API RP 581, Risk-Based Inspection Technology, is a recommended practice developed and published by the American Petroleum Institute (API) to provide quantitative risk-based inspection (RBI) methods that support the minimum guidelines presented by API RP 580. This RP was originally published in 2000, and the most recent 3rd Edition was released in April of 2016.

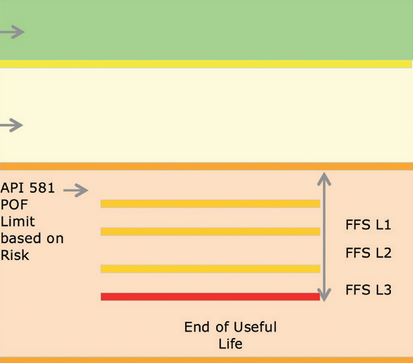

API RP 581 details the procedures and methodology of RBI, an integrated methodology that uses risk as a basis for prioritizing and managing in-service equipment inspection programs by analyzing both the likelihood and the consequences of equipment failure. RBI is a methodology that involves quantitative assessment of the probability of failure (PoF) and the consequence of failure (CoF) associated with each equipment item in a particular process unit. A properly-implemented RBI program categorizes individual pieces of equipment by their risks, prioritizes inspection efforts, and provides guidance for risk mitigation efforts, such as changes in materials of construction, the addition of linings, changes in operating conditions, etc.

API RP 581 has been developed based on the knowledge and experience of several global practitioners of RBI with extensive experience in its implementation. According to API 581, an RBI program has four major goals:

- Identify and measure risk for all covered equipment.

- Impart an accurate understanding of risks and risk drivers.

- Enable effective risk management.

- Reduce risks associated with operating processing facilities.

Related Topics

- API 560 - Fired Heaters for General Refinery Service

- API 579-1/ASME FFS-1 - Fitness-For-Service (FFS)

- API 594 - Check Valves: Flanged, Lug, Wafer, and Butt-Welding

- API 620 - Design and Construction of Large, Welded, Low-Pressure Storage Tanks

- API 650 - Welded Tanks for Oil Storage

- API 660 - Shell-and-Tube Heat Exchangers

- API 661 - Petroleum, Petrochemical, and Natural Gas Industries Air-Cooled Heat Exchangers

- API RP 1160 - Managing System Integrity for Hazardous Liquid Pipelines

- API RP 1173 - Pipeline Safety Management Systems

- API RP 1176 - Assessment and Management of Cracking in Pipelines

- API RP 1188 - Hazardous Liquid Pipeline Facilities Integrity Management

- API RP 538 - Industrial Fired Boilers for General Refinery and Petrochemical Service

- API RP 571 - Damage Mechanisms Affecting Fixed Equipment in the Refining Industry

- API RP 572 - Inspection of Pressure Vessels

- API RP 573 - Inspection of Fired Boilers and Heaters

- API RP 574 - Inspection Practices for Piping System Components

- API RP 575 - Inspection Practices for Atmospheric and Low Pressure Storage Tanks

- API RP 576 - Inspection of Pressure-Relieving Devices

- API RP 577 - Welding Processes, Inspection, and Metallurgy

- API RP 578 - Material Verification for New and Existing Alloy Piping

- API RP 580 - Risk Based Inspection (RBI)

- API RP 583 - Corrosion Under Insulation and Fireproofing

- API RP 584 - Integrity Operating Windows

- API RP 585 - Pressure Equipment Integrity Incident Investigation

- API RP 651 - Cathodic Protection of Aboveground Petroleum Storage Tanks

- API RP 75 - Safety and Environmental Management System for Offshore Operations

- API RP 751 - Safe Operation of Hydrofluoric Acid Alkylation Units

- API RP 754 - Process Safety Performance Indicators for the Refining and Petrochemical Industries

- API RP 934 - Materials and Fabrication of Heavy Wall Pressure Vessels for High-Pressure Hydrogen Ser

- API RP 939-C - Guidelines for Avoiding Sulfidation (Sulfidic) Corrosion Failures in Oil Refineries

- API RP 941 - Steels for Hydrogen Service at Elevated Temperatures and Pressures

- API RP 970 - Corrosion Control Documents

- API RP 982 - Inspection and Assessment of Refractory Linings

- International Organization for Standardization (ISO)

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition