The Oil and Gas industry is commonly divided into the three major sectors: Upstream, which includes the exploration and production (E&P) of hydrocarbons, primarily crude oil and natural gas; Midstream, which includes the transportation and storage of oil and gas; and Downstream, which refers to the refining and processing of crude oil and natural gas, as well as the marketing and distribution of petroleum-based products, including gasoline, diesel, jet fuel, natural gas liquids, and many others.

Oil and Gas Exploration

O&G exploration involves the search for new hydrocarbon reservoirs, either onshore or offshore, to evaluate their viability of drilling and extraction. Exploration typically begins with geological and geophysical surveys, including seismic studies, to identify potential hydrocarbon-bearing formations beneath the Earth's surface. Seismic data provides detailed information about subsurface structures, helping geologists pinpoint areas with the potential for oil and gas reservoirs. Once a promising area is identified, exploration wells are drilled to confirm the presence of hydrocarbons. These wells can be shallow or deep, depending on the geological characteristics of the target reservoir. The extracted core samples and data from these wells help geologists and engineers assess reservoir size, composition, and pressure. This information helps estimate the reservoir's production potential and determine the optimal drilling and production techniques. Advanced 3D and 4D seismic interpretation technologies have revolutionized exploration operations, enabling a more accurate assessment of reservoir characteristics and improved targeting of drilling locations.

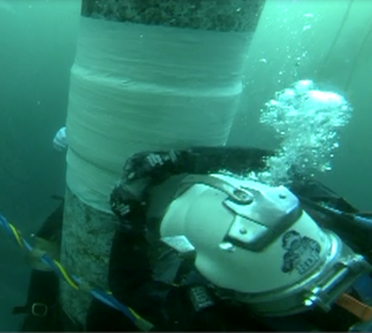

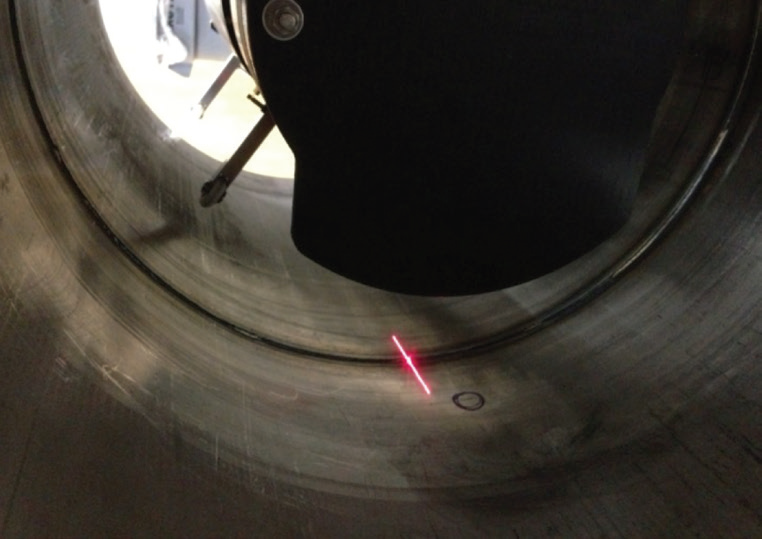

Oil and Gas Production

O&G production commences once a viable hydrocarbon reservoir is discovered, and involves drilling and extracting crude oil and natural gas from reservoirs located onshore or offshore. Production wells vary in complexity, from conventional vertical wells to more advanced horizontal and directional wells. The choice of drilling technique depends on reservoir characteristics and economic considerations. Production wells are equipped with various downhole tools and components to control the flow of hydrocarbons, including casing, tubing, and wellhead equipment. Hydraulic fracturing (aka, fracking) is a technique used to enhance production from tight formations by creating fractures in the rock to allow hydrocarbons to flow more easily. Enhanced oil recovery methods, such as water injection, gas injection, and chemical flooding, may be employed to increase recovery from mature reservoirs.

The Upstream O&G Industry

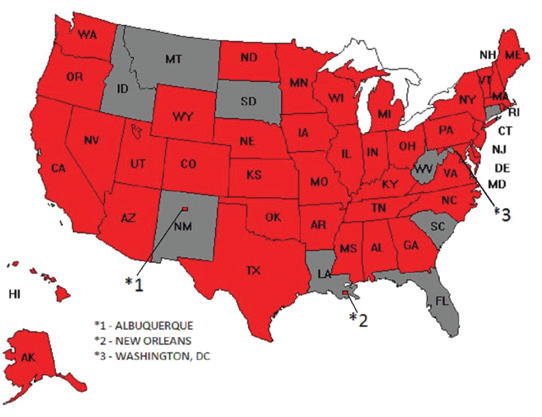

The oil and natural gas industry supports 10.3 million jobs in the United States and accounts for nearly 8 percent of our nation’s Gross Domestic Product. The upstream sector is a critical component of the global energy industry, playing a pivotal role in meeting the world’s energy demands, driving economic growth, and shaping geopolitics. In 2022, global oil production stood at approximately 100 million barrels per day (mb/d), with the top 5 oil producing countries being:

- United States (20.21 mb/d)

- Saudi Arabia (12.14 mb/d)

- Russia (10.94 mb/d)

- Canada (5.70 mb/d)

- China (5.12 mb/d)

In 2022, the U.S. was also the world’s biggest natural gas producer at approximately 98 billion cubic feet per day (BCF/d), followed by Russia (70 BCF/d), Iran (26 BCF/d), China (21 BCF/d), and Qatar (18 BCF/d). The shale revolution over the last 20 years, driven by hydraulic fracturing and horizontal drilling technologies, has transformed the U.S. energy landscape. Key shale formations like the Permian Basin and the Eagle Ford in Texas, the Bakken in North Dakota, and the Marcellus in the Northeast have contributed significantly to the U.S. becoming one of the largest oil and natural gas producers in the world.

Upstream Regulations

Environmental and safety regulations are central to upstream oil and gas operations. In the United States, companies must adhere to stringent state and federal standards for emissions control, spill prevention, process safety, and environmental impact mitigation. Sustainability initiatives, including reducing greenhouse gas emissions and minimizing environmental footprint, have also gained prominence in recent years.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition