Background

In the current economic environment, there is increasing pressure on petrochemical refineries and delivery systems to be more productive and to minimize unscheduled shutdowns due to leakage. Leakage can occur from either the piping itself or the joints of the pipes. In a refinery there are several thousands of feet of piping and associated joints, as shown in the photograph presented in Figure 1. Petrochemical leaks don’t only cost the companies money for the time and material to repair a leak, but also to remediate the areas affected and the institution of stricter controls. Because of this pressure, the involved companies are looking to replace the current monitoring scheme with a more effective and cost efficient risk based inspection (RBI) program. The backbone of such a program is the concept of being able to quickly identify the most serious conditions so that they can be attended to immediately, and conditions of lesser concern can be relegated to remediation at a future shutdown.

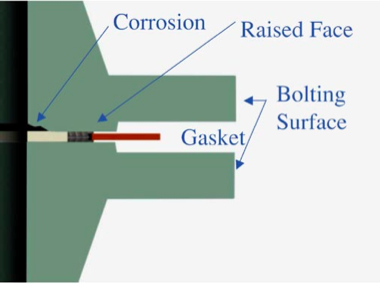

One area where leakage is a concern is at the bolted flange joints. Each joint consists of two mating flanges with a gasket material between them, Figure 2. Leakage at these joints are a result of the corrosive material being transported in the lines attacking the steel flanges and removing material from the sealing surfaces to such an extent that the seal is compromised and leakage occurs. In the petrochemical refinery process, the HSE concerns for some of the materials are quite severe, and therefore any leakage is of grave concern.

The current monitoring philosophy relies heavily on the physical disassembly of the joints to do a visual inspection of the surfaces. Due to the time involved to disassemble the joints, perform the visual inspection and reassembly, a push has been put forth to supplement the visual inspections with a non-invasive technique, such as ultrasonics. The approaches have ranged from simple manual single element raster type inspection to complex phased array scanner based systems. The single element approach provides simplicity in operation, but complexity in analysis. A phased array scanner based system sacrifices simplicity in operation for reduced data analysis complexity. Within the range of possible ultrasonic techniques, there does not exist a simplistic manual phased array approach. To answer this need, GEIT has begun to develop a solution utilizing the PHASOR –XS ® in conjunction with manual manipulation of a phased array probe. This solution provides the best of both worlds (i.e., ease of operation and simplicity of data analysis).

Discussion

The evaluation of corrosion on the sealing surface of a flange can be accomplished from three different surfaces (bolting surface, taper, and outside diameter of the flange). There is not one that provides the perfect solution. Each one has drawbacks and advantages. The drawbacks associated with scanning from the bolting surface is that there will be areas that cannot be inspected because of the bolt hole and studs, and also, this approach hinders an assessment of the actual amount of material loss from the bolt surface, because of the angle of the beams impinging on the surface of concern. An inspection from the taper region has the drawback that different curved wedges need to be developed for each different taper condition, and if full coverage is required then a custom low profile probe and wedge are needed to fit behind the studs. From the outer diameter of the flange, the drawbacks are the need for an encoded scanning device to maintain the proper probe position while rotating the probe around the circumference of the flange. Also, if wall progression assessment is required, this technique requires full RF waveform capture to generate a C-scan type image from which to assess that progression. With the need for scanning mechanisms for this technique an inherent limitation to its use is the proximity of the joints to one another. In certain locations the piping runs may be such that a scanning mechanism cannot fit into the space envelope available. Even with the limitations of the ultrasonic techniques, the petrochemical industry has been relying more and more on it because of the additional information that is provided to help the owners minimize their liabilities.

In an attempt to bridge the gap between the simplest conventional single element approach and the more comprehensive, We began a study designed to provide a viable phased array flange face inspection solution that is highly portable, and simple to use for an experienced phased array inspector. The approach was centered on utilizing the system along with both standard and custom designed wedges as the data acquisition platform, and the Rhythm software solution for reporting and archiving the results. The development of a full solution (i.e., one that covers data acquisition, analysis, reporting and archival) is a benefit to a customer because inspection can be performed in a logical fashion and the results are available for future reference for planning purposes. Presented below will be a brief discussion of the approaches pursued to arrive at the proposed solution, and then that will be followed by a discussion of the results for each approach and the recommended action that are needed to be taken to achieve a field deployable solution.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.