| Date | July/August 2016 |

| Volume | 22 |

| Issue | 4 |

| Return to Journal Index | |

July/August 2016 Inspectioneering Journal Article Index

Many plants inspect PRDs on preset intervals as recommended by inspection code API 510, and implement inspection practices such as API RP 576. Just seeking PRD compliance with codes and standards usually results in mediocre mechanical integrity and...

This article details the basis for the lack of understanding about the potential for ultrasonic couplant auto-ignition and outlines an ALARP operating practice for mitigation.

This article will examine what can occur during the course of a Front Line Supervisor’s day that may hinder the execution of their expected duties, and what can be put in place to overcome those obstacles.

Companies have developed detailed programs for managing wide range of assets. However, unsustainability negatively impacts effectiveness of these programs. Reach out to us on how we can address sustainability through digital transformation.

The structural integrity of components is controlled by material properties, the presence of flaws, and levels of applied stress. Several factors such as temperature, type of loading, toughness, corrosion resistance, micro-structural stability, cost...

The instrumentation available to detect inadvertent material substitutions through positive material identification (PMI) has never been more available, portable or powerful than it is today. For one industrial services company, Tacten Industrial,...

Joint integrity management remains at the top of many operators’ priority list. The discipline considers risk and drives safety to ensure we learn necessary lessons from past catastrophic failures, such as the Piper Alpha explosion in 1988,...

An overview of process piping vibration and evaluating piping systems in vibration service to reduce harmful vibrations.

Turnarounds operate at a different pace than routine work. Most plant-based inspection departments have historically struggled with Turnaround document control, such as integrating contractor reports into their routine data management system. Our...

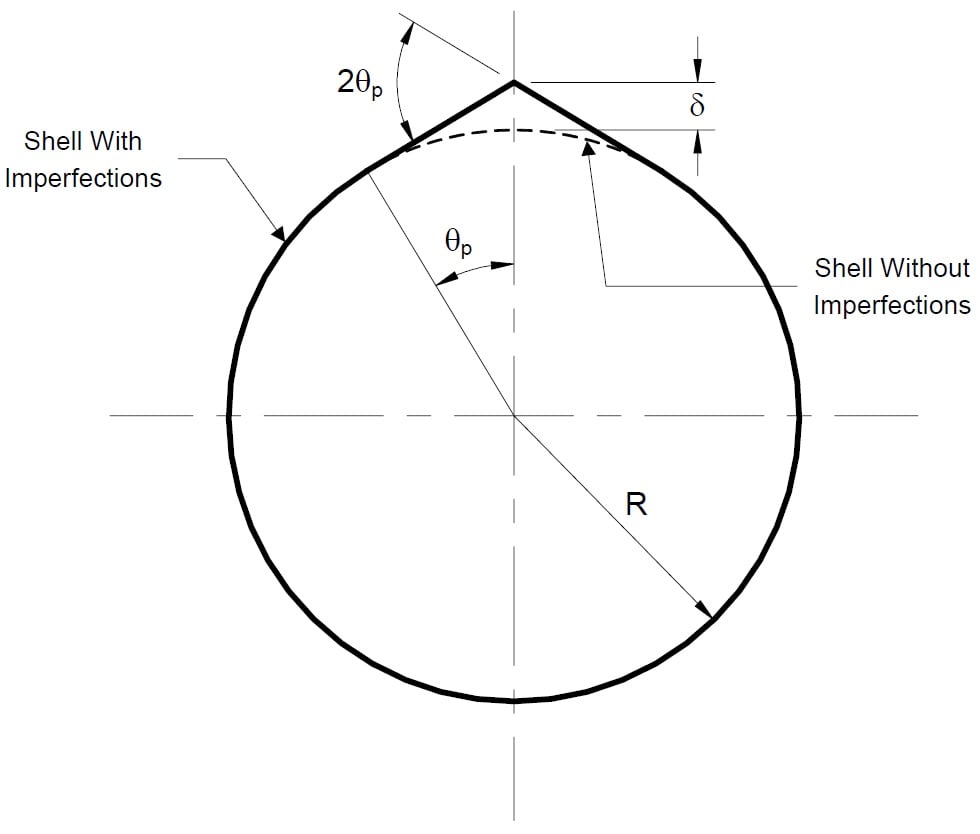

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.

An explanation of refractory including its uses and recent advancements in abrasion-resistant materials, dry-out/cure times, improved installation methods, and anchoring systems.