LRUT for the in-service surveying of metal loss in pipelines and piping was introduced by Plant Integrity (Pi) Ltd in the form of the Teletest® in 1998. Pi is a subsidiary of TWI (formerly The Welding Institute) and provides a commercial outlet for TWI’s technologies.

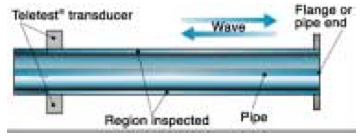

The impetus for the development of LRUT is that ultrasonic thickness checks for corrosion, erosion, etc. are localised, in that they only measure the thickness of the area under the UT transducer. The operation of the LRUT technique is shown schematically in Fig.1. Teletest® uses low frequency guided ultrasound travelling along the pipe providing 100% coverage of the pipe wall.

Up to 350 metres of pipework can be inspected from a single test point (using a battery- or mains-power supply). LRUT reduces the costs of gaining access and avoiding extensive removal of insulation (where present). The whole pipe wall is tested, achieving a 100% examination (including areas such as at clamps, and sleeved or buried pipes).

Continuous Development

Over the past decade, the development of LRUT has been funded through a variety of sources including most recently, the Pipeline Research Council International, for the application of LRUT to large gas transmission pipelines.

The equipment can now generate any of the three main long-range wave types (longitudinal, torsional and flexural). It uses phased-array technology making it possible to focus ultrasound at any point both along and around the pipe). The inflatable collars and multi-mode transducer modules increase its high temperature capability to 160°C.

Inspection Sensitivity

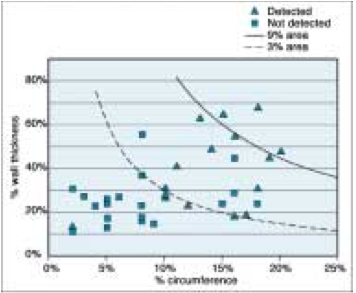

The earliest work showed that the smallest area of metal loss which LRUT can detect is approximately 3% of the pipe wall cross-section. The reporting level which is normally used is a signal amplitude equivalent to 9% area, to ensure that false call rates are kept to an acceptable level. These thresholds were verified through ‘blind trials’ without knowledge of any defects and the results were independently evaluated.

Figure 3 shows the results from the Teletest® technique on 36 individual defects. The plot is in terms of depth and circumferential extent of the defects and indicates whether each was detected or not. The lines representing 3% and 9% defect area are also included. The data show the classic probability of detection characteristics, with an increasing likelihood of detection above the 3% level. All flaws at or greater than the 9% reporting level were detected.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.