Importance of Data Management and Availability to Produce an Effective Inspection Program

Information- Gathering Session on SP0169 (formerly RP0169)

North Sea Accident - Workers in an Enclosed Space

Risk Based Inspection - The Regulatory Acceptance Process

Update on the New API/ASME In-Service Inspection Joint Code Committee (ISIJC)

Detection of Small Leaks in Liquid Pipelines: Gap Study Analysis of Available Methods

Don't Overlook the Value: Questions and Answers from the Inspectioneering Discussion Forum

In Memory of John Dunlop McMillan: 1945 - 2007

New Joint Standard API 579-1/ASME FFS-1 Now Available

What's new with API/ASME In-Service Inspection Standard

Assessment of Pipe Wall Thickness Radiation Technique

The New Age of Pipeline Inspection - Long Range Ultrasonic Testing (LRUT) Update

Inspection of Heat Exchanger, Condenser & Fin Fan Coolers Tubes - An Update

Risk-Based Inspection: Utilizing Metrics, Maximizing the Value

2007 Inspectioneering Journal Article Index

In previous parts of this series, I have covered many corrosion and degradation issues, some environmental cracking diseases, metallurgical degradation mechanisms, issues associated with welding and some external corrosion problems. In part 14,...

When we talk about welding QA/QC we typically focus on the technical requirements and what QA/QC is needed to assure that the technical requirements are met. Examples include the preheat, interpass, and PWHT temperatures and how to assure that the...

In the welded condition many stainless steels are susceptible to rapid intergranular corrosion or stress corrosion cracking. This is because the heat from welding sensitizes the base metal heat affected zone (HAZ) and the weld.

A myriad of issues need to be considered before welding to or repairing weld overlayed or clad equipment. (By clad we mean roll-bonded or explosion bonded, i.e. basically 100% metallurgically bonded, and not a loose or seam-welded liner, e.g., not...

The American Petroleum Institute (API) is issuing this publication's announcement to inform companies involved in the distribution, transportation, storage, and blending of denatured fuel ethanol of a potential for metal cracking and product leakage...

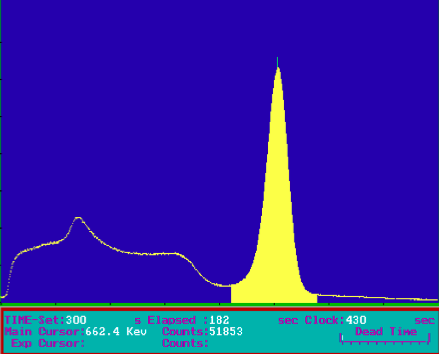

Degradation of materials with time during service is a common phenomenon for all engineering components. Hence periodic inspection is required to ensure structural integrity and availability for service. During in-service inspection (ISI), wall...

Sunray,Texas, March 9, 2007 - The U.S. Chemical Safety Board today announced it is conducting a full investigation of the propane fire that occurred February 16 at the Valero McKee Refinery here, seriously burning three workers and forcing the...

Interested in a review of liquid pipeline leak detection technology focused on monitoring and detection of small leaks?

The Inspectioneering Journal Discussion Forum is a great storehouse of knowledge and experience for people involved in fixed equipment reliability. A few samples of discussions follow, to motivate you to participate.

Facilities are often content in compiling event data, entering thickness measurements, assigning a system description, tracking work requests and recommendations in their databases. These are certainly valuable data points but using your database...

Learn how you can safeguard integrity, reliability, instrumentation safety, and more.

As many of us in the equipment reliability business know, John was extremely active in developing and implementing advanced ultrasonic technologies. He was an innovative leader in our industry and had an impressive list of patents.

Because of widespread interest in the proposed revision in progress to NACE International standard SP0169 (formerly RP0169), "Control of External Corrosion on Underground or Submerged Metallic Piping Systems," NACE is sponsoring an...

Tube Inspection is a vital tool for the refining and petrochemical industries. Heat exchangers and condensers are designed to sustain 100% separation between the products in the tube (tube side) and the products in the vessel (shell side). A...

Since the publication of NACE MR0175/ISO 15156, "Petroleum and natural gas industries- Materials for use in H2S-containing environments in oil and gas production," in December 2003, the ISO Maintenance Panel set up to maintain this widely used...

NACE International has approved two highly anticipated standards dedicated to the control of internal pipeline corrosion.

The assessment procedures in this Standard can be used for Fitness-For-Service assessments and/or re-rating of equipment designed and constructed to recognized codes and standards, including international and internal corporate standards.

The Inspectioneering Journal was unable to validate this report but it still serves well for all of us who enter equipment as an example not to take lightly, safety procedures that should not be ignored, side stepped nor steps skipped. Here is the...

Over the past 18 years of serious RBI involvement, it has become clear to me that there are certain hurdles, that when "cleared", have paved the way to jurisdictional acceptance of RBI (and fitness for service, for that matter). This article will...

An earlier version of this updated article appeared in the January-February 1998 issue of the Inspectioneering Journal. It is hard to believe that nine years have passed so quickly. Fortunately the industry, as a whole, has learned much and...

Antea delivers highly flexible risk-based asset integrity software with 3D Digital Twin integration to optimize maintenance, reduce risk, and improve mechanical integrity for oil and gas, power generation, and chemical plants and facilities....

This is part 2 in a multi-part series. Part 1 set the stage in explaining the basics of RBI. As I am most familiar with API Base Resource Document 581, I will continue to use this technical basis for this article.

The integrity of pipelines is a natural concern for pipeline operators, and so the ability to detect corrosion, erosion and mechanical damage in pipes is therefore of significant interest. Traditional methods of detection, such as pigging and...

On July 20, 2003, a release of chlorine gas from the Honeywell International, Inc. (Honeywell) chemical plant in Baton Rouge, Louisiana, resulted in injuries to seven plant workers and issuance of a shelter-in place advisory for residents within a...

Washington, DC, March 22, 2007 - Carolyn W. Merritt, Chairman of the U.S. Chemical Safety Board (CSB), told a congressional committee today there should be increased oversight of the oil refining industry by the Occupational Safety and Health...

The ASME/API Inservice Inspection Joint Committee is continuing with its charter to develop and maintain a standard addressing inspection, repair, alteration and rerating for pressure vessels and piping systems after they have been placed into...

In May of this year, a workshop was presented at the annual NPRA Reliability and Maintenance Conference at the George R. Brown CC in Houston. This article is a reader’s digest summary of what was presented at that workshop by the four...

In my travels around the world as one of the primary API RBI 580/581 training course instructors the question always comes up, “What risk threshold or tolerable risk should I be using?” and “If I do not have one, how can I implement RBI?”

From time to time, I'm asked why some operating sites don't seem to pay adequate attention to the need to protect and preserve pressure equipment integrity (PEI). Too often a few sites don't seem to "get it" until they have a major process safety...