Answers for Today. Insights for Tomorrow

Company Profile

E²G | The Equity Engineering Group, Inc. is a technology-driven company that helps you prevent future failures, increase efficiencies, reduce downtime, maximize reliability, and minimize damage.We are a consulting, training, and software firm that is focused on creating and delivering practical and innovative solutions to solve your asset challenges. We are united and focused on creating and delivering knowledge, excellence, and technology.

KNOWLEDGE IS...

- Analyzing and assessing aging equipment to deliver safer and more reliable facilities

- Offering the most comprehensive corporate standards and delivery platform available in the world

- Researching new technologies and processes to push the boundaries of asset lifecycle management

- Participating on API, ASME, and other committees to guide industry best practices and advancements

EXCELLENCE IS...

- Integrating our clients’ legacy documents into the Equity Engineering Practices

- Training the next generation of engineers with mentoring and guided knowledge sharing

- Educating and empowering our clients with industry-relevant training courses

- Working with a team of all-stars who are 100% dedicated to E²G and its future growth

TECHNOLOGY IS...

- Providing the most advanced fitness-for-service software for our clients and E²G’s consulting team

- Assessing corrosion behavior using a patented thickness analysis methodology

- Innovating new inspection techniques that use consequence of failure and vibration data

- Using Bayesian networks to develop inspection plans for equipment subject to corrosion and pitting

Corporate Headquarters

20600 Chagrin Boulevard

Suite 1200

Shaker Heights, Ohio 44122 United States

216.283.9519

Consulting Services

Engineering expertise includes: Fitness-For-Service, Materials and Corrosion, Pipeline Services, Pressure Relief and Process Design, Mechanical Integrity, Risk-Based Inspection, Structural Engineering, Rotating Equipment, Vibration, and Instrumentation and Electrical.

Equity Engineering Practices (EEPs)

Best Practices, maintained by us & customized by you! 850+ engineering standards, 300+ piping classes, 20+ years in development, and 50+ SMEs dedicated to maintaining & expanding the EEPs. 100% customer retention rate. Choose the solution that delivers everything. Choose the EEPs.

Software

E2G’s software helps you make informed decisions to keep your plants safe and operating efficiently. Our fully integrated software supports equipment lifecycle management by integrating the latest API and ASME codes and standards with the depth of E2G’s engineering experience

Training: Virtual, In-Person or Custom

E2G believes in continuous learning. As active participants in API/ASME committees, we stay on top of industry technology, standards, and advancements. We develop high-quality training courses to support your professional growth. All API-U and ETI courses qualify for API’s CPD requirements.

Risk-based Inspection (RBI)

E2G’s RBI team has supported RBI implementation programs at refining, petrochemical, & chemical facilities across North America. As a pioneer in RBI methodologies, our experts use a multi-disciplinary approach to deliver the most experienced engineering consultancy for your RBI implementation.

Fitness-for-Service (FFS)

E2G conducts Level 3 FFS assessments to help you increase operational reliability & extend equipment life with informed run, repair, or replace decisions. Our engineers pioneered the advancement of FFS technologies & were lead investigators on API 579-1/ASME FFS-1.

E²G | The Equity Engineering Group, Inc.'s Inspectioneering Content

Engineering practices collections for downstream industries contain many useful practices for similar equipment used in midstream operations.

An overview of the types of in-service metallurgical embrittlement and other conditions that can accelerate embrittlement and increase the risk of cracking.

The final installment of the series concludes by providing practical insight into common brittle fracture and ductile tearing mitigation strategies.

A tribute to our colleague and friend, Dr. Martin Prager, Executive Director of the Welding Research Council, who passed away peacefully on November 1, 2023.

Not all operators apply the system design philosophy as intended by the ASME Code. Part of this reason could be due to confusion about how it is to be applied.

Part 2 of this three-part series on brittle fracture focuses on methods for evaluating the risk in pressure equipment and the evolution of screening and assessment methods.

This article is Part 1 of a new three-part series on brittle fracture and focuses on the fundamental concepts and damage morphology associated with the unstable rupture of pressure equipment.

Introducing the concept of damage management locations, together with remaining life estimates from CML data, offers a complete view for inspection planning.

Part 3 of this series focuses on practical damage mitigation and life cycle management techniques to avoid failures and corrosion in refinery pressure equipment.

This installment of Damage Control outlines the FFS methods available to analysts for evaluating wall loss such as sulfidation or high-temperature H2/H2S corrosion in pressure equipment

Common pitfalls in gathering inspection data using a case study where additional data gathering resulted in a significant improvement in FFS results.

Comprehension of the sulfidation corrosion reaction and the behavior of different materials in H2-free and H2/H2S environments is imperative for oil refineries.

Processing renewable feeds presents a blend of damage mechanisms for which existing hydroprocessing equipment may not have been designed. No “one-size-fits-all” approach exists to evaluate all the specific degradation concerns for a renewables...

Can our industry learn a lesson from baseball's data-driven approach to move us into the next evolution of data analysis?

Part 3 of this series provides pragmatic strategies for mitigating high-temperature creep damage in typical pressure component alloys.

The wealth of knowledge that can be incorporated into internal standards makes them an ideal resource for internal training initiatives and allow organizations to maximize the return on their investment in the standards program.

Part 2 of this Damage Control series on high-temperature creep discusses engineering evaluation methods that can be used to predict the remaining creep life of components. Comparisons between the Larson-Miller Parameter and the MPC Omega are offered.

This short blog article explains why developing an internal best practices collection is preferred over other options, and provides recommendations on how to best develop, implement, and maintain an internal best practices collection.

A focus on typical damage morphology and inspection methods used to identify and characterize high-temperature creep including examples of creep damage and in-service failures to offer insight into this complex damage mechanism.

This final installment of a 3-part series on SCC mitigation will provide practical, actionable steps to improve long-term equipment reliability through design, fabrication/welding, heat treatment, maintenance/repair, and process operating practices.

The assessment procedures in API 579 may also be applied to pressure-containing equipment constructed to other recognized codes and standards. The author will examine the application of these procedures to aboveground storage tanks.

Part 2 of the three-part series on stress corrosion cracking (SCC) that examines common engineering and FFS methods that can be leveraged to understand and evaluate the propensity for an existing form of SCC to lead to loss of containment.

An informative discussion with David Osage, President and Principal Engineer at The Equity Engineering Group, regarding the recent update to API 579/FFS-1, Fitness-for-Service, and why it's important to our industry.

This article provides an overview of some of the more common forms of stress corrosion cracking (SCC) with a focus on effective inspection methods for detecting these forms of cracking.

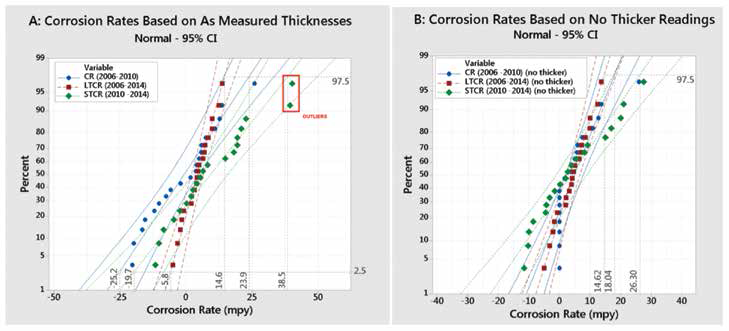

Applying advanced statistical analysis methods will provide owner/users with a RAGAGEP-accepted method for analyzing corrosion monitoring data while also integrating the latest improvements in inspection capabilities.

This edition of Damage Control will offer practical steps to mitigate different forms of wet H2S damage and help to minimize long-term inspection and maintenance costs related to wet H2S damage.

This issue of Damage Control offers a perspective on how to assess the different forms of wet H2S damage using modern FFS and computational analysis techniques with the safe operation of damaged pressure vessels, piping, and associated components.

This article summarizes the fundamentals of wet H2S-related damage mechanisms, offers some practical inspection guidance, and reviews a notable industry failure caused by different forms of wet H2S damage.

This article examines the quantitative tank RBI method found in API 581 and discusses uses for tank RBI other than deferral of scheduled internal inspections.

Practical steps to mitigate corrosion under insulation (CUI) damage on fixed pressure equipment and commentary on common mitigation techniques and good engineering practices for external insulation or fireproofing system design and application.

In this article, FFS assessment methods are summarized and practical guidance is offered for qualifying CUI damage on carbon and low-alloy steels.

This article provides insights into the AIV damage mechanism, reviews approaches to calculate the probability of AIV failure in piping, provides design practices to prevent AIV failure, and introduces a RBI approach to evaluate risk of AIV failures.

Corrosion under insulation is a form of external corrosion that is caused by trapped water on insulated surfaces. It is an industry problem affecting equipment in the oil and gas, petrochemical, specialty chemical, fertilizer, and related industries.

Thermal fatigue, a specific form of fatigue driven by varying metal temperature gradients and ensuing differential thermal expansion, is generally most effectively mitigated by reducing the severity of metal temperature gradients.

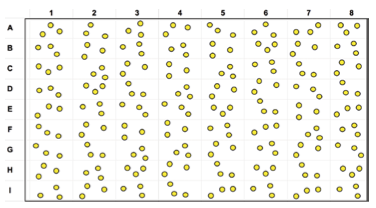

“Condition monitoring location (CML) optimization” is a frequently used term, particularly for piping circuits. Everyone wants their circuits to be “CML optimized,” but what does this truly mean?

Conventionally, three primary fatigue analysis methods have been used to estimate fatigue life; these are the stress-life (S-N) approach, the strain-life (ε-N) approach, and the fracture mechanics (crack growth) approach.

This article reflects the first in a series on damage mechanisms that will appear in this recurring Inspectioneering column entitled “Damage Control.” The inaugural topic discussed in this column is thermal fatigue.

This article provides an overview of brittle fracture, details on several industry failures, and a summary of deficiencies and concerns with current published methods for screening susceptibility of equipment to potential brittle fracture failures.

Much like the equipment and piping they support, structures should be part of a comparable structural integrity (SI) program. This article will examine key components of a comprehensive SI program as an essential companion to an MI program.

This article provides a case study showing the real costs and effects of having a dated engineering standards program, as well as the financial benefits through increased reliability of having a thriving engineering standards program.

Given the concern throughout industry regarding the potential for brittle fracture failures, PWHT guidance to address potential issues arising from the recent changes in PWHT code requirements for carbon steel is examined in this article, and...

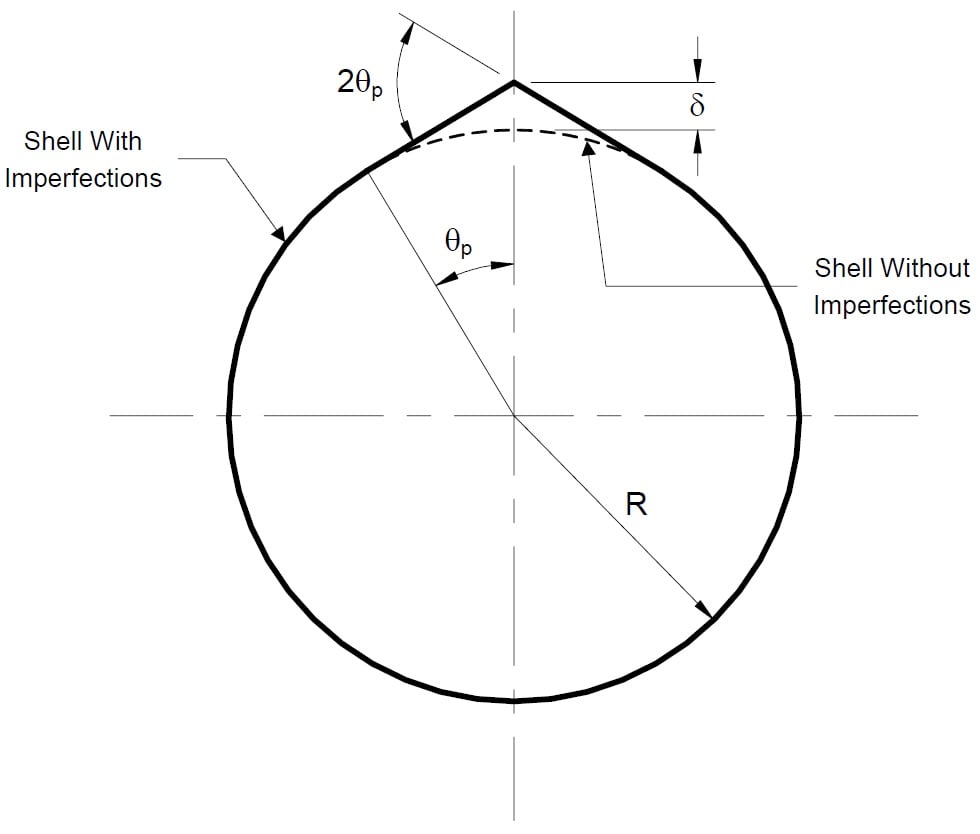

This article summarizes a recent finite element analysis (FEA)-based study that employs creep simulation techniques to investigate the elevated temperature response of piping with peaked longitudinal weld seams.

When was the last time you reviewed your Risk-Based Inspection (RBI) methodology? Are you using calculation procedures for probability of failure, consequence of failure, and risk that haven’t had their basis reviewed in years?

This article addresses a debate mechanical integrity professionals in the O&G and Chemical Processing industries periodically have about how thickness data gathered during a thickness monitoring inspection (TMI) should be recorded.

The tubes of heat exchangers (HX), whether for a shell and tube bundle or an airfin, are typically subject to some form of nondestructive examination (NDE) to try and quantify the remaining wall thicknesses and corrosion rates to help a plant to...

One of the more common inspection monitoring programs for pressure vessels is to perform thickness measurement at Corrosion Monitoring Locations (CMLs) to allow monitoring of minimum thicknesses and provide estimates for corrosion rates. These...

Small bore piping is present in many variations throughout numerous industries. This article will address an incident involving a small bore piping failure that occurred on a 140,000 BPD crude distillation unit in the refining industry.

This article is the fifth of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping; Thickness Monitoring Programs for Internal Corrosion.

Piping failures still represent a frustrating and ongoing problem for processing plants. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment...

This article is the third of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping: thickness monitoring programs for internal corrosion. These articles will discuss...

Piping failures still represent a frustrating and ongoing problem for processing plants. Failures are still commonly reported and contribute to large losses. In the author’s experience, piping represents the highest percentage of fixed equipment...

Piping failures still represent a frustrating and ongoing problem for processing plants (example in Figure 1). Failures are commonly reported and contribute to large losses. As well per the author’s experience, piping still represents the...

This article describes the API Risk-Based Inspection (RBI) methodology for pressure relieving devices (PRDs) as detailed in the soon to be released 2nd edition of API 581 "Base Resource Document On Risk-Based Inspection" This methodology has been...

The following is the final part of a 2-part series outlining the relationship between key operating parameters and corrosion that has been used to develop a set of guidelines to define an operating envelope.

Corrosion and fouling in HF Alkylation Units are closely linked to feed quality and operating conditions. This article outlines the relationship between key operating parameters and corrosion that has been used to develop a set of guidelines to...

E2G | The Equity Engineering Group, Inc. has announced that it has expanded its physical presence across North America with the opening of a new office in Calgary, Alberta.

E2G | The Equity Engineering Group, Inc. establishes a new inspection scheduling methodology to reshape asset integrity and equipment lifecycle planning and management.

Equity Engineering opens two new offices in Katy, TX and Newport Beach, CA, expanding its physical presence across North America.

The Equity Engineering Group, Inc. has received a $1.5 million US Department of Energy grant for developing innovative software for the aging energy industry.

The Equity Engineering Group, Inc. announced today that its API RBI Extension for Intelligent Assets is now available for online purchase on SAP App Center, the digital marketplace for SAP partner offerings.

E2G | The Equity Engineering Group, Inc. announced today that it has acquired CorrSolutions, LLC, a specialty corrosion, materials & inspection engineering consulting firm serving the refining and petrochemical industries.

The Equity Engineering Group, Inc. (E2G) has been given exclusive rights for SIMFLEX-III, Pipe Stress Analysis Software. SIMFLEX-III will complement proprietary programs to meet current industry needs and ensure compliance with newest regulations

This eBook discusses typical damage morphology, inspection methods, and damage assessment and mitigation strategies for sulfidation and high-temperature H2/H2S corrosion.

Join us as we team up with Brian Jack and Kraig Shipley from The Equity Engineering Group to discuss how understanding relevant equipment damage mechanisms can help guide turnaround work scopes and inspection planning activities.

During this webinar, we will cover some of the primary unit layouts used in processing renewable feeds, both in co-processing at existing plants and in standalone 100% renewables units.

This eBook discusses the typical damage morphology and inspection methods used to identify and characterize high-temperature creep, as well as damage assessment and mitigation strategies.

Inspectioneering teams up with The Equity Engineering Group, Inc. to bring you "Improving the Reliability and Performance of Fired Heaters," a one-hour webinar presented by Phil Henry and San Chhotray

This eBook offers practical guidance for, and real examples of, in-service degradation attributed to stress corrosion cracking (SCC). It provides a detailed discussion on SCC detection, characterization and evaluation, and mitigation.

Inspectioneering teams up with The Equity Engineering Group, Inc. to bring you "FFS Assessment of Aboveground Storage Tanks - Common Pitfalls and Case Studies," a one hour webinar presented by Kate Gustoff.

This eBook offers practical guidance for, and real examples of, in-service degradation attributed to wet H2s damage. It provides a detailed discussion on wet H2S damage detection, characterization and evaluation, and mitigation or remediation.

Inspectioneering has teamed up with The Equity Engineering Group to bring you "Pressure Relief for Non-Process Engineers: 10 Things All Plant Personnel Should Know," a one hour webinar presented by Phil Henry, Principal Engineer II at E²G.

Inspectioneering has teamed up with The Equity Engineering Group to bring you "Understanding the CCD/IOW Implementation Process," a 60-minute webinar presented by Brian Jack, Principal Engineer at E²G.

This eBook offers practical guidance for, and real examples of, in-service degradation attributed to corrosion under insulation. It provides a detailed discussion on CUI detection, characterization and evaluation, and mitigation or remediation.

This eBook offers practical guidance for, and real examples of, in-service degradation attributed to thermal fatigue. It provides a detailed discussion on thermal fatigue detection, characterization and evaluation, and mitigation or remediation.

This Asset Intelligence Report on Risk Based Inspection serves as a primer to increase your familiarity with the principles of RBI, RBI implementation, and maintaining an RBI program.