Data Management refers to the process of collecting and organizing data in a way that makes it useful and easy to retrieve, navigate, and read at a later date. Over the course of a single day, the average facility will generate immense amounts of data. This data includes things such as pressure, flow, and conditions of various pieces of equipment such as pipelines, valves, and pressure vessels.

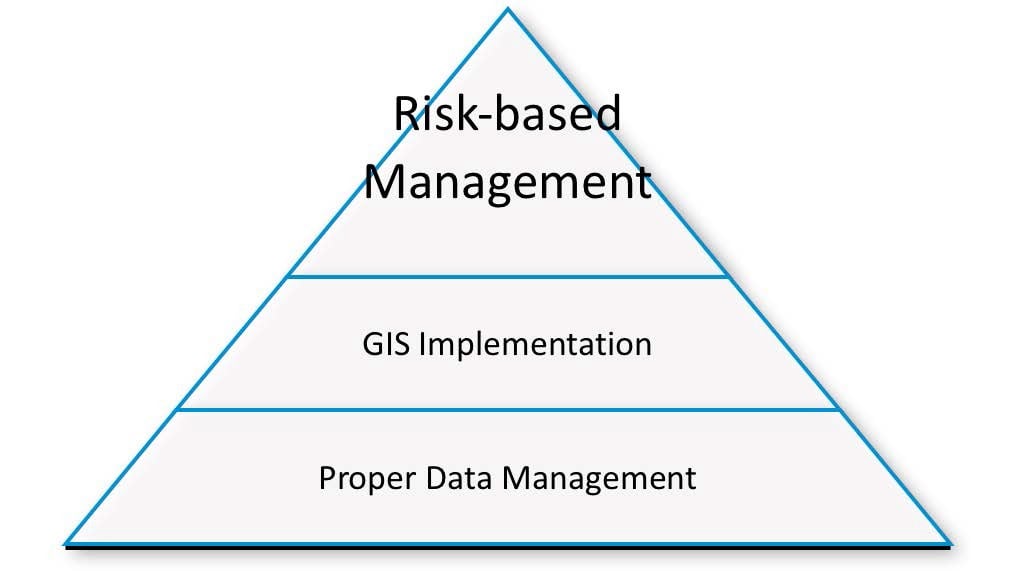

Whether in the downstream refining, midstream, renewable, offshore, chemical, or other sectors, proper data management is important for effective Asset Integrity Management programs, which require large amounts of data to be easily archived, accessed, and holistically analyzed. Facilities and vendors have developed software that can collect, manage, and analyze asset integrity data to drive actionable insights to enhance operations.

Inspection Data Management Software

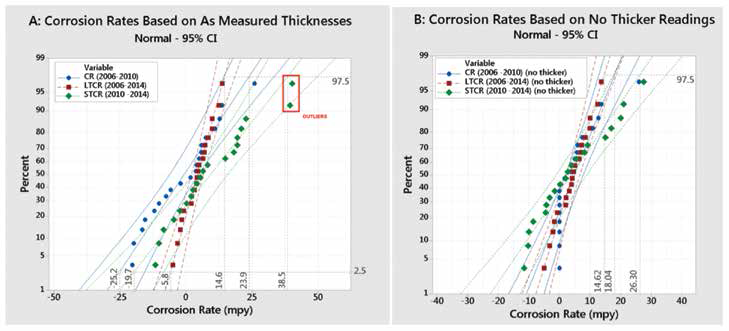

Data management can be a complex process. This is because data can come from various incompatible sources, such as multiple types of nondestructive testing (NDT) tools and online monitoring systems, that have been collected months or even years apart with different levels of completeness and complexity. Integrating these distinct sources of data together can be difficult, which is where an effective data management system and an experienced data management partner can provide crucial support.

A comprehensive inspection data management software (IDMS) solution can specialize in asset integrity, corrosion, and more to efficiently store data and help ensure assets meet industry regulations. Not only can advanced IDMSs store data but they can also analyze and generate actionable insights from the data that empower operators to make more informed inspection, mitigation, and repair decisions.

From inspection tracking and analysis to corrosion analysis and trending, an IDMS provides solutions to execute mechanical integrity (MI) initiatives and make data management as reliable as possible in the digital age.

Mechanical Integrity Data Integration

Integrated metrics can tell the entirety of a company’s data story. The future of asset integrity within refineries and plants lies within the benefits of an integrated data highway. For the downstream sector, the oil & gas industry has introduced a data management solution that supports every aspect of MI data management. With IDMS systems and mobile data management platforms working in sync, the integration of data has never been more useful or accessible.

An Asset Performance Management (APM) application allows oversight of multiple assets across multiple facilities on one platform. With an IDMS and mobile inspection reporting platform, an APM application can be automatically updated, avoiding the need for personnel to manually input data. This increases transparency in the inspection process and helps operators more effectively meet compliance requirements.

Oil & gas organizations can simplify the process of integrating data from multiple inputs by partnering with organizations that specialize in a wide variety of asset protection solutions. Rather than retroactively integrating incompatible data from multiple sources (such as data from drones, inline inspections [ILI], NDT, and online monitoring systems), relying on a single vendor to execute each of these activities helps ensure that data collected at any point during operations can be easily stored and analyzed in a central location.

Digitized Mechanical Integrity Data

In the digital age, plant operators can benefit greatly by transitioning from traditional, paper-based inspection reporting methods to mobile, digitized operations. Digitized data is an increasingly notable method for data management and is made possible through mobile inspection data reporting tools.

Advanced mobile inspection data reporting platforms have developed into mobile cloud-based field inspection, execution, and reporting solutions. Through the use of handheld devices in the field, mobile inspection data reporting platforms allow technicians to develop reports directly on their device and send that information dynamically to an IDMS, thus removing the time and manpower inefficiencies that can be present when inspectors have to manually enter data into the IDMS. This streamlining of work has improved time and work considerations for plants.

Data Management Advantages

The advantages of proficient data management are apparent within every aspect of operations. Data management as accomplished through proficient IDMS and mobile data reporting solutions can result in time and cost savings for the plant. The streamlining capabilities allow inspection work to occur faster and data to be visible in real-time. Data management allows post-inspection work to be more informed and relevant since the data is easily organized and stored properly. These advantages reach even greater heights when effective data management is done in conjunction with a provider that has the knowledge and capabilities of a wide range of asset protection solutions that includes enabling data from throughout the oil & gas value chain to be centralized and used to drive actionable insights that maximize uptime and safety.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition