Richard D. Roberts: About the Author

Quest Integrity Group

Rich Roberts began his career in the oilfields of Alaska at Arco Petroleum in 1985, where he was involved in a massive corrosion monitoring and prevention program encompassing critical assets such as pipelines, pressure vessels, tanks and well heads. After departing Alaska in 1992, Mr. Roberts helped implement specialized NDE/T division start-ups for various engineering and service companies within North America, such as ABB/Amdata, Combustion Engineering and CTI/Tuboscope. In 1995, Quest Integrated recruited Mr. Roberts to establish a Field Services Division charged with developing and applying its proprietary NDE platforms, LOTIS® and FTIS. When Quest Integrated's Field Service Division and TruTec Services merged to create Quest TruTec in 2004, Mr. Roberts assumed leadership for Quest TruTec's Condition Assessment Division. Today at Quest Integrity, Mr. Roberts leads both operations and engineering activities for the Inspection Division and coordinates Refining industry-targeted strategic initiatives. Mr. Roberts received his A.S. in NDE from the University of Alaska and his B.S. in Welding Technology from Ohio State University.

Rich Roberts began his career in the oilfields of Alaska at Arco Petroleum in 1985, where he was involved in a massive corrosion monitoring and prevention program encompassing critical assets such as pipelines, pressure vessels, tanks and well heads. After departing Alaska in 1992, Mr. Roberts helped implement specialized NDE/T division start-ups for various engineering and service companies within North America, such as ABB/Amdata, Combustion Engineering and CTI/Tuboscope. In 1995, Quest Integrated recruited Mr. Roberts to establish a Field Services Division charged with developing and applying its proprietary NDE platforms, LOTIS® and FTIS. When Quest Integrated's Field Service Division and TruTec Services merged to create Quest TruTec in 2004, Mr. Roberts assumed leadership for Quest TruTec's Condition Assessment Division. Today at Quest Integrity, Mr. Roberts leads both operations and engineering activities for the Inspection Division and coordinates Refining industry-targeted strategic initiatives. Mr. Roberts received his A.S. in NDE from the University of Alaska and his B.S. in Welding Technology from Ohio State University.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

Refineries and chemical plants own and operate numerous process heaters (e.g. gas reformers, CCRs, etc.) as part of the standard assets throughout the facilities. Many heater coil configuration designs are flanged at both ends; however, there are also coil designs which contain common headers, linking the individual coil passes together at the inlet, outlet, or even at both ends in some cases.

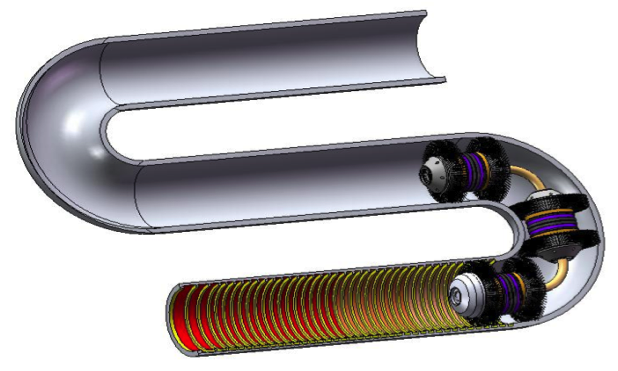

Various fired heater designs in refineries and chemical plants contain common headers (e.g. Arbor coil configurations, CCRs, etc.) as part of their overall serpentine coil design. Accessing the interior of individual coils through the common header is challenging; however, advanced engineering firms and mechanical decoking companies have developed unique common header snorkel delivery systems.

The refining industry has applied ultrasonic-based intelligent pigging to inspect serpentine coils in fired heaters since the 1990s. Today, thousands of serpentine coils in fired heaters are inspected annually at process facilities around the globe.

For years refinery and chemical plant operators have utilized ultrasonic-based intelligent pig technology to inspect coils in convection and radiant sections of fired heaters. This proven technology provides accurate inspection data which allows reliability engineers to make critical decisions about the operation and maintenance of fired heaters. Recent advances have increased the capabilities of these tools and extended these benefits to coker heaters containing 3" (76.2mm) nominal piping size and plug headers with radial inserts.

Part 1 in this 2 parts series laid the technical foundation for the methodology and technology. Part 2 will now demonstrate both through actual applications.

Having the ability to substantially extend tube life in Steam Reformers is essential in maximizing use of capital investments in Methanol, Hydrogen, and Ammonia Plants. With the price of nickel at an all time high, the cost of installing a single reformer tube upwards $20,000 USD.However, in today's highly competitive markets the effect of the unplanned downtime in reducing the plant on-stream factor is far greater than the installed cost of a single reformer tube.

Reliable "intelligent pig technology" is now readily available to the refining industry which can provide quick / comprehensive inspection to both "convection" and "radiant" sections in process furnace piping coils. Both tabular data formats along with 2D / 3D high-resolution color graphics of the test results are immediately produced on site showing tube/pipe wall thinning, bulging, swelling, and ovality.

Steam reformers are an integral part of ammonia, methanol, hydrogen, and gas process plants around the world. THey are one of the highest cost, both in capital and maintenance, pieces of equipment in the plant. Typically, reformers contain several hundred vertically oriented straight tubes, referred to as catalyst tubes. These tubes represent a significant cost for replacement and can be a major source of plant unavailability if unplanned failures occur.

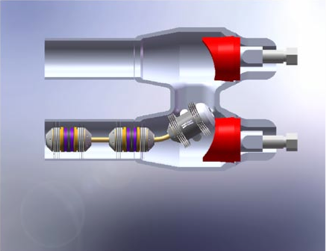

Part 1 included a review of current tube inspection practices in convection and radiant sections of heaters/furnaces in the refining and chemical industries. The authors also presented a new inspection device combining laser image mapping of the internal surface of tubes and ultrasonic thickness mapping.

Furnace tubes in the petrochemical and refining industries lengths' can exceed 2,000 ft., often with multiple serpentine bends. This can make them extremely difficult to inspect using conventional NDE methods. The following inspection tool (FTIS) employs the combined capabilities of high-speed laser and advanced ultrasonic wall thickness measurements and is propelled through the piping via a column of clean water which provides a path for the laser beam, and the coupling for the ultrasonic signals.