Furnaces are critical pieces of equipment that can have a major impact on process unit safety, reliability, and economics. Therefore, Furnace Tube inspection and maintenance are essential activities for effective asset integrity management at any refinery or petrochemical plant.

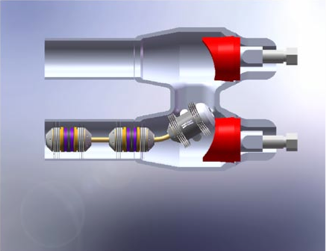

Furnace tube life and integrity are impacted by several degradation mechanisms depending on the type of service, operating conditions, and the material of construction. In most cases, creep is the mechanism of major concern, especially in areas of heavy coking. However, tube failures are usually associated with a combination of multiple mechanisms, including carburization, oxidation, sulfidation, erosion, low toughness, and sigma phase formation. This last mechanism specifically affects austenitic stainless steel tubes.

Mechanical integrity personnel, including unit inspectors, site inspection authorities, reliability, fixed equipment, and material/corrosion engineers, are responsible for the reliable operation of furnace tubes. Below are some recommendations for inspectors and engineering practitioners to follow as part of their tube inspection/assessment program covering all site furnaces.

- Gather representative inspection data to set variables impacting remaining life calculations, such as corrosion rates, diametral growth, and time increment during analysis.

- Perform on-stream monitoring, including routine visual inspection; looking for sagging, flame impingement, broken or missing hangers, broken tubesheets, etc.

- Perform infrared surveys (IR) based on furnace history and operation, and set intervals using inspection history and engineering assessment. Schedule a survey before each major shutdown.

- During turnarounds, regardless of tube metallurgy type, perform thorough thickness measurements and bulging checks (visual, lamping, strapping, and/or advance crawlers), especially at locations where IR indicates elevated temperatures. Use a magnet as a quick screen to check for carburization of stainless steel and Incoloy 800/800HT tubes. Use radiograph inspection to check for localized damage from erosion in return bends and outlets. Perform inspections in furnaces tubes of ferritic-to-austenitic dissimilar welds.

- Become familiar with furnace design and construction, understanding their effects on tube integrity and life span.

- Identify life limiting degradation mechanisms that might be contributing to shorter tube life.

- Determine and set reasonable operating limits for heater tube metal temperatures (determination should consider creep, as well as other damage mechanisms such as sulfidation, carburization, embrittlement, etc.).

- Complete remaining life assessment baseline and readdress whenever thermocouple readings or IR results consistently approach or exceed those limits. Assessment should be considered at least every turnaround interval. Define representative operating conditions for the tubes, which should include past, present, and future expected values of temperature, pressure, and other loads.

- Select proper material creep strength and ductility information to perform remaining life assessments; use of industry data or literature might not be always the right option, and when it is, it might provide conservative or non-conservative results. Extract samples and perform metallurgical evaluation and mechanical testing when possible.

- Set a strain limit for sample removal (mechanical testing and metallographic evaluation) and retirement. Consider tube samples and/or advanced NDE on critical furnaces to check for degradation after 10-15 years in service.

- Keep records of all inspections, modifications, changes, repairs, evaluations, testing, and engineering assessments done.

Related Topics

- Aboveground Storage Tanks (ASTs)

- Boiler Tubes

- Boilers

- Bolts

- Coker Units

- Cooling Towers

- Crude Distillation Unit (CDU)

- Deaerators

- Fired Heaters

- Fixed Equipment

- Flanges

- Flare Systems

- Glass-lined Equipment

- Heat Exchangers

- HF Alkylation Units

- Hydrocracking Unit

- Hydrotreater

- Piping

- Pressure Relieving Devices (PRDs)

- Pressure Vessels

- Rotating Equipment

- Vacuum Distillation Unit (VDU)

- Valves

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition