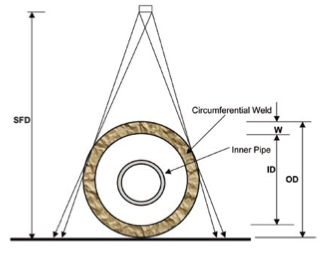

In an industrial setting, CT can be achieved in two ways. In one method, the component to be inspected remains stationary while the radiation source and x-ray detector rotate around the component. This technique is more likely to be utilized for large components. The second method consists of the radiation source and x-ray detector remaining stationary while the component is rotated 360 degrees. This second technique is more useful when the component is small or has complex geometry.

Although this technology is timely, expensive, and requires a large amount of data storage, CT provides highly accurate images, is repeatable and reproducible, and minimizes human error.

Automated Radiographic Testing

Automated radiographic testing (ART) was developed to provide a faster, safer, and more consistent means of detecting CUI and internal corrosion in above-ground piping and pipelines. ART utilizes a semi-autonomous motion control platform that carries safe, low-level X-ray emitters projecting onto complementary metal oxide semiconductor (CMOS) and photon detectors that produce radiographic mapping in fractions of a second. This allows providers who utilize robotic technology services to radiographically map large regions of interest in significantly less time than traditional methods and immediately displays a digital image for on-site evaluation. ART is ideally used for initial screenings of large pipe sections to identify potential corrosion without the need to take lines out of service or remove insulation for inspection.

FREE RESOURCE: Click here to download a more detailed overview of Radiography.

Related Topics

- Acoustic Emission Testing (AET)

- Advanced Ultrasonic Backscatter Technique (AUBT)

- Eddy Current Testing (ECT)

- Electro Magnetic Acoustic Transducers (EMAT)

- Guided Wave Ultrasonics (GWUT)

- Infrared Inspection

- Liquid Penetrant Examination (LPE)

- Magnetic Flux Leakage (MFL)

- Magnetic Particle Testing (MPT)

- Meandering Winding Magnetometer Array (MWMA)

- Pulsed Eddy Current (PEC)

- Remote Field Eddy Current (RFEC)

- Ultrasonic Testing (UT)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition