Introduction

This article addresses a debate mechanical integrity professionals in the O&G and Chemical Processing industries periodically have about how thickness data gathered during a thickness monitoring inspection (TMI) should be recorded. The question is whether during a new TMI, a thicker reading than the previous thickness reading should be recorded as the current entry in the thickness management database, or should it be ignored and the previous thinner reading entered?

Unfortunately, there is little information or industry standards addressing the specifics of how to handle TMI data. API 5701 and API RP 5742 provide high level guidance on TMI programs, but fall short on instructing users how to meet the high level objectives outlined. The OSHA 3132 PSM3 Mechanical Integrity section merely provides general guidance: “Inspection and testing must be performed on process equipment, using procedures that follow recognized and generally accepted good engineering practices.“ I have written several articles in the past for Inspectioneering Journal that have provided some considerations for what constitutes effective thickness management practices. This article will provide some specifics on collecting and analyzing individual test point thickness readings to account for apparent thicker data collection and some recommendations on thickness data recording.

Are Thicker Readings Valid Measurements?

There are two primary data gathering arguments when an inspector encounters a thicker reading at a thickness monitoring location test point than was previously recorded. The first is that such a reading must be erroneous and reflects negatively on the user’s TMI process quality assurance program. The second argument is that entering thicker readings generates increased noise (negative corrosion rates, high short term rates) around the single test point’s corrosion rate calculations, making interpretation of true corrosion rates difficult. I will address these arguments within this article and demonstrate that yes, thicker readings are quite valid and are also useful in the overall assessment of the piping circuit condition.

Variance of a Test Point Reading is Very Real

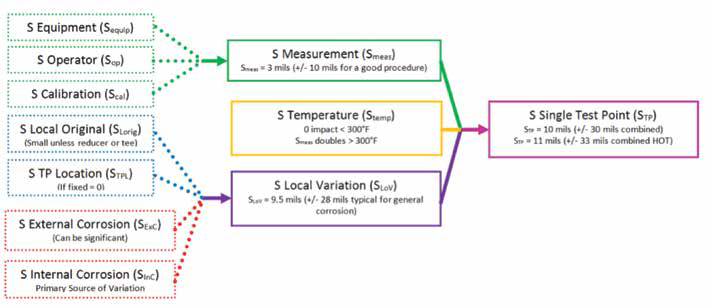

Any test determination, such as an ultrasonic thickness reading, taken at a single test point will have sources of variability that affect the accuracy of the result10. Figure 1 outlines the many sources of variation that can contribute to the overall accuracy (precision) of a test point reading. The measure of variation used here is the standard deviation (Sxx (sigma, σ)) for any particular contributor to the final test determination. The total range of variability in this assessment is assumed to be ± 3 sigma (99.7% of repeated readings will fall in this range). This example covers nominal thickness pipe below 0.500” thick. Thicker pipe will have more variability. Typically a 10% variability factor (coefficient of variance = CV) would be used to estimate the amount of potential variance in thicker pipe. Some key variability observations can be seen in Figure 1.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.