| Date | January/February 2016 |

| Volume | 22 |

| Issue | 1 |

| Return to Journal Index | |

January/February 2016 Inspectioneering Journal Article Index

The enormous decline in oil prices over the past 14 months has definitely slowed projects and changed the energy and production landscape. Despite this, refineries, petrochemical plants, and chemical facilities must continue to run safely,...

Traditional pressure vessel inspections often require taking assets out of service. However, MISTRAS’ Non-Intrusive Inspection (NII) programs provide data as good or better than internal inspections, while assets remain in service. NII is...

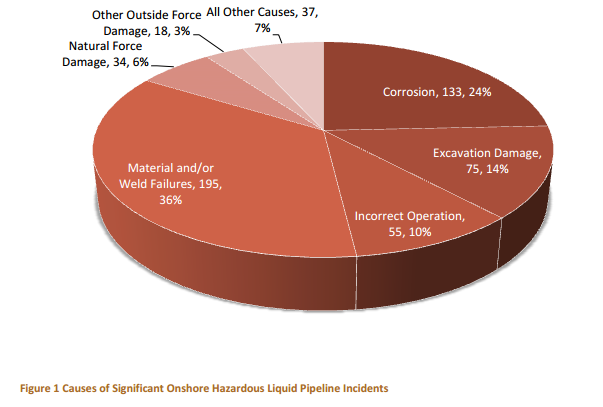

Pipeline management remains fraught with safety risks for operators and the environment. Last year, the Ontario Energy Board determined that a $12 billion oil pipeline proposed by TransCanada Corp. would pose more risks than rewards for the province.

It is a generally accepted fact that most Front Line Supervisors (FLS) come up “from the ranks” of the hourly staff. However, most companies provide neither training nor any type of preparation or guidance for the person they have now placed...

Heat exchangers operating in refineries or petrochemical plants must be thoroughly cleaned and inspected throughout their operational lifetime to ensure safe and efficient operations.

When heading down the path of becoming an inspection professional, it’s helpful to understand the characteristics that truly make someone an outstanding inspector.

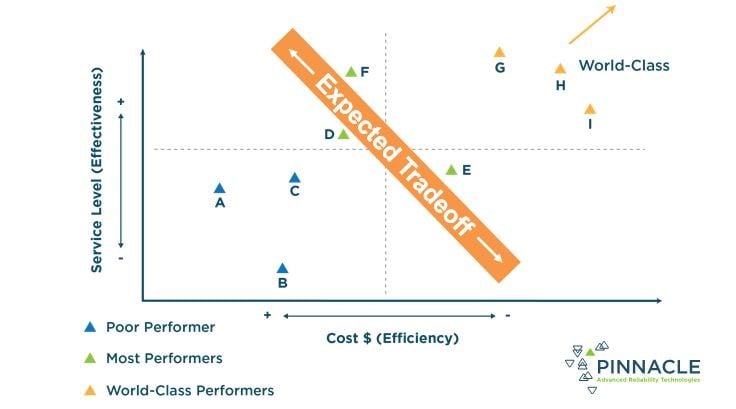

Equipment integrity and reliability programs are essential for refinery and chemical facility operators. The processes of the programs are developed to ensure safety, optimize component life cycles, and promote smooth and economical operations.

In Part 1 of this 2-part series, published in the July/August 2015 issue of Inspectioneering Journal, I discussed corrosion control methods and some effective techniques for inspecting ASTs, and also identified several root causes of AST failures in...

You probably already know that inspection apps for tablets and smart phones exist, and have notions of how these technologies can improve efficiencies in the field and beyond.

Fixed equipment in a refinery can be susceptible to corrosion from the process side, necessitating an inspection strategy to understand the condition of that equipment. Online measurement of pipe and pressure vessel wall thickness is made possible...