Background

Due to the evolution of ultrasonic phased array (UTPA) technologies and increased data processing speed, off-the-shelf phased array instruments are now used to perform high-resolution corrosion inspections in accordance with today’s demanding industry standards. This article highlights the evolution of corrosion monitoring from conventional ultrasonic to ultrasonic phased array manual and automated solutions and their use for both general purposes and complex applications.

Introduction

Manual point thickness measurements using conventional ultrasound (UT) is a widely used technique for monitoring corrosion in many infrastructure applications. Depending upon the nature of the corrosion (e.g. localized, versus generalized and pitting), an inspector typically records the minimum thickness reading within a small area (usually 1 in.2). This however can lead to inconclusive inspection data due to minimal coverage of large areas, operator variability, lack of pitting or localized corrosion detection, and inadequate data reporting and analysis.

Ultrasonic phased array corrosion monitoring systems can be used to inspect large surface areas quickly with high resolution. Typically, a thickness reading is performed every 1 mm2, which represents 500 more sample points than conventional ultrasound. This high resolution makes it possible to detect small, localized indications, such as corrosion pits, and it enables the operator to profile the shape of the corroded area. This helps users to accurately evaluate the severity of corrosion defects and provides information for more accurate characterization of the damage.

Intuitive and affordable phased array instruments are now commercially available. These devices are easy to setup so users can record and archive data for further analysis. Easy-to-read images make interpreting acquisition data fairly straightforward. The data can then be used to perform corrosion assessments according to ASME B31G and other applicable standards.

Ultrasonic Phased Array Tools

Phased array technology is based on the capacity to electronically modify ultrasonic beams generated by a phased array probe that contains multiple small elements. When these elements are excited using different time delays (focal laws), the beams can be steered at different angles, focused at different depths, or multiplexed over the length of a long array, creating the electronic movement of the beam.

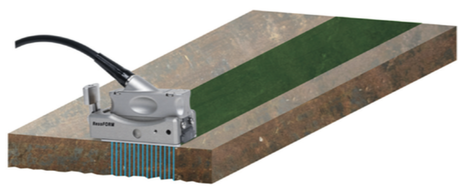

Multiplexing, sometimes called an electronic or linear scan, is used to perform corrosion monitoring. The sensor consists of a long phased array probe, 25 –100 mm(1 – 4 in.) with between 32 and 128 elements. A small group of elements, defined as the active aperture, is activated to generate an ultrasonic beam propagating normal to the interface. This group of elements is then indexed using electronic multiplexing, creating a true physical movement of the ultrasonic beam under the array with an index as small as 1 mm (0.040”). The electronic indexing is performed so fast that a 4 inch (100 mm) line length is covered by the ultrasonic beams in milliseconds. The travel time of these beams is used to determine the component’s thickness at each acquisition point.

Off-the-shelf phased array sensors are available for corrosion monitoring applications. Using phased array probes in direct contact with the component, whether mounted on a hard wedge, a water delay line, or even inside a wheel probe, permits inspectors to cover a large area with high resolution in a very short period of time.

The sensors can be used manually in a free running mode scrubbing the surface of a test piece, attached to an encoder to record position, or mounted on a semi-automated or motorized scanner for optimum productivity.

One of the advantages of using a phased array instrument is the availability of color-coded mapping images (C-scan) of wall thicknesses. This image enables the user to detect zones of anomalies at a glance, for in-depth analysis of the inspected area, as appropriate.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.