Fixed Equipment, sometimes also known as static equipment, is a term generally used to describe non-moving equipment in the oil and gas and process industries. Some examples include things like pressure vessels, heat exchangers, piping, storage tanks, valves, pressure relieving devices, boilers, furnaces/heaters and structures. On the other hand, fixed equipment does not include things such as pumps, compressors, turbines, electrical equipment, or instrumentation (I&E), even though they typically don't move.

The risks associated with fixed equipment are higher compared to other equipment types because of the sheer number of equipment pieces and quantity of stored fluid. In a typical refinery or petrochemical facility, a significant portion of the capital/maintenance cost and reliability events or failures are associated with fixed equipment. A significant percentage of industry incidents that have resulted in injuries or asset loss also have been associated with fixed equipment.

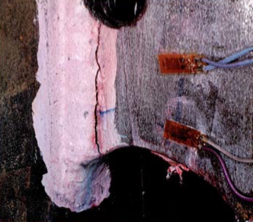

Fixed equipment is often subjected to fairly extreme operating conditions and varying damage mechanisms. In most cases, the damage is not immediate and damage rates are not linear. A good example of this is corrosion under insulation (CUI) damage, which can develop over time, but is not immediately obvious.

Unlike other types of equipment, fixed equipment doesn’t have complex sensors that can be used to monitor for corrosion and damage in real time. For this reason fixed equipment must be monitored by inspections at fixed intervals. This is why it’s so important to have a reliability plan in place for all fixed equipment.

Fixed equipment is an essential part of every plant and facility, so it is important to keep it in good condition.

Related Topics

- Aboveground Storage Tanks (ASTs)

- Boiler Tubes

- Boilers

- Bolts

- Coker Units

- Cooling Towers

- Crude Distillation Unit (CDU)

- Deaerators

- Fired Heaters

- Flanges

- Flare Systems

- Furnace Tubes

- Glass-lined Equipment

- Heat Exchangers

- HF Alkylation Units

- Hydrocracking Unit

- Hydrotreater

- Piping

- Pressure Relieving Devices (PRDs)

- Pressure Vessels

- Rotating Equipment

- Vacuum Distillation Unit (VDU)

- Valves

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition