Introduction

Operators in all industries are trying to increase equipment availability – the probability that an asset (or system) will be operational (either running or able to be run) at any given time. Yet oftentimes, critical process equipment is not available due to planned or unplanned maintenance. To increase equipment availability, steps must be taken to reduce downtime.

One way to reduce downtime in a refining or petrochemical facility is to ensure that spare parts are organized and available in the event repairs are needed. The activities included in spare parts optimization include the following:

-

Identifying the potential challenges or roadblocks,

-

Spare parts identification and association with the appropriate equipment,

-

Determining the appropriate stocking decision methods (quantitative or qualitative), and

-

Setting minimum stock quantities.

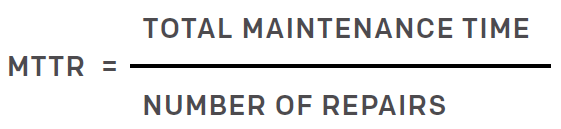

A standard calculation generally used by equipment operators or managers throughout the process industries is Mean Time to Repair (MTTR).

The formula for MTTR is listed below.

One of the factors that can affect MTTR is the availability of spare parts needed to complete a maintenance activity. A top priority for facility management is keeping costs low while maintaining optimal uptime. However, accomplishing this goal can be challenging when equipment breaks down unexpectedly. Even the replacement of a minor part on a piece of equipment can turn into a major incident if the appropriate spare part is not readily available.

The intent of this article is to discuss various methods used to identify spare parts and recommend stocking quantities to help minimize the MTTR, while maintaining a focus on cost optimization of the inventory. We will consider the issue of incorporating spare parts for a new capital project into an existing inventory system. This scenario could be the installation of a new unit at a refinery or a new offshore production platform that shares a warehouse with several other platforms.

Project Challenges

Incorporating these new parts can uncover issues with current spare parts organization and management. It can also reveal inefficient processes leading to inaccessible and poorly identified spare parts inventory.

During a recent project, a facility faced several challenges, including the duplication of spare parts that were recommended for various equipment units, the inability to locate spare parts for new equipment in the existing inventory, and the inability to confirm whether multiple inventories of a similar part were actually the same part. These inefficiencies led to unnecessary delays and in the end, lost profits.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.