A.C. Gysbers: About the Author

Refining Metallurgical and Corrosion Expert, Becht

Mr. Gysbers has 45 years of industry experience. He retired from ExxonMobil/Imperial Oil as a Senior Engineering Advisor with worldwide corporate recognition as a materials, corrosion, and inspection specialist. Mr. Gysbers was the initial developer of corporate inspection practices, Risk-Based Inspection (RBI) techniques, data analysis tools, IOWs, and CCDs starting in the early 90s. He has worked extensively in the HF Alkylation corrosion space, leading two JIPs to understand corrosion in these units better. Since 2011, he has provided clients with materials, corrosion, and inspection consulting support, primarily in the petroleum refining industry.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

Part 1 of this series provides a suggested framework for consistently generating a complete inspection continuous history report.

Integrity Operating Windows (IOWs) have a subset of operating variables that are important for degradation monitoring, but may not have direct operational controls. Per API RP 584 Integrity Operating Windows, these are known as IOW Informational Limits, which are often neglected or misunderstood by operations or technical personnel within a plant.

This article addresses a debate mechanical integrity professionals in the O&G and Chemical Processing industries periodically have about how thickness data gathered during a thickness monitoring inspection (TMI) should be recorded.

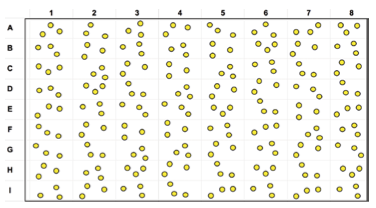

The tubes of heat exchangers (HX), whether for a shell and tube bundle or an airfin, are typically subject to some form of nondestructive examination (NDE) to try and quantify the remaining wall thicknesses and corrosion rates to help a plant to determine remaining life or the need for intervention via re-tubing or replacement of these thin wall components.

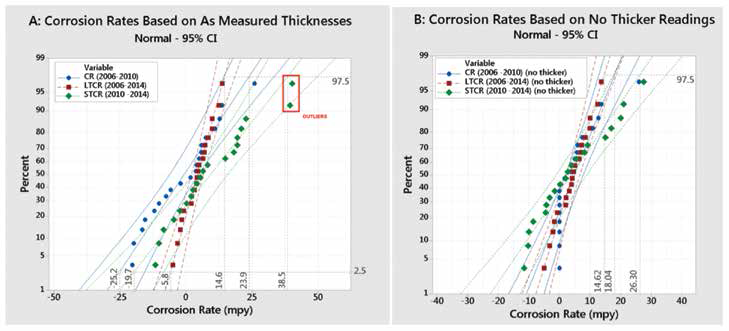

One of the more common inspection monitoring programs for pressure vessels is to perform thickness measurement at Corrosion Monitoring Locations (CMLs) to allow monitoring of minimum thicknesses and provide estimates for corrosion rates. These minimum thicknesses and corrosion rates are critical in supporting risk based inspection techniques or in setting half-life prescriptive re-inspection intervals.

This article is the fifth of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping; Thickness Monitoring Programs for Internal Corrosion.

Piping failures still represent a frustrating and ongoing problem for processing plants. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment...

This article is the third of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping: thickness monitoring programs for internal corrosion. These articles will discuss...

Piping failures still represent a frustrating and ongoing problem for processing plants. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment...

Piping failures still represent a frustrating and ongoing problem for processing plants (example in Figure 1). Failures are commonly reported and contribute to large losses. As well per the author’s experience, piping still represents the highest...