A Roadmap for Successful Turnaround Inspections: Turnaround Completion and Inspection Documentation

Dual Mode Pulse Reflectometry – A New Approach to Heat Exchanger Tube Inspection

Effective Integrity Management Programs for Steam Reformers

Key Performance Indicators – Understanding is Key

Sands of Time Create The Mechanical Integrity Compliance Officer (MICO)

Save Time and Cost for Turnarounds Using Phased Array Technology

The Role of Process Unit Corrosion Reviews on Inspection Planning, RBI and IOWs

The Top 10 Reasons for FEMI Failures in the Hydrocarbon Process Industries

Achieving a Comprehensive Fired Heater Health Monitoring Program

Leveraging RFID Technologies for Pipeline Asset Management

Stress Assisted Corrosion and Fitness for Service in 66 Year Old Boilers

The Current State of Pipeline Integrity Management

The Top 10 Reasons for FEMI Failures in the Hydrocarbon Process Industries

A Roadmap for Successful Turnaround Inspections: Turnaround Inspection Execution

ABSA’s Unique Approach to Pressure Vessel Safety Administration

Avoiding 5 Common Pitfalls of Pressure Vessel Thickness Monitoring

Corrosion Under Insulation and Best-Fit Solutions

ISO 55000 – What You Need to Know

Optimize FPSO Operations through Certification and Risk Management

The Changing Role of the Unit Inspector

Assessing the Reduction in Spill Risk of the Keystone XL Special Conditions

Criticality Assessment of Piping Systems for Oil & Gas Facilities

Fitness for Service from an RBI Point of View

Heater Tube Inspection and Remaining Life Evaluation

How Facilities Can Better Ensure SPCC Compliance

Navigating ASME Section VIII (Div.1): Managing Your Pressure Vessels

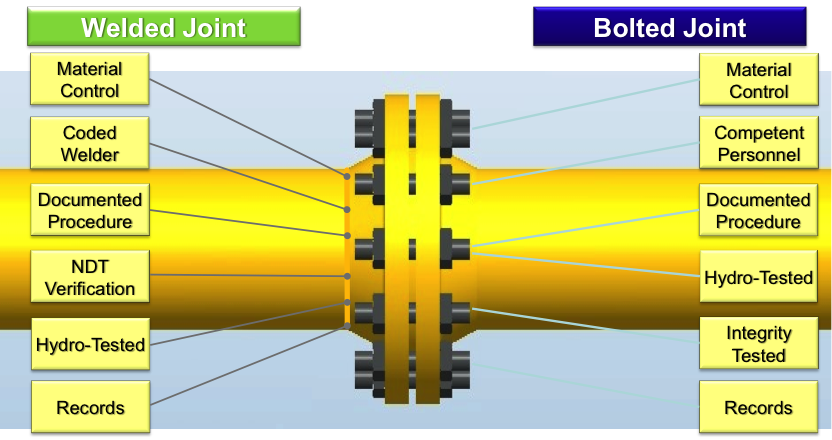

The Pathway to ASME PCC-1 2013 Appendix A Compliance and its Critical Importance

The Three Tiers of Most Fixed Equipment Mechanical Integrity (FEMI) Programs

12 Key Ingredients of a Successful FFS Team

A Discussion on Strategies for Effectively Transferring Knowledge to the Next Generation

A Roadmap for Successful Turnaround Inspections: Pre-turnaround Inspection Planning

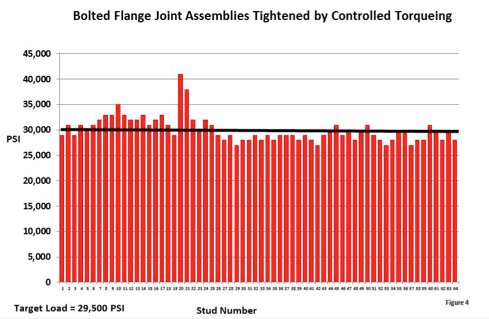

Best Practices of a Joint Integrity Program

Clay White Takes the Reins as Chair of API

Is Your Killed Carbon Steel Resistant to High Temperature Sulfidation?

Managing Asset Transfers: Negotiating the Deal and Minimizing Risk

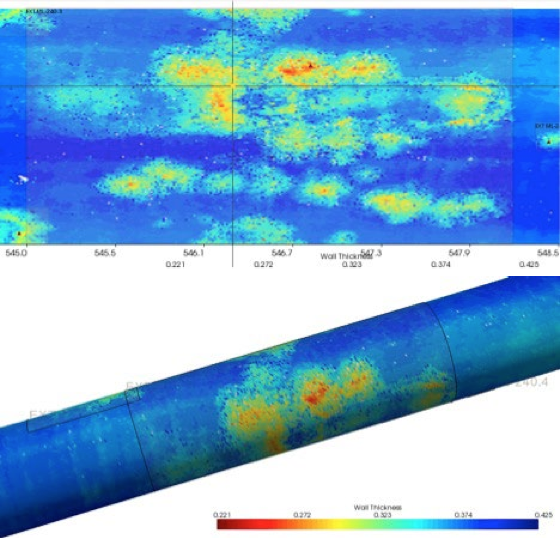

New Inline Inspection Technology Helps Ensure Terminal & Pipeline Integrity Management Success

A Discussion on Hydrogen Bake-Outs

Avoiding HTHA Failures: An Owner-User Perspective of the HTHA Risk Mitigation Process

Corrosion Testing with Real-Time 2-D Ultrasound Camera Imaging

Drones for Visual Testing & Inspection

Managing Asset Transfers: Negotiating the Deal and Minimizing Risk

Managing Fired Furnace Tubes in Refineries

Navigating ASME Section VIII (Div.1): Managing Your Pressure Vessels

New Standards for Quality Control and Assurance of Bolted Flanges

2014 Inspectioneering Journal Article Index

Since important decisions will be based on the results of the fitness-for-service (FFS) determination, you need to be sure that you have a strong FFS team. But what are the key ingredients of a good FFS team? This article provides some guidelines to...

This is the second of two articles published in Inspectioneering Journal discussing the value of hydrogen bake-outs. Our first article was published in the May/June 2013 issue and received a great response from the Inspectioneering community. In...

Recently, Inspectioneering Journal sat down with Stress Engineering’s Bobby Wright and Ralph King to discuss how companies can better transfer and preserve industry knowledge.

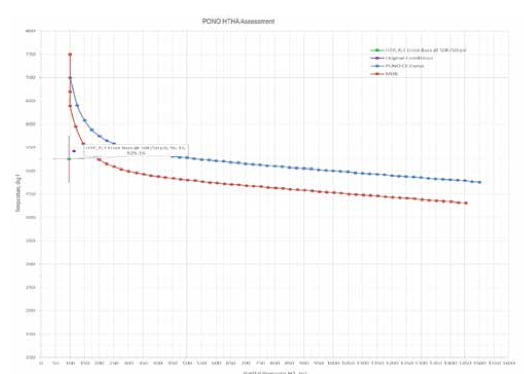

This article provides background on HTHA, discusses some current developments in HTHA inspection and mitigation, and describes how one refiner is instituting an HTHA risk management plan for its refineries along with challenges they have encountered.

In this issue of Inspectioneering Journal, I detail a roadmap for inspection activities during turnaround executions. This roadmap includes the critical elements of turnaround inspections, the keys to optimizing inspection activities, and the...

Periodically, oil refinery and petrochemical plant operating companies conduct complex turnarounds for a variety of reasons, including but not limited to, scheduled maintenance, facility upgrades, and code compliance. In this series of articles...

One of the major challenges inspectors and plant operators face after each turnaround is to ensure that all repair and scope work is and was completed in accordance with the client’s requirements. Sometimes that verification will be to ensure work...

A small leak from top tubesheet-to-tube welds prompted further inspection of the 1¼Cr- ½Mo Ammonia Converter Boiler Feed Water (BFW) Exchanger during a planned shutdown. Further cracks were identified in the top channel to tubesheet butt weld that...

The Province of Alberta has a long history of pressure equipment safety dating back to 1897 when the first boiler laws were introduced to regulate the new technology of steam boilers. Boiler inspectors were hired, and soon thereafter the Alberta...

In today's chemical and refining industries, sustained long term reliability of facilities is critical to profitability and competitiveness. In fact, history shows that differences in operating expenses between best-in-class refineries, and poor...

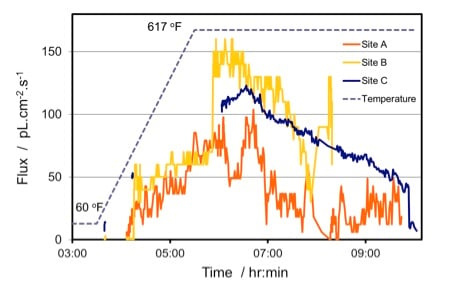

For the past 30 years, infrared (IR) thermometry has been used to monitor tube metal temperatures in refining and chemical furnaces. Tracking temperature levels and variations determine performance capability limits and reliable tube life. However,...

Our proprietary furnace tube inspection system, FTIS is an ultrasonic inspection technology capable of rapid, automated fired heater coil inspection in refinery fired heaters. The data captured by our furnace tube inspection system is...

The rules and regulations applying to U.S states, cities and Canadian provinces and territories concerning piping, pressure vessel and storage tank inspection can be described as "a coat of many colors," and are meant to represent continuous...

An adequate characterization of the Keystone XL special conditions from the perspective of pipeline integrity and risk would be advantageous from the system onset for identifying latent flaws in the system spill prevention plans.

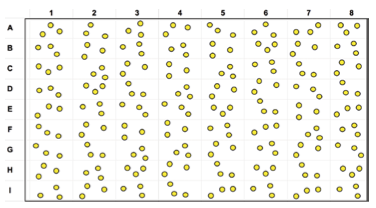

One of the more common inspection monitoring programs for pressure vessels is to perform thickness measurement at Corrosion Monitoring Locations (CMLs) to allow monitoring of minimum thicknesses and provide estimates for corrosion rates. These...

The intent of these two articles is to share lessons learned from recent experiences setting up a comprehensive HTHA review process across multiple refineries, and to help other operators define and mitigate the HTHA risk to an acceptable level.

Joint integrity programs (JIP) should be an integral part of every refinery, petrochemical, production, or other industrial-complex facility operations.

Inspectioneering is pleased to announce that our friend, colleague, author and industry leader, Clay White, has recently taken over as chair of API’s Subcommittee on Inspection (SCI).

Technicians inspecting oil & gas installations and petrochemical plants employ a wide variety of nondestructive testing (NDT) techniques. A new technology has recently been developed that utilizes a real-time portable imaging device which has...

As any refining or petrochemical plant manager knows, corrosion can occur on insulated piping at any facility. CUI has been a major challenge for the petrochemical and refining industries since the first pipelines were insulated with wrappings.

Ensuring the integrity of process piping systems in the Oil & Gas industry (specifically those related to the ASME Code B31.3) is a key issue with respect to the process, business, safety, and the environment. However, in the current cost reduction...

UAS (Unmanned Arial System) drone technology has numerous applications, including anything at elevated heights or where human access and/or occupancy are prohibited, or in the case of confined spaces, limited.

Oceaneering's splash zone inspection services will help you confidently detect flaws and accurately extend asset life with our comprehensive inspection and fitness-for-service maintenance plans.

Dual mode pulse reflectometry shows promising results in detecting a wide range of defect types and sizes in heat exchanger mock-ups.

Steam reformers are critical assets for the successful operation of hydrogen, ammonia, and methanol plants. The steam reformer is also one of the most expensive assets in these facilities. Catalyst tubes inside the reformer are one of the most...

As an RBI consultant, I frequently get involved in discussions spawned from a misunderstanding of the relation between Risk Based Inspection (RBI) approaches and Fitness for Service (FFS) assessments. Questions like: If thickness is below the...

The following interview with Rich Roberts provides answers to some of the questions our readers have about small, specially designed pigs carrying NDE technologies that can inspect nearly every area of a tube from the coils interior surface.

Several catastrophic spills over the past few years have sparked significant interest in oil spill prevention across the industry. Not only do facilities with large amounts of oil want to prevent environmental damage, loss of product, and civil...

High temperature sulfidation is probably the most well- known corrosion mechanism in the oil refining industry because it occurs in large sections of the refinery.

One of the more popular topics discussed and debated vigorously in the asset management community is the potential impact of the ISO 55000 series of standards, which was just released in January of 2014 and is the first set of international...

Key Performance Indicators or KPIs are important for businesses to track measurable progress, or a lack thereof, as compared to pre-defined goals or benchmarks. For those of us in the inspection, fixed equipment reliability world, the same holds...

Recently developed RFID best practices provide an opportunity for pipeline businesses to transform their asset management and pipeline integrity management processes away from traditional paper-based systems to more efficient, highly-integrated...

This follow-up article compliments the one published in the last issue by focusing on the techniques routinely employed by Buyers in the purchase of complex oil and gas assets, paying special attention to three sections found in most asset purchase...

Inspectioneering Journal is focused on informing its readers of innovative and trailblazing trends in day-to-day asset integrity management and asset risk reduction activities. How does an entity best manage risk, however, when purchasing or selling...

Fired furnaces in the petrochemical and refining industry are critical pieces of equipment that can have a major impact on process unit safety, reliability, and economics. They are complex pieces of equipment, where tubes and other pressure boundary...

Inspections, repairs, modifications, or Fitness-For-Service (FFS) assessments on an old, unfired ASME Section VIII (Div. 1) pressure vessel - Which ASME Section VIII (Div. 1) Code Edition should you use?

Inspections, repairs, modifications, or Fitness-For-Service (FFS) assessments on an old, unfired ASME Section VIII (Div. 1) pressure vessel - Which ASME Section VIII (Div. 1) Code Edition should you use?

New inline inspections and integrity management systems allow operators to understand the complexities and economics of terminals’ and station’s complex aging pipeline infrastructure.

If necessity is the mother of invention, then the American Society of Mechanical Engineers (ASME), the Occupational Safety and Health Administration (OSHA), and the Environmental Protection Agency (EPA) are the parents of guidelines, standards,...

More than 170 FPSOs currently operate worldwide with more expected to go into service over the next few years. The challenging environment in which these complex offshore energy assets operate requires safe and reliable systems that ensure continued...

The role of an API inspector is rapidly changing. Necessary skills for success have transformed as technology, standardization, and regulations have become part of the way of life.

The introduction of PAUT is a challenging effort initially, but can have a very positive impact on your first TAR and become a routine inspection for future TARs. When fully implemented, radiation safety boundaries can be reduced significantly or...

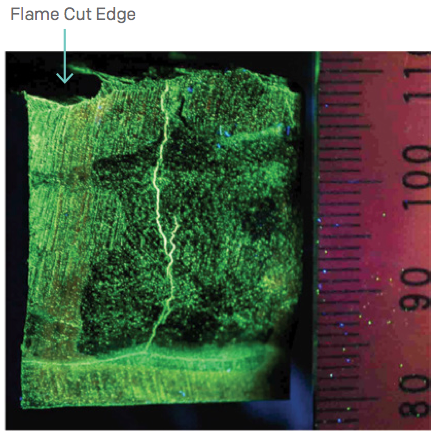

Maintaining mechanical integrity for aging power boilers can be challenging. This article provides a case study on how mitigating one damage mechanism led to the discovery of another, and how refinery engineers collaborated with industry experts to...

One difficulty new company inspectors typically have is becoming comfortable in their new role. This is due to the fact that they have received little guidance about where they fit in with the "team." Where are they on the organization chart?

The pigging industry has developed a tremendous range of techniques and technologies, and it is probably fair to say that there are few pipelines in the world that cannot be cleaned and inspected, although the success of such operations will often...

In November 2013, ASME released its updated PCC-1 guidelines for pressure boundary bolted flange joint assemblies. Contained within the document is Appendix A, which represents a major change from the previous 2010 release and is considered to be...

Today, more than ever, refinery operators are focused on maintaining safe operations for their employees and extending the life cycle of valuable operating equipment to optimize efficiencies and avoid expensive unforeseen shutdowns. When process...

Piper Alpha is an offshore oil and gas platform that suffered an explosion in July 1988, still regarded as the worst offshore oil disaster in the history of the United Kingdom. The 25th anniversary of the disaster was commemorated across the...

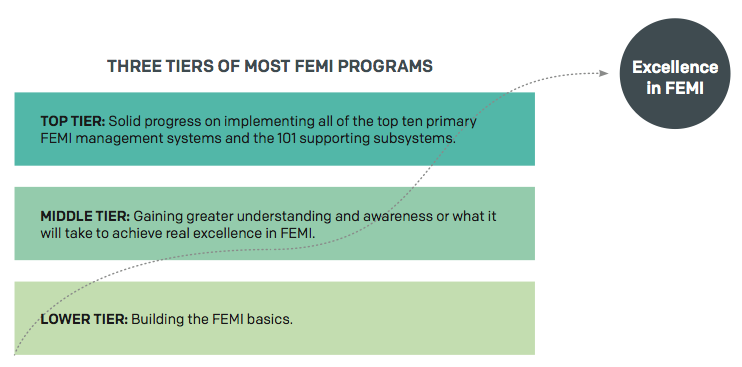

There are typically three tiers to pass through for most fixed equipment mechanical integrity (FEMI) programs before they reach excellence in FEMI. In my 45 years in the FEMI business, I have observed FEMI programs in all three tiers (phases).

Based on my 45+ years of experience working with fixed equipment mechanical integrity (FEMI) issues in the refining and petrochemical processing industry, this article summarizes what I believe are the top 10 reasons why pressure vessels and piping...

Based on my 45+ years of experience working with fixed equipment mechanical integrity (FEMI) issues in the refining and petrochemical processing industry, this article summarizes what I believe are the top 10 reasons why pressure vessels and piping...