Magnetic Flux Leakage (MFL) is an advanced nondestructive testing (NDT) technique commonly used in the oil & gas and chemical processing industries to inspect for wall loss and sharp defects such as pitting, grooving, and circumferential cracks in ferromagnetic materials (most commonly pipelines and storage tanks).

History and Development

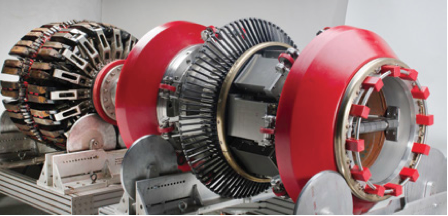

The practice of inspecting pipelines using “smart” inspection devices (also known as a smart pig) came about in 1964 when the first in-line inspection (ILI) tool was equipped with MFL inspection technology. During the 1970s, the first “high-resolution” pigs were developed. These tools were capable of detecting pipeline defects more accurately and reliably. During the 1980s, more MFL ILI technologies emerged in the form of ultrasonic wall thickness measurement tools. During the 1990s, ultrasonic crack detection and circumferential MFL tools capable of detecting narrow axially oriented defects (including open cracks) were developed. During the 2000s, technologies improved in ways that made them capable of accurately detecting and sizing a more diverse range of pipeline anomalies.

Methodology

Magnetic flux leakage uses electromagnetism to inspect for flaws or material degradation in steel components and structures. MFL utilizes magnets to temporarily magnetize the part, and if flaws are present, the magnetic field created will show distortions, signaling the presence of things like corrosion, pitting, and wall loss. MFL is useful because it's highly portable and an effective technique for detecting subsurface cracks. On the other hand, if the defects are too deep in the material, MFL may not be able to detect them.

Magnetic flux leakage is not a quantitative NDT method because it only reports areas where material loss is detected. As a follow-up, other NDT methods like ultrasonic thickness testing may be necessary to verify the MFL findings and determine the severity and extent of any material loss detected.

Industry Applications

Magnetic flux leakage is commonly used for inspecting pipelines and storage tanks in the oil & gas industry; however, the technique can be applied to assets in other industrial sectors. In fact, MFL is the oldest and most commonly used ILI technique for pipelines due to its ability for reliably detecting—while the pipelines are in service—internal and external metal loss due to corrosion. MFL is also widely used for detecting flaws and corrosion in above ground storage tank floors.

References

- Ellinger, M., 2017, “A History of In-Line Inspection Tools,” Inspectioneering Journal, The Woodlands, Texas.

Related Topics

- Acoustic Emission Testing (AET)

- Advanced Ultrasonic Backscatter Technique (AUBT)

- Eddy Current Testing (ECT)

- Electro Magnetic Acoustic Transducers (EMAT)

- Guided Wave Ultrasonics (GWUT)

- Infrared Inspection

- Liquid Penetrant Examination (LPE)

- Magnetic Particle Testing (MPT)

- Meandering Winding Magnetometer Array (MWMA)

- Pulsed Eddy Current (PEC)

- Radiography

- Remote Field Eddy Current (RFEC)

- Ultrasonic Testing (UT)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition