About Us

Our vision is to make the world reliable. We do this by helping complex process facilities such as refineries, chemical plants, mining facilities, and water treatment plants use their data to make better reliability decisions.

Learn more about Pinnacle »Industry Insights

Sharing our most valuable insights, knowledge, and best practices for the industries we serve. Join our team as we dissect problems as they relate to these industry topics and discuss potential solutions to help facilities increase overall safety, decrease downtime, stay compliant, and optimize cost.

View insights »View all Solutions

With a broad expertise base, we are able to integrate our team’s skill sets to provide comprehensive support, helping our clients mitigate loss of containment or functional failure risks; ensure safety of personnel; optimize costs associated with inspection, maintenance, and total asset spend; and ensure compliance with regulatory standards.

View all solutions »Contact Us

Speak directly with a member of our team to discuss your reliability, integrity or inspection program needs.

Contact us »Pinnacle's Inspectioneering Content

-

January/February 2024 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

January/February 2024 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringThe 12th “Meeting of the Minds” roundtable hosted by Inspectioneering and Pinnacle focused on software advancements and new NDE technologies.

-

November/December 2023 Inspectioneering JournalBy Lewis Makin at Pinnacle

November/December 2023 Inspectioneering JournalBy Lewis Makin at PinnacleIn this article, we’ll discuss the current challenges with turnaround planning and how data-driven modeling can help optimize scope, duration, and intervals.

-

BlogDecember 11, 2023 By Pinnacle

BlogDecember 11, 2023 By PinnacleEmbracing technology alone isn't the answer in industry problem-solving. A synergy of data-driven approaches and human expertise unlocks true potential.

-

BlogOctober 27, 2023 By Andrew Waters at Pinnacle and Vyacheslav Nadvoretskiy, PhD at Pinnacle

BlogOctober 27, 2023 By Andrew Waters at Pinnacle and Vyacheslav Nadvoretskiy, PhD at PinnacleThe authors delve into a crucial data integrity challenge known as 'Suspicious Time Periods,' shedding light on the impact of historical inspection data.

-

September/October 2023 Inspectioneering JournalBy Vyacheslav Nadvoretskiy, PhD at Pinnacle and Andrew Waters at Pinnacle

September/October 2023 Inspectioneering JournalBy Vyacheslav Nadvoretskiy, PhD at Pinnacle and Andrew Waters at PinnacleA discussion of common data challenges and how facilities can leverage data science and statistics to identify and potentially correct suspicious data.

-

July/August 2023 Inspectioneering JournalBy Nathanael Ince at Pinnacle and Michael Wallace at Pinnacle

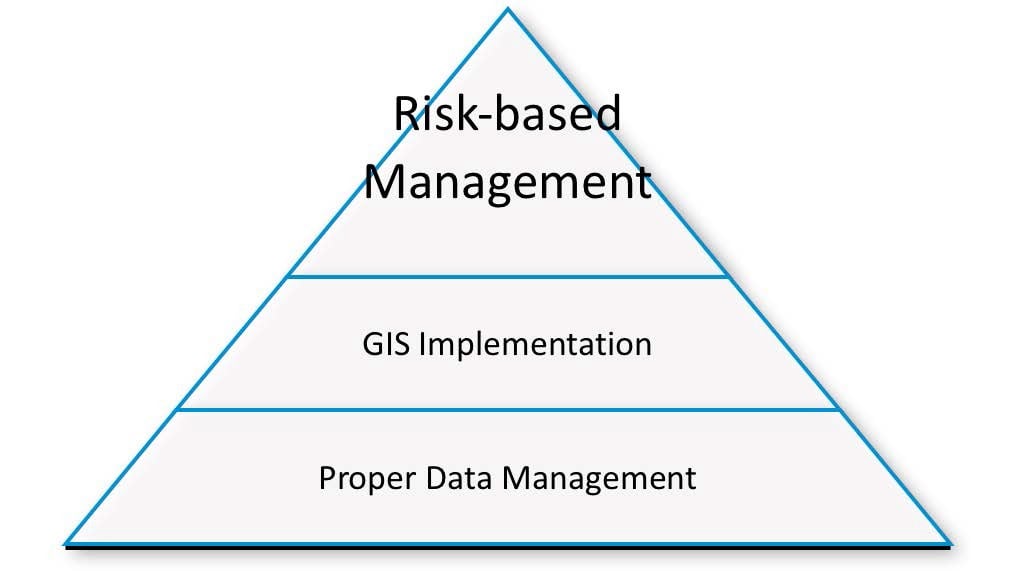

July/August 2023 Inspectioneering JournalBy Nathanael Ince at Pinnacle and Michael Wallace at PinnacleThis article features a discussion of three of the key elements to sustain and improve your mechanical integrity program successfully.

-

July/August 2023 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

July/August 2023 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering and Pinnacle co-hosted the 11th “Meeting of the Minds” roundtable discussion focused on organization capability and competency development.

-

March/April 2023 Inspectioneering JournalBy Lynne Kaley at Pinnacle and Siddharth Sanghavi at Pinnacle

March/April 2023 Inspectioneering JournalBy Lynne Kaley at Pinnacle and Siddharth Sanghavi at PinnacleExplore how more advanced modeling addresses the challenges of quantifying uncertainty and probability of failure to drive valuable inspections.

-

BlogFebruary 27, 2023 By Pinnacle

BlogFebruary 27, 2023 By PinnacleMaintaining the longevity and success of a reliability program requires evergreening, a continuous effort to keep processes up-to-date and relevant.

-

January/February 2023 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

January/February 2023 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringThe focus of the 10th "Meeting of the Minds” roundtable discussion was on data validation and the importance of having consistent definitions of “good data.”

-

November/December 2022 Inspectioneering JournalBy Siddharth Sanghavi at Pinnacle

November/December 2022 Inspectioneering JournalBy Siddharth Sanghavi at PinnacleThis article discusses two use cases of how advanced visual data capture and image analytics can be used across multiple industries to drive better reliability decisions.

-

September/October 2022 Inspectioneering JournalBy Andrew Waters at Pinnacle and Fred Addington at Pinnacle

September/October 2022 Inspectioneering JournalBy Andrew Waters at Pinnacle and Fred Addington at PinnacleWhile data science has the power to revolutionize the reliability industry, it will only do so with strong guidance from SMEs. This combination enables facilities to develop solutions to challenges based on each method’s unique strengths.

-

July/August 2022 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

July/August 2022 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringEarlier this year, Inspectioneering and Pinnacle co-hosted their 9th “Meeting of the Minds” roundtable discussion with a select group of leading MI experts. This year's focus was on data collection, data organization, and data analysis.

-

BlogJune 13, 2022 By Pinnacle

BlogJune 13, 2022 By PinnacleThe addition of data science into traditional reliability methods allows models to evolve continually and learn, preventing results from becoming stagnant.

-

BlogMay 27, 2022 By Pinnacle

BlogMay 27, 2022 By PinnacleThis blog will dive into the “next steps” of maximizing RBI programs, specifically how to better quantify the value of inspections and improve inspection handling.

-

March/April 2022 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at Pinnacle

March/April 2022 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at PinnacleThis study found that a machine learning model was able to predict degradation rates for a hydrocracker unit more accurately and with a smaller margin of error compared to current industry practices.

-

January/February 2022 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

January/February 2022 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering and Pinnacle co-hosted the 8th bi-annual Meeting of the Minds with a select group of mechanical integrity experts from across the industry. The meeting focused on major projects in equipment integrity and reliability.

-

November/December 2021 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at Pinnacle

November/December 2021 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at PinnacleThis article is Part 2 in a series discussing condition monitoring optimization where statistical inference techniques on the measured data can be utilized to provide reasonable expectations regarding the true extent of damage on the asset.

-

September/October 2021 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at Pinnacle

September/October 2021 Inspectioneering JournalBy Andrew Waters at Pinnacle and Ryan Myers at PinnacleCondition monitoring optimization goes beyond traditional CML optimization, which is often limited in the breadth of analysis, or can overemphasize a subset of the overall objective.

-

September/October 2021 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

September/October 2021 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering and Pinnacle co-hosted the 7th bi-annual Meeting of the Minds with a select group of mechanical integrity experts from across the industry. The meeting focused on piping RBI and the challenges operators are facing implementing it.

-

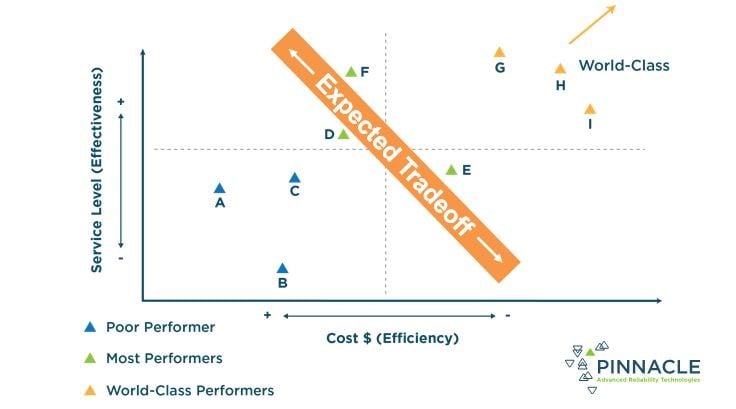

Utilizing Quantitative Reliability Optimization to Better Drive Facility-Wide Reliability and Maintenance Budgets

-

March/April 2021 Inspectioneering JournalBy Sean Rosier at Pinnacle

March/April 2021 Inspectioneering JournalBy Sean Rosier at PinnacleThe manner by which reliability is achieved is experiencing a much-needed paradigm shift in the way it uses data. In this article, we’ll explain how you can leverage this industry shift to implement data-driven reliability at your facility.

-

July/August 2020 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

July/August 2020 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering and Pinnacle co-hosted their 6th bi-annual Meeting of the Minds roundtable discussion earlier this year. This meeting’s focus was on how Covid-19 and the decline in oil prices have affected MI programs across the industry.

-

May/June 2020 Inspectioneering JournalBy Lewis Makin at Pinnacle

May/June 2020 Inspectioneering JournalBy Lewis Makin at PinnacleDespite the recent challenges that the oil and gas industry has faced over the past couple of months, facilities have the unique opportunity to embrace change in company culture, build data-driven processes, and focus on measuring value.

-

January/February 2020 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

January/February 2020 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering and PinnacleART co-hosted their 5th Meeting of the Minds roundtable last November in Atlanta. This meeting’s focus was on notable technologies and how they are changing the MI landscape.

-

November/December 2019 Inspectioneering JournalBy Ryan Myers at Pinnacle and Sean Rosier at Pinnacle

November/December 2019 Inspectioneering JournalBy Ryan Myers at Pinnacle and Sean Rosier at PinnacleToday's operators are implementing a myriad of Mechanical Integrity and Reliability programs to realize greater results from their facilities. However, for each of these programs to be effective, they must be fueled by quality and up-to-date data.

-

BlogOctober 17, 2019 By Pinnacle

BlogOctober 17, 2019 By PinnacleHere is four-step process for developing effective and efficient piping management strategies that can help optimize costs, refocus resources, and reduce risk.

-

May/June 2019 Inspectioneering JournalBy Kate Roberts at Pinnacle and Jarrod White at Pinnacle

May/June 2019 Inspectioneering JournalBy Kate Roberts at Pinnacle and Jarrod White at PinnacleCCDs are critical components of a well-maintained MI program and encompass all necessary and relevant MI information for a given process unit. This article defines the value of having CCDs and addresses how to effectively develop and implement them.

-

May/June 2019 Inspectioneering JournalBy Nick Schmoyer at Inspectioneering

May/June 2019 Inspectioneering JournalBy Nick Schmoyer at InspectioneeringInspectioneering and PinnacleART recently hosted a roundtable discussion for a select group of mechanical integrity experts to discuss strategies for managing corrosion under insulation and corrosion under pipe supports, a.k.a. touch point corrosion.

-

BlogMay 14, 2019 By Pinnacle

BlogMay 14, 2019 By PinnacleThis blog will walk through practical steps for managing IOWS and will demonstrate what successful IOW management can look like.

-

Realized Benefits from RBI Implementation - A Recap of the Fall 2018 Meeting of the Minds Roundtable Discussion

November/December 2018 Inspectioneering JournalBy Nick Schmoyer at Inspectioneering

November/December 2018 Inspectioneering JournalBy Nick Schmoyer at InspectioneeringInspectioneering and PinnacleART hosted a roundtable discussion for a select group of mechanical integrity and reliability experts to explore whether or not operators are realizing actual benefits from implementing RBI at their facilities.

-

November/December 2018 Inspectioneering JournalBy John Campo at Pinnacle

November/December 2018 Inspectioneering JournalBy John Campo at PinnacleThis article walks you through a three-step approach, while providing different scenarios, for identifying and proving the value of reliability improvement initiatives.

-

Making the Leap to Upgrade Your Software – A Follow-up to Achieving the Full Potential of Asset Performance Management Applications

July/August 2018 Inspectioneering JournalBy Brian Maslar at Amplify Technology Solutions, Pete Ankner at Amplify Technology Solutions, and Stephen Flory at Pinnacle

July/August 2018 Inspectioneering JournalBy Brian Maslar at Amplify Technology Solutions, Pete Ankner at Amplify Technology Solutions, and Stephen Flory at PinnacleThis article discusses Asset Performance Management (APM) software implementation strategies and the challenges owners face when upgrading their software to the newest version.

-

March/April 2018 Inspectioneering JournalBy Cesar Espinoza at Pinnacle and Sudhakar Mahajanam at Pinnacle

March/April 2018 Inspectioneering JournalBy Cesar Espinoza at Pinnacle and Sudhakar Mahajanam at PinnacleAs RBI continues to proliferate across industry, there are still those that are reluctant to transition from a time-based to risk-based inspection approach - especially in the upstream oil & gas business. These 4 benefits might help to lessen the...

-

March/April 2018 Inspectioneering JournalBy Tyler Alvarado at Inspectioneering

March/April 2018 Inspectioneering JournalBy Tyler Alvarado at InspectioneeringLast November, Inspectioneering and PinnacleART hosted a roundtable discussion for a select group of leading mechanical integrity experts. This forum explored how the MI field will have to prepare for the impending loss of knowledge resulting from...

-

November/December 2017 Inspectioneering JournalBy Stephen Flory at Pinnacle

November/December 2017 Inspectioneering JournalBy Stephen Flory at PinnacleAPM implementation is anything but a pain-free process. Blame tends to fall on vendors, but there are oftentimes activities that do not get completed that tend to have a larger effect on the success of implementation. This article addresses some of...

-

May/June 2017 Inspectioneering JournalBy Ryan Myers at Pinnacle and Brian Marino at Pinnacle

May/June 2017 Inspectioneering JournalBy Ryan Myers at Pinnacle and Brian Marino at PinnacleEffective condition monitoring location selection is a key component of a best-in-class mechanical integrity program. Learn how moving beyond traditional qualitative approaches to optimized CML selection can reduce risk and maximize the value of...

-

November/December 2016 Inspectioneering JournalBy Adam Gardner at Pinnacle

November/December 2016 Inspectioneering JournalBy Adam Gardner at PinnacleBeyond the financial hits, undetected degradation from corrosion can also lead to critical safety risks. To effectively manage mechanical integrity, organizations need reliable methods of identifying the current states of corrosion occurring within...

-

Program Evergreening and Sustainability Assistance is Key to Establishing Successful Integrity and Reliability Programs

September/October 2016 Inspectioneering JournalBy Kevin Birkby at Pinnacle

September/October 2016 Inspectioneering JournalBy Kevin Birkby at PinnacleIntegrity and reliability personnel at processing facilities are no strangers to initiatives to improve processes in the pursuit of establishing best-in-class reliability programs. It is common practice for operators to enlist help from third...

-

May/June 2016 Inspectioneering JournalBy Jeffrey Foushee at Pinnacle and Ryan Myers at Pinnacle

May/June 2016 Inspectioneering JournalBy Jeffrey Foushee at Pinnacle and Ryan Myers at PinnacleData, in pure form, consists of raw, unorganized facts that need to be processed. Data can be found in databases, documents, drawings, reports, spreadsheets, and numerous other sources. Having data on hand is useful, however, it’s often...

-

March/April 2016 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

March/April 2016 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering recently had an opportunity to sit down with Walt Sanford, President and COO of Pinnacle Advanced Reliability Technologies, and discuss what Reliability means to his clients and others in our industry. We hope you find the exchange...

-

Keys to Success: How to Design and Use Effective Reliability and Integrity Program Assessments to Drive Sustainable Improvements

January/February 2016 Inspectioneering JournalBy Walt Sanford at Pinnacle and Mauricio Olivares at Pinnacle

January/February 2016 Inspectioneering JournalBy Walt Sanford at Pinnacle and Mauricio Olivares at PinnacleEquipment integrity and reliability programs are essential for refinery and chemical facility operators. The processes of the programs are developed to ensure safety, optimize component life cycles, and promote smooth and economical operations.

-

November/December 2015 Inspectioneering JournalBy Walt Sanford at Pinnacle

November/December 2015 Inspectioneering JournalBy Walt Sanford at PinnacleMaximizing return on investment of physical assets, while at the same time operating safely and in an environmentally responsible manner is now more critical than ever for organizations within the heavy process industries.

-

September/October 2015 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

September/October 2015 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringInspectioneering recently had the opportunity to sit down with Texas Railroad Commissioner Ryan Sitton and discuss the evolution of reliability in the oil and gas industry.

-

September/October 2015 Inspectioneering JournalBy Brad Moore at Pinnacle

September/October 2015 Inspectioneering JournalBy Brad Moore at PinnacleOperators in all industries are trying to increase equipment availability, yet oftentimes critical process equipment is not available due to planned or unplanned maintenance. To increase equipment availability, steps must be taken to reduce...

-

A New Trend for Pipeline Integrity Management: How GIS and Risk-Based Asset Management (RBA) Integration Can Improve Pipeline Management

-

March/April 2015 Inspectioneering JournalBy Walt Sanford at Pinnacle

March/April 2015 Inspectioneering JournalBy Walt Sanford at PinnacleToday, many managers are finding that they can address the reliability of all types of assets by combining RBI and Reliability Centered Maintenance (RCM) processes together into one comprehensive reliability management process.

-

November/December 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Jeannie Beth Richey at Sasol North America, Inc., and Josh Yoakam at Holly Frontier Companies

November/December 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Jeannie Beth Richey at Sasol North America, Inc., and Josh Yoakam at Holly Frontier CompaniesThe role of an API inspector is rapidly changing. Necessary skills for success have transformed as technology, standardization, and regulations have become part of the way of life.

-

March/April 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Gerrit Buchheim, P.E. at Becht, and Josh Yoakam at Holly Frontier Companies

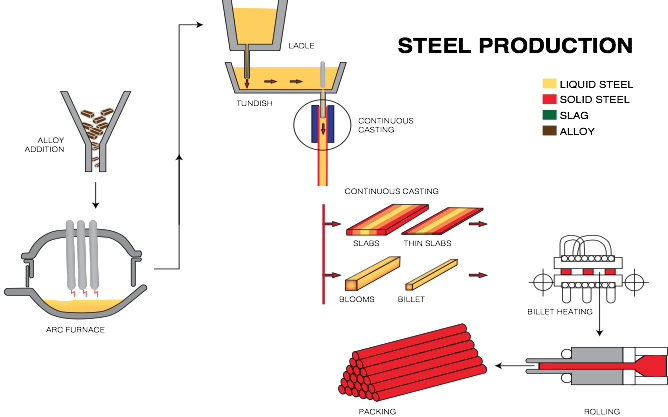

March/April 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Gerrit Buchheim, P.E. at Becht, and Josh Yoakam at Holly Frontier CompaniesHigh temperature sulfidation is probably the most well- known corrosion mechanism in the oil refining industry because it occurs in large sections of the refinery.

-

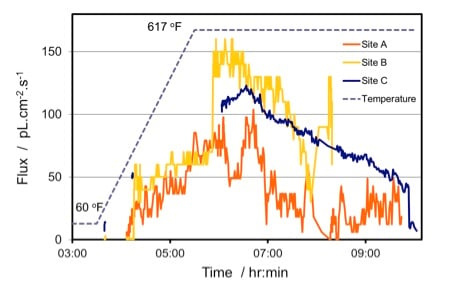

January/February 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Josh Yoakam at Holly Frontier Companies, and Frank Dean at Ion Science, Ltd.

January/February 2014 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services, Josh Yoakam at Holly Frontier Companies, and Frank Dean at Ion Science, Ltd.This is the second of two articles published in Inspectioneering Journal discussing the value of hydrogen bake-outs. Our first article was published in the May/June 2013 issue and received a great response from the Inspectioneering community. In...

-

September/October 2013 Inspectioneering JournalBy Jeremiah Wooten at Inspectioneering

September/October 2013 Inspectioneering JournalBy Jeremiah Wooten at InspectioneeringEarlier this year, our friends at Pinnacle Asset Integrity Services hosted a webinar entitled Mechanical Integrity Assessment: Why Bother? The broadcast included discussions on the history and value of asset integrity programs, as well as the...

-

July/August 2013 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services

July/August 2013 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical ServicesWho at your facility owns injection point hardware? Typically, injection point hardware falls into the Gray Zone.

-

May/June 2013 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical Services

May/June 2013 Inspectioneering JournalBy Marc McConnell, P.E. at Pro-Surve Technical ServicesWith 30 years of refinery experience, I have been through many turnarounds and been involved with a lot of repairs. When I started in the business, we would have inspectors that “owned” their specific pieces of equipment.

Pinnacle has released its Economics of Reliability report for the refining industry, highlighting the importance of reliability as refiners face pressure to expand capacity to meet increased demand for petroleum products

Pinnacle, a reliability data analytics company, released its Economics of Reliability report for the midstream oil & gas industry today.

Pinnacle released its Economics of Reliability Report for the global chemicals industry today. This report is the fourth installment of Pinnacle’s Economics of Reliability series.

Pinnacle, the world’s largest reliability analytics company, and Cognite, a global leader in industrial software innovation, have strategically partnered to accelerate and scale the deployment of the world’s first live reliability digital twin.

Pinnacle introduces an improved approach to reliability modeling, called Quantitative Reliability Optimization (QRO). This new approach streamlines current reliability methodologies into a single, comprehensive analysis.

Pinnacle, the world’s leading provider of data-driven reliability and integrity programs, announced it has acquired Trinity Bridge, LLC, a consulting company specializing in RBI programs.

The report is the first of its kind, and the first in a series of reports that explore the impact reliability has on various global industries including the oil and gas, chemical, wastewater, and other industrial processing industries.

PinnacleART, now Pinnacle, leaders in the industrial reliability and mechanical integrity market, is doubling down and focusing on data-driven reliability to help its clients reduce risks and maximize overall productivity.

PinnacleART is proud to announce that Ralph Stevens, principal reliability consultant, recently earned the distinguished Certified Asset Management Assessor (CAMA) certification.

Connected Field is a cloud-based platform that manages field activities by integrating real-time field data from a mobile application with a cloud-based management suite.

As CFO, Andrew Susman will serve as the financial leader responsible for planning and executing financial strategies to support the rapid growth of the company.

PinnacleART and Metegrity, Inc. have formed a strategic partnership to improve the mechanical integrity program of a natural gas service provider’s operations in the southwest region of the United States.

PinnacleART has strategically partnered with Solomon Associates to build comprehensive asset assessments for facilities in the energy and chemical industries.

PinnacleART, a global leader in designing, implementing, and maintaining asset reliability and integrity programs, has added rope access services to its repertoire of inspection services.

Last November in Dallas, TX, Inspectioneering and PinnacleART hosted a select group of leading industry experts in mechanical integrity for an informal discussion of some of the key challenges facing the industry today. The main theme for this...

PinnacleART is now an official Implementation Service Provider (ISP) for the aspenONE® Asset Performance Management (APM) software suite from Aspen Technology, Inc. PinnacleART will utilize aspenONE APM solutions to measure, optimize and maximize...

Pinnacle Advanced Reliability Technologies (PinnacleART) has been recognized by Inc. Magazine as one of the fastest growing private companies in the United States. This list represents 5000 of the most successful companies within the American...

Pinnacle Advanced Reliability Technologies (PinnacleART) has announced the expansion of its advanced nondestructive testing (NDT) inspection team, which now employs two of only 41 American Petroleum Institute (API) Qualification of Ultrasonic Sizing...

-

Sponsored Webinar Replay

Sponsored Webinar ReplayLearn how facilities can utilize their process data to bring MI and operations teams together, optimize turnaround strategy, and reduce risks and costs.

-

Sponsored Webinar Replay

Sponsored Webinar ReplayThis webinar explores how integrating data science methodologies can transform this process and avoid dismissing valuable insights.

-

Sponsored Webinar Replay

Sponsored Webinar ReplayInspectioneering teams up with Pinnacle to bring you "A Data-Driven Approach to Sustaining and Improving Your MI Program."

-

Leveraging Data Science and Machine Learning to Improve Your Reliability and Mechanical Integrity Programs

-

Sponsored Webinar Replay

Sponsored Webinar ReplayInspectioneering teams up with Pinnacle to bring you "4 Ways to Get More from Your RBI Program," a one hour webinar presented by Ryan Myers and Lynne Kaley.

-

CML Optimization Pilot Project Helps Refinery Reduce Risk and Identify Minimum Reduced Inspection Spend of $384K

-

Sponsored Webinar Replay

Sponsored Webinar Replay60-minute webinar presented by PinnacleART on the evolution of inspection and mechanical integrity programs in the refining and process industries.