API 579-1/ASME FFS-1, Fitness-For-Service, is a standard developed and published jointly by the American Petroleum Institute (API) and ASME. It describes several fitness-for-service (FFS) assessment techniques that help ensure the safe and reliable operation of pressurized equipment used in oil & gas, petrochemical, and chemical facilities. This document was originally published in January of 2000, with the most recent 4th Edition being released in December of 2021.

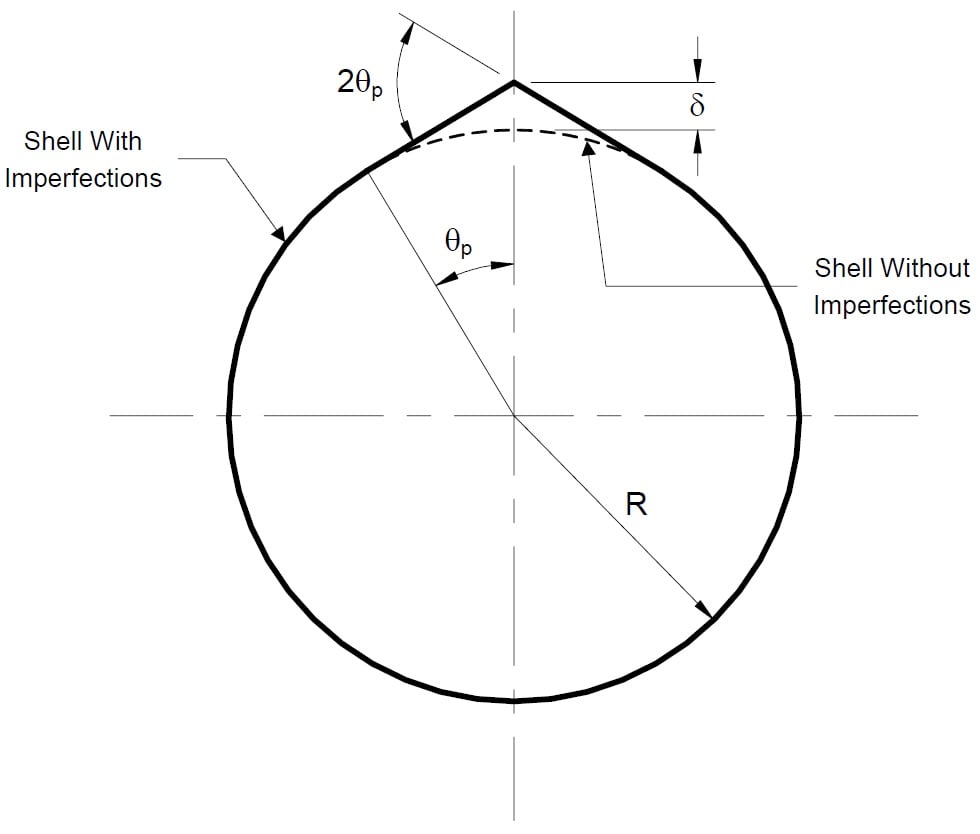

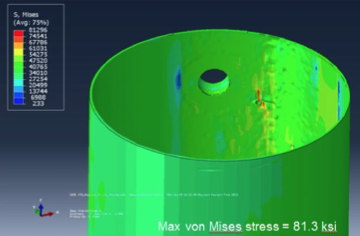

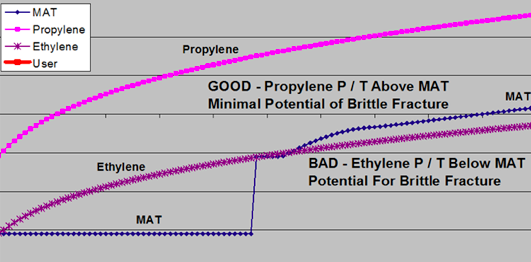

API 579-1/ASME FFS-1 provides procedures for performing proper fitness-for-service assessments and/or rerating of equipment that is designed and constructed to recognized codes and standards. This standard contains numerous sections on assessment procedures for calculating the impact of damage mechanisms such as brittle fracture, general metal loss and local metal loss, pitting corrosion, blisters and laminations, weld misalignment and shell distortion, crack-like flaws, creep damage, and fire damage.

This standard has procedures for evaluating several different types of equipment (pressure vessels, piping, and tanks) that may contain flaws or damage. These include the evaluation and rerating of pressure vessels designed based on the the ASME Boiler and Pressure Vessel Code, and piping systems that were constructed to either the ASME B31.3 Piping Code or those constructed under API 650 and 620, along with pressure containing equipment constructed to any other codes that are recognized in the publication.

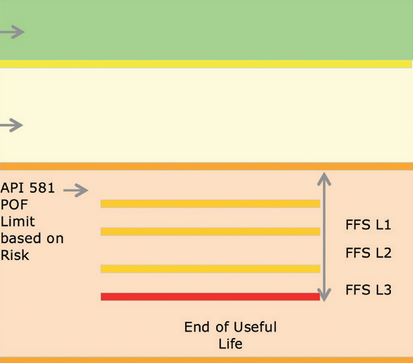

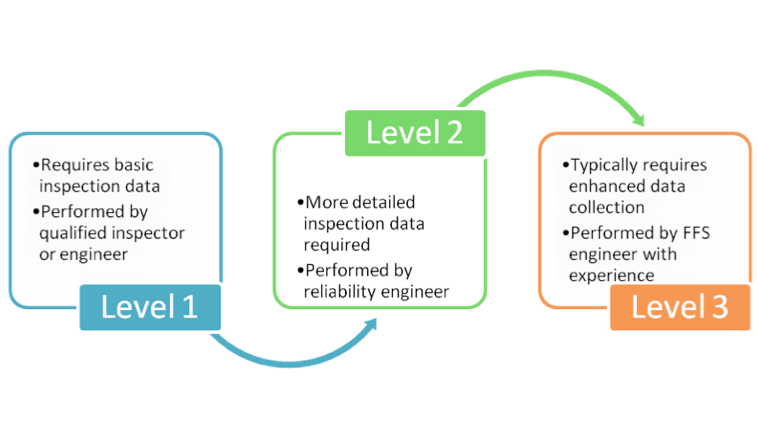

It covers both the present integrity of the component, given a current state of damage, and the projected remaining life. Qualitative and quantitative guidance for establishing remaining life and in-service margins for continued operation of equipment are provided in regards to future operating conditions and environmental compatibility. The procedures are not intended to provide a definitive guideline for every possible situation that may be encountered. However, flexibility is provided to the user in the form of an advanced assessment level to handle uncommon situations that may require a more detailed analysis.

API 579-1/ASME FFS-1 also has appendices on several other important topics, such as equations for determining MAWP, thickness, and stress in components, methods of stress analysis for Level 2 and Level 3 FFS assessments, a compendium of stress intensity solutions, guidance on material properties, failure modes and damage mechanisms, validation of assessment procedures, and information on submitting technical inquiries to API, among other things.

Related Topics

- API 560 - Fired Heaters for General Refinery Service

- API 594 - Check Valves: Flanged, Lug, Wafer, and Butt-Welding

- API 620 - Design and Construction of Large, Welded, Low-Pressure Storage Tanks

- API 650 - Welded Tanks for Oil Storage

- API 660 - Shell-and-Tube Heat Exchangers

- API 661 - Petroleum, Petrochemical, and Natural Gas Industries Air-Cooled Heat Exchangers

- API RP 1160 - Managing System Integrity for Hazardous Liquid Pipelines

- API RP 1173 - Pipeline Safety Management Systems

- API RP 1176 - Assessment and Management of Cracking in Pipelines

- API RP 1188 - Hazardous Liquid Pipeline Facilities Integrity Management

- API RP 538 - Industrial Fired Boilers for General Refinery and Petrochemical Service

- API RP 571 - Damage Mechanisms Affecting Fixed Equipment in the Refining Industry

- API RP 572 - Inspection of Pressure Vessels

- API RP 573 - Inspection of Fired Boilers and Heaters

- API RP 574 - Inspection Practices for Piping System Components

- API RP 575 - Inspection Practices for Atmospheric and Low Pressure Storage Tanks

- API RP 576 - Inspection of Pressure-Relieving Devices

- API RP 577 - Welding Processes, Inspection, and Metallurgy

- API RP 578 - Material Verification for New and Existing Alloy Piping

- API RP 580 - Risk Based Inspection (RBI)

- API RP 581 - Risk Based Inspection Technology

- API RP 583 - Corrosion Under Insulation and Fireproofing

- API RP 584 - Integrity Operating Windows

- API RP 585 - Pressure Equipment Integrity Incident Investigation

- API RP 651 - Cathodic Protection of Aboveground Petroleum Storage Tanks

- API RP 75 - Safety and Environmental Management System for Offshore Operations

- API RP 751 - Safe Operation of Hydrofluoric Acid Alkylation Units

- API RP 754 - Process Safety Performance Indicators for the Refining and Petrochemical Industries

- API RP 934 - Materials and Fabrication of Heavy Wall Pressure Vessels for High-Pressure Hydrogen Ser

- API RP 939-C - Guidelines for Avoiding Sulfidation (Sulfidic) Corrosion Failures in Oil Refineries

- API RP 941 - Steels for Hydrogen Service at Elevated Temperatures and Pressures

- API RP 970 - Corrosion Control Documents

- API RP 982 - Inspection and Assessment of Refractory Linings

- International Organization for Standardization (ISO)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition