Introduction

There is no substitute for safety, and the path toward putting safety protocols and mechanisms in place varies by industry and company. Whatever the type of business, new innovations in technology can help companies implement safety initiatives in a more cost-effective and efficient manner.

In numerous industries that require elemental and material testing, including the oil and gas, power generation, and petrochemical industries, positive material identification (PMI) is at the forefront of any operation. In fact, an increasing number of facilities are adopting a 100% PMI program to ensure that every metal component is made up of exactly the desired chemical composition. To do so, more and more plants are adopting portable x-ray fluorescence (XRF) technology, which brings increased reliability and accuracy to material analysis in a manner that can reduce the risk of accidents while offering significant cost and time savings.

Rapid Technological Developments

Over the last decade, analysis techniques that had previously only been feasible in a laboratory setting have become available to more quality control personnel in the field. Technology, in the form of handheld instrumentation, is now smaller and faster which has had a beneficial impact on refineries, power plants, chemical plants, and other types of facilities by making sure the right materials will be used and have been installed in the right places.

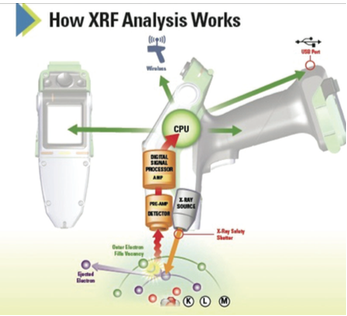

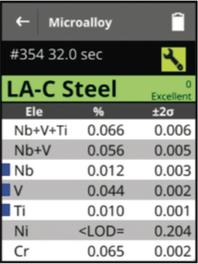

XRF spectroscopy, which bombards a sample with high energy x-rays, analyzes the composition of a sample by measuring the spectrum of fluorescent x-rays emitted by the different elements. While XRF spectroscopy has been used for about 60 years, the technology has recently become portable through the use of a miniaturized tube to emit x-rays. When a user simply points and shoots, a primary x-ray beam is sent into the sample via the x-ray tube, releasing energy in the form of fluoresced x-rays. These x-rays are measured by a silicon drift detector (SDD), which can identify and quantify the element or elements. Today, a handheld XRF spectrometer can instantaneously determine not only the concentration of each element in a sample, but also identify the alloy name, thanks to an on-board alloy library.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.