This paper describes the use of a UT fixture for detection of stress corrosion cracking in ferrous heat exchanger tube-to-tubesheet welds and external tube corrosion or pitting near the tubesheets including crevice OD corrosion of the tube in the tubesheets.

A study of means for locating the source of exchanger shell to tube-side leaks in the water treatment section in a fertilizer plant (1) was undertaken. An effective UT inspection technique was developed, as a result.

The shell-side liquid stream in this process normally contained a low level of caustic. Operating upsets caused an increase in caustic concentration sufficient to subject the ferritic tube welds to stress corrosion. Daily lab tests were routinely made of the tube-side stream to measure chloride concentration. These tests required 10 hours before results were known. In this period, if an undetected leak developed, unacceptable contamination would occur. In addition, two days of downtime were required to clean and decontaminate the exchanger, find the leak and plug the tube.

Locations where leaks were found indicated that more than 90% occurred in the region of the tube/tube sheet. Further work including leak tests and visual inspections pinpointed the cause as stress corrosion cracks in the tube-to-tubesheet welds.

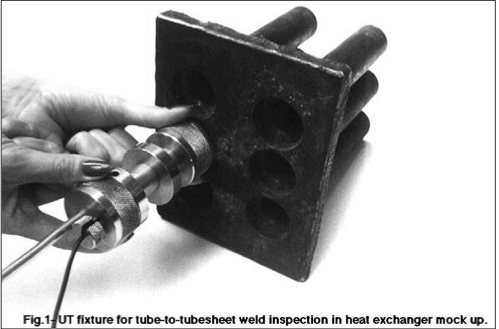

Under these circumstances, and after investigation of promising NDT solutions, a feasibility study indicated that a portable UT fixture could be designed for in-situ, field application using a conventional pulse echo ultrasonic flaw detector.

This design includes a captive, water coupled transducer configuration which permits precise, reproducible “aiming” of the UT beam and minimizes reception of undesired echoes.

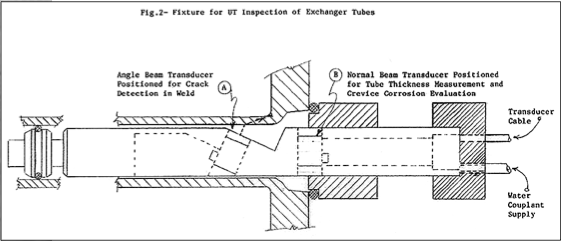

As indicated, the incident UT beam in water produces a refracted shear wave in the carbon steel tube/weld region. This configuration gives a relatively “clean” flaw echo and minimizes undesired backscatter from the tube and weld surfaces. Tests indicated that use of a 5 MHz transducer permitted detection of cracks equivalent to the response from a 1/32” diameter flat bottom hole.

In addition to inspecting tube-to-tubesheet welds:

The fixture can be modified to evaluate external corrosion and pitting in the tube wall within a distance of up to 12” from the tube sheet.

In conventional tubes rolled into the tubesheet, the tube OD can be checked for crevice corrosion adjacent to rolled region in the tubesheet.

These capabilities are illustrated at the transducer angle beam and normal beam positions (A) and (B) in Fig. 2. In these examples the transducer carrier is repositioned so that the normal beam transducer is opposite the respective points of interest.

The above example(1) was designed for use in exchangers tubed with ferritic tubes, 31.8 mm (1.272”) x 3.6 (0.144”) mm wall. Other fixtures(2) have been designed and made to accommodate tubes ranging from 1” up to 1 1/2” in OD.

References

- This plant formerly operated by Exxon Chemical Co., located in Redwater, Alberta, Canada

- Rohm & Haas, Inc., Deer Park, Texas.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.