Eddy Current Testing (ECT) is an electromagnetic testing method for nondestructive testing (NDT) of conductive materials. This method can be used in several applications such as crack detection, measuring metal thickness, detecting metal thinning, determining coating thickness, and measuring electrical conductivity and magnetic permeability.

History & Development

The principles of eddy current testing were first laid out in 1831, when Michael Faraday discovered electromagnetic induction. Eight years later, these basic principles led to a new discovery when researchers learned that the properties of a coil would change when placed in contact with metals of different connectivity and permeability. It wasn't until World War II that these principles found practical use though.

ECT Methodology

Eddy current testing is based on the relationship between electricity and magnetism (electromagnetism). An eddy current (EC) system is composed of three fundamental components: the flaw detector instrument, software, and the probe (test coil housing). The test coils are composed of a tightly wound wire (coil) in various configurations and operate on Oersted’s theory of electromagnetism where a magnetic field develops from the electric current through a conductor. Specifically, an alternating current flows through the wire coil and generates an oscillating magnetic field. When the probe comes into contact with a conductive test specimen, a circular flow of electrons, called eddy currents, are induced into the part, which makes its own magnetic field. The part’s localized magnetic field interferes with the coil in a principle known as mutual inductance.

The operational basis for EC technology is Faraday’s law of electromagnetic induction, which states that the relative motion between a magnetic field and conductor causes voltage in the conductor. If the energized coil comes in contact with a conductive material, it impacts the electrical impedance of the coil, and the combined signal is displayed on the instrument’s screen. When the coil passes over a flaw or indication, the instrument records the change in the impedance amplitude and phase angle, presenting instant feedback to the qualified inspector for assessing the indication.

The distance from the probe to the part is called “lift-off.” If the lift-off is zeroed (nulled), it can be a valuable feature that enables inspectors to ignore the gap (paint to base material), enabling direct material inspection without paint removal. Using this method to measure coating thickness before performing other NDT methods, like magnetic particle testing, is an option often called out in industry codes. An additional element to an EC inspection system is that the AC field couples the coil to the part without the need for materials like couplant (often necessary for ultrasonic testing). This enables the inspection to be performed without additional materials, without post-inspection cleaning, and without stripping off the coating on the component being tested.

EC can measure the volumetric impact of a disruption and display comparative depth sizing. When precisely calibrated for material and sensitivity, indications can be accurately sized using conventional EC. The amplitude and impedance are displayed on the flaw detector, enabling a qualified inspector to assess the location and severity of the indication. This file can be easily saved for reporting, post-processing, and additional verification. Calibrating samples of known damage depths, representative of the test subject, is important for accurate crack depth sizing. Depth sizing using EC methods is highly dependent upon material, thickness, and crack depth. Depths using EC data are typically used for screening. The calibration is done to help ensure that the desired levels of precision can be achieved.

ECT Advantages & Limitations

Advantages of eddy current testing include:

- ECT is sensitive to and can detect small cracks and other defects

- ECT equipment is portable

- Minimum part preparation is required

- The test probe does not need be in contact of the part

- ECT can be used to inspect complex shapes and sizes of conductive materials

Certain limitations of eddy current testing include:

- Slow speed and limited coverage area

- ECT can only inspect conductive materials

- The surface must be accessible to the probe

- High skill and training is required compared to other techniques

- The surface’s finish and roughness may interfere

- ECT penetration depth is limited

Other ECT Techniques

To circumvent some of the shortcomings of conventional eddy current testing, other effective techniques have been developed.

Pulsed Eddy Current

Pulsed Eddy Current (PEC) works by using the principle of electromagnetic induction. When applying step function voltage to a conductor, a magnetic field develops around it. This field changes in intensity as the current alternates. If brought close to the first field, another conductor will have a current induced in it as well. If there are any flaws in this material then the EC will distort. In the case of PEC, the first conductor is an EC probe; the second is the test material.

The main advantage of PEC over conventional EC is that it contains a continuum of frequencies. Because of this, it is possible to measure the electromagnetic response to several different frequencies with just a single step, and information from a range of depths can be obtained all at once.

PEC can be done without need for contact with the surface of the material. It can therefore be useful in situations where an object’s surface is rough or inaccessible. Additionally, this method doesn’t require surface preparation or removing any insulation, making it a relatively quick and cost-effective solution for corrosion detection.

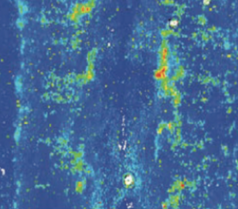

Eddy Current Array

Eddy Current Array (ECA) involves multiple EC coils placed side by side in the same assembly. In conventional eddy current testing, the probe is rastered to enable full area coverage and may miss some areas. With ECA’s overlapping/multi-coil design, users can inspect a larger coverage area more quickly (normally about 32 times the coil coverage). Each coil in the probe produces a signal, the strength of which depends on the phase and amplitude of the object the probe is placed over. This signal can be measured and the data recorded. This data can then be referenced to an encoded position and time and represented visually as a C-scan image.

ECA is capable of reproducing the flaw detection techniques of most other EC methods. However, this method has several distinct advantages, such as:

- Being able to scan a larger area at one time while maintaining a high resolution,

- A lesser need for complex robotics to actually move the probe,

- Improved flaw detection due to the C-scan imaging, and

- Complex shapes can be inspected using this method because the probes can be customized to the profile of the part being inspected.

Both ECA and PEC can be utilized for a number of industry applications. They can be used both for measuring the thickness of steels and detecting corrosion. Moreover, they can be used on materials as diverse as vessels, columns, storage tanks and spheres, piping systems, and even structural applications.

References

- https://www.nde-ed.org/NDETechniques/EddyCurrent/Applications/breakingcracks.xhtml

- https://www.nde-ed.org/NDETechniques/EddyCurrent/Introduction/IntroductiontoET.xhtml

- https://inspectioneering.com/journal/2016-10-27/5733/detecting-and-quantifying-cracks-using-eddy-current-array

Related Topics

- Acoustic Emission Testing (AET)

- Advanced Ultrasonic Backscatter Technique (AUBT)

- Electro Magnetic Acoustic Transducers (EMAT)

- Guided Wave Ultrasonics (GWUT)

- Infrared Inspection

- Liquid Penetrant Examination (LPE)

- Magnetic Flux Leakage (MFL)

- Magnetic Particle Testing (MPT)

- Meandering Winding Magnetometer Array (MWMA)

- Pulsed Eddy Current (PEC)

- Radiography

- Remote Field Eddy Current (RFEC)

- Ultrasonic Testing (UT)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition