Collecting Quality Failure Rate Data for the Chemical Process Industry

Food for Thought - Risk Based Inspection (RBI)

Measuring the Effectiveness of the Pressure Equipment Integrity Management Process

Remote Visual Testing (RVT) For Internal Pressure Vessel Inspection

Risk Based Inspection and Regulatory Compliance - They Can Co-Exist

Can TOFD Replace Conventional UT for Weld Inspection?

Post-weld Inspection Using Laser Vision

Reducing Plant Asset Losses and Environmental Incidents (Part 1)

EMATS: A Technology Whose Time Has Come?

Inadequate Inspection Documentation Cited in One of Four Root Causes In 1995 Explosion

Incorporation of Risk-Based Inspection into API Standards 510, 570 and 653

1998 Inspectioneering Journal Article Index

Inspection record systems, used to be just that, a place to "record" data. Our industry has spent many millions of dollars collection data to put into our "record" systems. The problem was trying to manage and utilize the millions of pieces of...

In Part 1 of my article, I focused on several issues that are vital to the successful application of any inspection information management system. In Part 2 of my article, I will concentrate on several...

TODF (time-of-flight-diffraction) is proposed as an option to Pulse-echo methods by some practitioners. It suffers from shortcomings that can limit its effectiveness.

The debate about advantages and drawbacks of the application of the TOFD (time of flight diffraction) approach for ultrasonic weld inspection should not forget the original reasons for its introduction in the 1960s. The major advantage at that time...

Quality failure rate data have long been needed by the Chemical Process Industry. Unfortunately, the emphasis too often has been on the collection of data rather than on its uses . One must answer the question of what to do with the data once it has...

During the past year, WIS has presented a number of papers about EMATs. The type of discussions that have followed the presentations has surprised us. The overall view of industry to EMATs has been: "Aren't EMATs still just a good lab tool? There...

Whether you decide for a Computed Radiography scanner with flexible imaging plates or a flat panel detector with the fastest imaging, or even combine the advantages of both technologies, DÜRR NDT's innovative systems offer high reliability and...

I have observed through literally hundreds of discussions and reading numerous articles on risk-based approaches that at least one potential business pitfall is appearing when owner-operators choose to begin with a "Level 1" (very qualitative)...

The use of Infrared Thermal Imagers, particularly for temperature measurement within an operating furnace environment, is reliant on the accurate evaluation of specific parameters, which the pyrometer requires in order to produce true temperature...

The Environmental Protection Agency (EPA) issued the report on this catastrophic failure that involved two storage tanks in a Pennsylvania refinery. The report issued March 20, 1998, stated that while both tanks had roof replacements since their...

The API Subcommittees on Inspection and Pressure Vessels & Tanks are ever vigilant in keeping up with current trends and state-of-the-art technology for in-service inspection of pressure vessels, process piping, and aboveground storage tanks. One...

In this first part of a two-part article, I will outline a process that our company uses to review and measure the effectiveness of our pressure equipment integrity management process. Then in Part 2, next issue, I will "fill in the blanks" on some...

In Part 1 of this article, in the last edition of the IJ, I introduced the work process that we use to assess the effectiveness of our pressure equipment integrity (PEI) management. It involves a self-assessment workbook filled out by site...

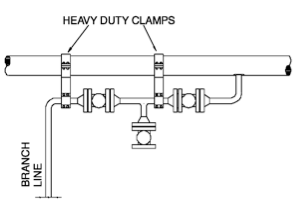

In a past issue, we discussed one solution to the instrument line block valve pendulum problem. This was where the valve assembly can be mounted remotely from the vibrating product line, such as at-grade. This issue covers two possibilities where...

Visual inspection is the most common nondestructive testing method. For critical applications, machine vision technology provides advantages over visual inspection.

Regulatory, civic and competitive pressures require we change to a proactive, rather than a reactive culture or environment with a supportive infrastructure. The concurrent evolution of cultural and infrastructural change relies upon effective...

Furnace tubes in the petrochemical and refining industries lengths' can exceed 2,000 ft., often with multiple serpentine bends. This can make them extremely difficult to inspect using conventional NDE methods. The following inspection tool (FTIS)...

Part 1 included a review of current tube inspection practices in convection and radiant sections of heaters/furnaces in the refining and chemical industries. The authors also presented a new inspection device combining laser image mapping of the...

Faced with stricter OSHA regulations and increased competitiveness in the global market, process facilities have looked toward a technical solution, including man-less entry into vessels, pressure vessels, and tanks for their internal inspections.

There is a potential for misconceptions about terms used regarding risk by non-risk management professionals. Understand that some risk is unavoidable. We can attempt to minimize risk to any extent desired, but without an effective process that...

Inspection to determine mechanical integrity is important to verify that equipment is suitable for intended use, i.e. to prevent or minimize the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals as required...

New inspection technology, when added to the proven practice of using tell tale holes (TTHs), proves effective in reducing significant releases and or catastrophic events that are related to internal corrosion / erosion of process piping. In fact,...

We have been asked many times by existing and prospective users of PCMS (a computerized, inspection database management system), how many TMLs (Thickness Management Locations) should be installed per piping circuit. These inquiries must be addressed...