Flanges are external ridges on beams or pipes that allow them to be attached to other objects. In the process industries, flanges are most often important in the context of pipelines and piping. Sections of pipe are able to be bolted or welded together at these flanges; allowing for easier transportation, assembly, installation, and/or disassembly than if they were constructed as one big section. By making them easier to disassemble, maintenance, inspection, and cleaning activities can be conducted without affecting large portions of the pipe system.

Some of the most common types of flanges in the industry are welding neck flanges, slip on flanges, socket weld flanges, lap joint flanges, threaded flanges, and blind flanges. They can be made of a number of different materials such as stainless steel, cast iron, aluminium, brass, bronze, or plastic, among others. Usually the flange material is the same as the pipe itself.

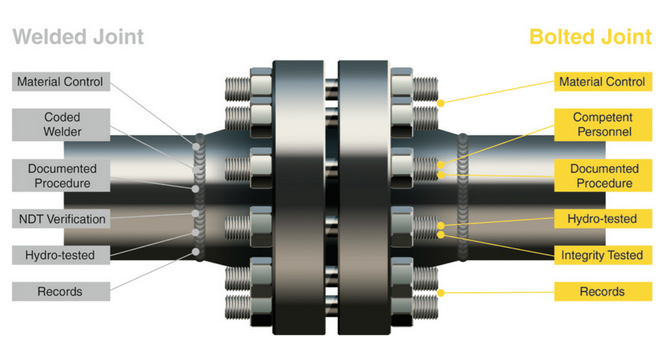

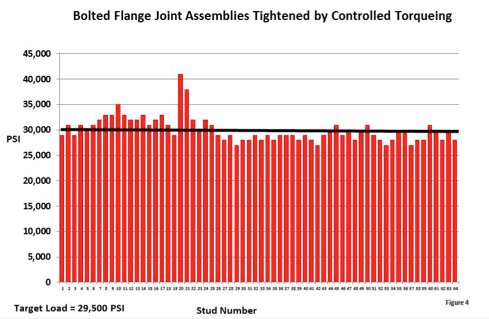

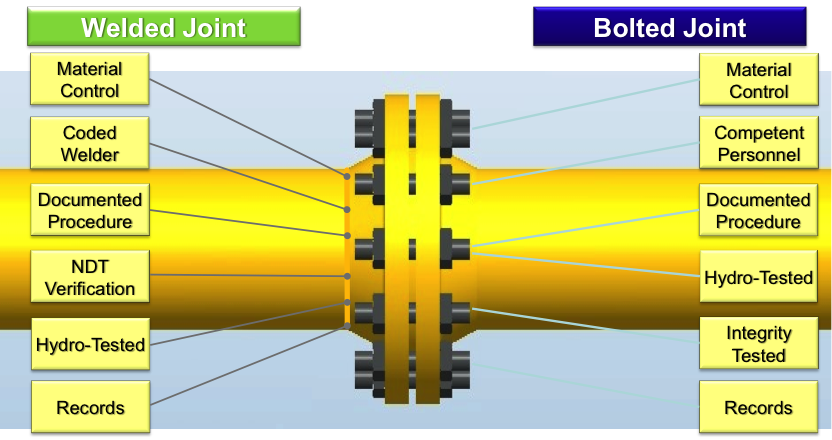

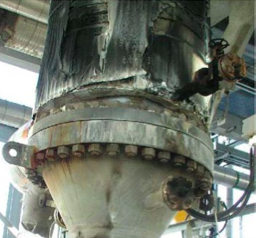

The area where two pipes are joined together by a flange is known as a flange joint. This is a critical area for managing the integrity of a piping system. Leaks can delay production start up, cause unplanned shutdowns, or cause significant safety incidents. All of which, could have a substantial impact on the budget. This is why effective joint integrity management practices are so important.

Related Topics

- Aboveground Storage Tanks (ASTs)

- Boiler Tubes

- Boilers

- Bolts

- Coker Units

- Cooling Towers

- Crude Distillation Unit (CDU)

- Deaerators

- Fired Heaters

- Fixed Equipment

- Flare Systems

- Furnace Tubes

- Glass-lined Equipment

- Heat Exchangers

- HF Alkylation Units

- Hydrocracking Unit

- Hydrotreater

- Piping

- Pressure Relieving Devices (PRDs)

- Pressure Vessels

- Rotating Equipment

- Vacuum Distillation Unit (VDU)

- Valves

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition