Becht

Company Profile

Becht provides technically excellent engineering solutions, plant services, and software tools to our worldwide clients. We are the company a client will go to when they need the job done right. We are a growing and profitable company, responsive to client needs, committed to excellence, and poised to capture new and interesting opportunities.Founded in 1964 by Charles Becht III, Becht began as a consulting company that served industrial clients and the building sector. In the five decades since its inception, the company’s focus has shifted to serve the energy sector. Becht now provides engineering consulting, plant services, and software tools to the energy sector, including upstream and downstream oil and gas (encompassing both refining and production), petrochemical, chemical, industrial gas, fossil, and nuclear power, as well as specialized support for innovative technologies including direct coal liquefaction, biomass conversion, and other alternative energy processes.

Corporate Headquarters

22 Church St

Liberty Corner, NJ 07938 USA

908-580-1119

Corrosion and Materials

Becht has industry-leading corrosion and metallurgical experts with significant owner-operator experience covering the refining, petrochemical, and chemical industries. Becht's expertise is in a wide rang of materials including metals, refractories, and non-metallics.

Reliability

Becht's reliability team doesn’t believe in operating in silos and is not afraid to look at all aspects (process, IEAC, mechanical, C&M, rotating, etc.) of Equipment, Units, Plants, and Fleets to drive best in class performance.

Process Technology

Becht’s expertise includes equipment, unit, and technology-specific knowledge gained over our expert’s long careers typically with owner/operator corporations. This combined with a true technology-agnostic approach gives the client the right solution for the right problem.

Turnaround Support

Becht offers independent Cold Eye reviews of turnaround goals, scope, work schedules and cost at critical times relative to the turnaround's success. Becht utilizes industry experienced turnaround professionals with significant turnaround management and planning experience to lead reviews.

Becht Blogs

The Becht Blog page consists of interesting articles relating to the various services, industries, and research & development efforts of Becht.

Becht Team

Becht consists of world-class resources providing unparalleled engineering solutions along with many world-class technical specialists, with positions in over 125 positions in ASME, API and ASTM Codes and Standards Committees.

Becht's Inspectioneering Content

Our conversation delved into his journey, expertise, and insights into asset integrity and reliability, as well as nuances related to their application in Asia-Pacific.

It is important to know what damage mechanisms to look for and where to look for them. We will review the link between damage mechanism assignments and RBI.

A look at common reliability issues to help give perspective on where issues may be waiting and how to handle them when they arise.

Leveraging and combining the correct inspection tools on complex problems can yield the best overall data and understanding of actual conditions.

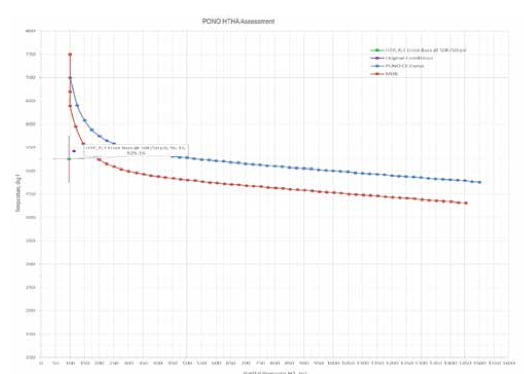

This article describes HTHA predictive modeling advances that are designed to demonstrate a direct integration with inspection such that modeling and inspection can be leveraged together in a way never done before.

Complex problems require collaboration between process, operations, maintenance, inspection, and engineering. It is important to establish a sense of trust in your organization and work to avoid situations where "dynamic tension" is a way of life.

Quantifying corrosion for different crude fractions allows planners the ability to mix and match crude blends alternatively to achieve pre-set metal loss and reliability goals. This flexibility has significant implications for extensive cost savings.

In order to thrive, companies need to maintain top-tier optimization and run equipment safely, reliably, and aggressively. Leveraging highly accurate thermography is one piece of the puzzle to help with these shifts.

This is the first article in a new column. In each article, the author will explore how different parts of organizations can partner to discover new efficiencies, improved equipment integrity, and opportunities to capture additional margin.

IOWs are an important component of a world-class mechanical integrity program. In order to have a robust IOW program, the integration of IOWs into other areas of PSM is critical. This article provides four concrete examples of integration.

This article presents a model to better predict the corrosivity of hot crude oil streams, which is based on open literature going back for almost 60 years and incorporates published information from joint industry projects (JIPs).

Nelson curves, which are the foundation of the industry’s HTHA programs, can be tied to mechanistic models from several sources, allowing the recreation of Nelson curves for different operational histories and time durations.

When paired with the right software, the RBWS process can lead to significant reductions in turnaround work scopes. However, some software tools have distinct advantages over others.

A refinery or process facility FEMI program consists of eight Pillars that are fundamental to achieve FEMI excellence. This article describes these Pillars in detail and suggests what distinguishes good Pillars from those that are less than adequate.

Developing a comprehensive turnaround (TA) work scope for process equipment is a critical step for achieving a facility's business goals. Risk Based Work Selection is a proven process for prioritizing and optimizing planned work for an impending TA.

Risk Based Work Selection (RBWS) is an industry best practice used to help refiners better-manage the safety and reliability of operations for a facility. When properly conducted, RBWS can help refiners optimize major turnaround projects.

Most plants have pieces of equipment with chronic problems that impact profitability due to the frequency of outages, cost of repairs, and lost production. It is critical that specific actions are taken to identify and eliminate these “Bad...

Read a firsthand account of how organizing Process, People, Plant, and Performance can reveal breakdowns in your corrosion management practices and drive down corrosion related leaks.

This article provides background on HTHA, discusses some current developments in HTHA inspection and mitigation, and describes how one refiner is instituting an HTHA risk management plan for its refineries along with challenges they have encountered.

With the publication of API RP 579 For Fitness-For-Service and the planned publication of API RP 580 for Risk Based Inspection in 2001, these technologies will find increasing application in maintenance and inspection planning.

The release of API RP579 will bring about some changes to other existing API standards. The plan is to offer an integrated suite of API standards, where information is presented once and the other documents refer and are linked to that information.

Becht announces the launch of its training program on the 5th edition of API Recommended Practice (RP) 751, Safe Operation of Hydrofluoric Acid Alkylation Unit.

Becht is pleased to announce the official launch of the Becht Joint Industry Project on High Temperature Hydrogen Attack: Comprehensive Life Management of HTHA Susceptible Equipment.

Becht is pleased to introduce Becht Industrial Group to its trusted clients. Becht Industrial Group (BIG) was formed in 2021 as a mechanical contractor specializing in turnarounds, major maintenance activities, and other schedule-driven projects.

Becht announced the official incorporation of its legal entity Becht Europe B.V. in The Netherlands with its office in The Hague. This will enable better service for Becht's clients in Europe, Middle East and Africa.

Becht is pleased to announce the grand opening of our The Hague, Netherlands office in June 2020 to serve the EMEA Region. Chris van der Beek, former senior leader within Shell, will serve as Becht's Director, Europe Operations.

With over 30 years of experience in refining and technology licensing working for ConocoPhillips and UOP, Tim has extensive knowledge of chemical and refining processes with much of his career devoted to HF alkylation units.

Becht announces the acquisition of Code Inspection & Testing Co- IR Technologies to bring heater infrared imaging solutions to the refining, petrochemical, and power generation industries.

Becht is pleased to announce the grand opening of our Buenos Aires, Argentina office in February 2020. Mariano Bertaina, former Executive Technical Director of the Axion Refinery, will serve as Becht's Director, LATAM Operations.

Becht Engineering's Dimensional Technology Services division announces that it has agreed to acquire Texas Gulf Coast Engineers (TGCE). For more than 20 years, TGCE has been a leader in advanced dimensional control services.

Clay comes from Phillips 66 Global Refining, where he was the Corporate Director for Mechanical Integrity. For Becht he will work out of the Pono Corrosion and Materials group and serve as a Metallurgical & Corrosion and Mechanical Integrity Expert.

Roger Parakin has more than 35 years industry/facility experience in instrumentation, electrical system design, project management, construction management, DCS/PLC configuration and systems administration.

This partnership, the newly formed Becht Performance Group, a division of Becht Engineering, brings incredible benefits to both current and future clients as they diagnose, assess and manage their most important resources – their people.

Greg was most recently with POWER Engineering in Oradell, NJ and has worked for Independent Power Developer, GPU International, and Exxon Research and Engineering Co.

Bobby brings over 38 years of experience in plant services including organizing engineering teams on daily plant problems, fitness for service, HTHA, coke drum life extension, process optimization, health monitoring and much more.

Becht has experienced outstanding growth and continues to solidify its position as a premier provider of multi-discipline Central Engineering services and serving in the owners’ role for Maintenance, Projects and Turnarounds.

This webinar covers developing corrosion control documents (CCDs), setting integrity operating windows (IOWs), implementing risk-based inspection (RBI), and more.

This white paper from the experts at Becht demonstrates how the use of risk-based work selection can result in significant reductions in turnaround work scope.

This Asset Intelligence Report on high temperature hydrogen attack (HTHA) serves as a primer to increase your familiarity with the causes, susceptible areas, prevention/mitigation strategies, detection methods, and remediation techniques for HTHA.