Is That The Latest Computer Game?

Piping Inspection Thickness and Corrosion Monitoring With Profile Radiography

Plant Condition Management Strategies

Effective MOC — The Vital Link in Process Piping Integrity

Remaining Life Predictions for Reformer Catalyst Tubes

Results of Degassing of Refinery Steel Components Prior to Welding

Turnaround Planning Using Reliability, Availability and Maintainability (RAM) Analysis

1997 Inspectioneering Journal Article Index

The ASME PCC continues to meet four times per year during ASME Code Week. The last meeting was on December 9, 1996. Over 50 members and visitors were in attendance. At that meeting, both subcommittees (Flaw Evaluation S/C and Inspection Planning...

Download Pinnacle's Economics of Reliability Report - Refining to see how reliability is affecting profitability.

Damage of carbon steel pressure vessels due to various in-service damage mechanisms continues to be a serious concern in the refining and petrochemical industries. A survey conducted in 1990 by the NACE T-8-16 Work Group to determine the nature and...

In the Jan/Feb issue of the IJ, I mentioned how important the Management of Change (MOC) process is when it comes to maintaining safe, leak-free piping systems; stating that we in the inspection business cannot do it alone; that is, we taint the...

Shortly after World War II, the FRP industry expanded rapidly into many areas. Chemical tanks were first fabricated in the 1950s. A comprehensive standard was needed and in 1969 a consensus standard was issued by the National Bureau of Standards:...

At recent meetings with refinery groups, a tool that is typically used during the design and construction of refinery units was presented. Then, brainstorming took place on ways this tool could be used in the refineries for day-to-day operation,...

Engineering, Procurement and Construction (EP&C) companies have a monumental task to maintain accurate NDE records on major new construction projects. Fluor Daniel has developed and put in use over the last several years a database program for...

Continuing with the theme "a billiard ball on the end of a fly rod," this month we will look at one alternative to mounting a heavy block valve on a small diameter nipple in vibrating conditions. A popular situation is where the purpose of the...

In a past issue, we discussed one solution to the instrument line block valve pendulum problem. This was where the valve assembly can be mounted remotely from the vibrating product line, such as at-grade. This issue covers two possibilities where...

Lessen downtime by enhancing your plant infrastructure, ensuring mechanical integrity, and extending equipment lifespan. Contact us for on-demand engineering expertise in assessment, problem-solving, specialized testing, and preventative solutions.

There are a number of terms to describe commonly experienced problem conditions with reciprocating compressors. One of the terms that I have always appreciated is the pendulum action of a large unsupported mass on the end of a vibrating pipe.

This is the second in a series of articles on piping inspection. In the last article, I enumerated four inspection issues that I believe contribute to inadequate piping mechanical integrity in the hydrocarbon process industry.

It's probably more important to those of us who don't have a brain tumor. Unfortunately, it's precisely because piping inspection is not neurosurgery that it's often done poorly, which can lead to significant impacts on process unit reliability, or...

This is the fourth in a series of articles on piping inspection that I'm writing for the Journal. One of the previous ones dealt with improving thickness data taking accuracy with digital ultrasonic methods. This article is a "sister article" that...

Regulatory requirements such as OSHA 1910, industry codes and practices coupled with an international drive for more cost-effective preventative maintenance are leading the industry toward data information management systems to assist in organizing...

This task though tedious and exasperating is a key part of the operation. Plant personnel often find ingenious uses and filing systems for key data such as UW 1 forms. The more remote the plant site is, the more extraordinary the hiding places. In...

The API Commitment on Refinery Equipment (CRE) has chartered a task group to develop an API recommended practice (RP 580), which will detail all the vital aspects of Risk-Based Inspection. This standard will not detail or propose any one specific...

This is Part II of a series of reliability of coke drums. Part I discussed some of the causes of bulging and cracking in coke drums. Here, the effect of operation on damage will be covered, along with possible solutions for increasing drum life...

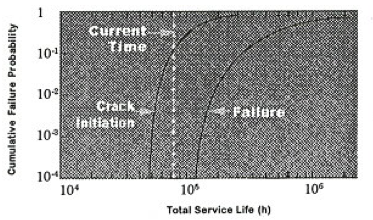

Reformer catalyst tubes are commonly manufactured from high strength, creep and corrosion resistant alloys. They are relatively thick walled and are usually produced by centrifugal casting. Their lives are limited by creep, driven by a combination...

Case 1: Fuel Gas to Boilers in boiler house: in 1992 two flanges were installed for installation of knock blinds. No degassing was completed. Both welds were radiographed and noted as acceptable. Case 2: Alky Unit Flare Header: No degassing...

The amount of serious questions regarding the various technology options for implementing an effective RBI program is growing by leaps and bounds. I, for one, have seen many forms of what various organizations refer to as RBI. Remember that there...

AWS, in conjunction with the Edison Welding Institute and The Welding Institute, are offering a program for the certification of NDE operators. The certification follows the operators. Areas for certification are PT (penetrant testing), MT...

Radiographic film provides an inexpensive method of ensuring the quality and structural integrity of construction over time. Much of today's analysis being performed with Non Destructive Test (NDT) radiographic film is done visually using light...

A paper entitled, "Turnaround Scope Development Through Reliability, Availability and Maintainability Analysis," prepared by Shailendra K. Gupta and John E. Paisie, both senior reliability engineers with Sun Oil Company, Toledo, OH, USA, was...

This is an update on NDE research and development activities previously reported on in the Inspectioneering Journal. Companies wishing to join/contribute to these groups' activities, provide input and direction, and reap the benefits should contact...

Our business paradigm is going through tremendous changes, as most of our readers can attest to. Look at the mega-mergers looming and happening in the petroleum business along with the tight margins most of them operate on.